Honda Integra JDM

Мануал для тигры, может кому понадобиться

Gusmanjdm

Был 1 день назад

Ильгиз Айдарович

Я езжу на Honda Integra JDM (до этого — LADA 2109)

Нефтекамск, Россия

Братья хондаводы может кому понадобиться мануал для наших тигр Мануал Integra

9 января 2015

Метки: своими руками

7

Ранее #Губа, или наконец купил

Далее Неприятность или понедельник

Разместить рекламу

Реклама

Машины в продаже

Комментарии

7

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Войти

Зарегистрироваться

rednakleika

Я езжу на Honda Integra (DC1/DC2)

Скачала но файл пустой 🫠🥲

5 месяцев

Gusmanjdm

Автор

Я езжу на Honda Integra (DC1/DC2)

Странно, найду на компе скину 😄

5 месяцев

somebody

Несуществующий пользователь

Без машины

полезная книженция, давно ещё скачивал её)

8 лет

Gusmanjdm

Автор

Я езжу на Honda Integra (DC1/DC2)

Да хорошая книжка) помогает

8 лет

somebody

Несуществующий пользователь

Без машины

я не помню что там искал, но вроде что то да нашел)

8 лет

Flap

Я езжу на Ford Fusion

у меня такой в бумажном виде)) ещё от цивика остался)

8 лет

Gusmanjdm

Автор

Я езжу на Honda Integra (DC1/DC2)

Жалко у меня нет такого)

8 лет

Инструкции по ремонту |

||||||

|---|---|---|---|---|---|---|

| Описание | Кузов | Двигатель | Файл | Размер | Формат | Язык |

| Инструкция по ремонту Acura Integra | DC2, DC4, DB7, DB8 | B18B1 (140 сил), B18C1 (170 сил), B18C5 (195 сил) | Acura Integra (98-01) Service Manual.pdf | 54 MB | PDF* | Английский |

| Инструкция по ремонту Acura RSX (Honda Integra) | DC5 | K20A2 (200 сил), K20A3 (160 сил) | Acura RSX (02-03) Service Manual.pdf | 40 MB | Английский | |

| Honda Integra Acura RSX (01-07) Rus.pdf | 32 MB | Русский | ||||

| Инструкция по ремонту Acura TSX (Honda Accord) | CL9 | K24A2 (200 сил) | Acura TSX.zip | 252 MB | Английский | |

| Инструкция по ремонту Honda Civic | EG/EH | D15B7 (100 сил), D15B8 (70 сил), D15Z1 (90 сил), D16Z6 (125 сил) | Honda Civic 92-95 Service Manual.pdf | 88 MB | Английский | |

| Инструкция по ремонту Honda Civic | EK/EJ | D16Y5 (114 сил), D16Y7 (105 сил), D16Y8 (125 сил), B16A2 (160 сил) | Honda Civic EJ6, EJ7, EJ8 (96-00) Service Manual.pdf | 69 MB | Английский | |

| Инструкция по ремонту Honda Civic, Acura Integra | EK/EJ, DC2, DC4, DB7, DB8 | KD16Y5 (114 сил), D16Y7 (105 сил), D16Y8 (125 сил), B18B1 (140 сил), B18C1 (170 сил), B18C5 (195 сил) | Honda_Civic_Acura_Integra_1994.zip | 220 MB | EXE | Русский |

| Инструкция по ремонту Honda Civic | EP3 | K20A3(160 сил) | Honda Civic EP3 (02-03) Service Manual.pdf | 28 MB | Английский | |

| Инструкция по ремонту Honda Civic | ES/EM/EU/EP | D14Z(4-5), D15Y(2-6), D16W(7-8), D16Y(1-3), D17A(1-9), D17Z1, K20A2 | Civic01-05.zip | 165 MB | EXE | Английский |

| Инструкция по ремонту Honda S2000 | AP1 | F20C1 (240 сил) | Honda S2000 (00-03) Service Manual.pdf | 28 MB | Английский | |

| Инструкция по ремонту Honda CRX | ED9 | D16A6 (110 сил), D16A7 (110 сил), D16A8 (122 силы), D16A9 (130 сил) | Honda CRX 90 Service Manual.pdf | 16 MB | Английский | |

| Инструкция по ремонту Honda CRX | EE8 | B16A1 (150 сил), Special for MSSFM  |

Honda CRX 90 Service Manual B16A1 Engine.pdf | 7 MB | Английский | |

Инструкции по эксплуатации |

||||||

| Описание | Кузов | Двигатель | Файл | Размер | Формат | Язык |

| Инструкция по эксплуатации Honda Civic | EK/EJ | D14, D15, D16, B16 | Honda Civic Gen6 (96-00) Rus.zip | 12 MB | GIF | Русский |

| Инструкция по эксплуатации Honda Accord | CL/CM | K20A6 (155 сил), K24A3 (190 сил) |

Accord_guide.pdf Accord_MFD_ru.pdf |

7 MB | Русский | |

| Инструкция по эксплуатации Honda Civic | FN2 | K20Z3 (201 сила) | Civic_Type_R_guide.pdf | 17 MB | Русский |

*Для просмотра документов в формате PDF необходим Adobe Reader.

Отзывы и предложения можно оставлять здесь.

Вернуться на форум

Welcome to ManualMachine

You have been successfully registered

We have sent a verification link to to complete your registration.

If you can’t find the email, check your Junk/Spam folder.

- Buy Points

- How it Works

- FAQ

- Contact Us

- Questions and Suggestions

- Users

You can only view or download manuals with

Sign Up and get 5 for free

Upload your files to the site. You get 1 for each file you add

Get 1 for every time someone downloads your manual

Buy as many as you need

View and download manuals available only for

Register and get 5 for free

Upload manuals that we do not have and get 1 for each file

Get 1 for every download of your manual

Buy as much as you need

Get your hands on the complete Honda factory workshop software

Locations

ABS Main Relay: Locations

Right Front Of Engine Compartment

Page 178

Circuit Identification for In-Line and Fuse Box Connectors Part 4

Use the charts to help diagnose multiple symptoms in separate circuits which could be caused by a

single problem in a connector shared by those circuits. Here’s how that chart could help you find

such a problem:

1. Pick one of the multiple symptoms and look up the schematic for that circuit. 2. Make a list of all

in-line and fuse box connectors in that schematic (include page numbers). 3. Then, in the chart,

look up each connector on your list to see if circuits related to the other symptoms run through one

of them. If they do, inspect

that connector for the problem.

Example: The horn, A/C, and the right headlight don’t work. List all in-line and fuse box connectors

in the horn circuit and then check the chart (See Sample). You find that C211 is common to the A/C

circuit and the headlight circuit, so you inspect C211 and find the problem: bent terminals.

Light Flasher Relay

101. Below Left Side of Dash (with Security)

Page 181

Body Control Module: Diagram Information and Instructions Component Locations

To see where a component or connector is located on the car, look up its photo number in the

Component Location. The photo will also tell you the color of the connector, and how many cavities

it has.

If there is no photo number below or beside a connector, ground, or terminal number, look up that

connector, ground, or terminal number in the appropriate Connector Identification Chart. The chart

will tell you the color of a connector, how many cavities it has, where it’s located, and what

component or harness it connects to. On the page opposite that chart you’ll find an illustration of

the related harness.

Page 163

Fuse-To-Components Index Image 6-2

Page 15

Circuit Identification for In-Line and Fuse Box Connectors Part 4

Use the charts to help diagnose multiple symptoms in separate circuits which could be caused by a

single problem in a connector shared by those circuits. Here’s how that chart could help you find

such a problem:

1. Pick one of the multiple symptoms and look up the schematic for that circuit. 2. Make a list of all

in-line and fuse box connectors in that schematic (include page numbers). 3. Then, in the chart,

look up each connector on your list to see if circuits related to the other symptoms run through one

of them. If they do, inspect

that connector for the problem.

Example: The horn, A/C, and the right headlight don’t work. List all in-line and fuse box connectors

in the horn circuit and then check the chart (See Sample). You find that C211 is common to the A/C

circuit and the headlight circuit, so you inspect C211 and find the problem: bent terminals.

Locations

Power Door Lock Relay: Locations

Front Of Driver’s Door

Front Of Driver’s Door

Page 104

Blower Motor Relay: Testing and Inspection

RELAY TEST

Normally-Open Type 1. Remove the power relay from its socket.

2. Check continuity between relay terminals.

— There should be continuity between the A and C terminals when power and ground are connected

to the B and D terminals.

— There should be no continuity when power is disconnected.

Page 162

Fuse-To-Components Index Image 6-1

Page 32

Splices

Locations

Ignition Shut Down Relay (For Antitheft): Locations

Below Left Side Of Dash

Page 27

Terminals — T

Page 48

General Module: Description and Operation

INTEGRATED CONTROL UNIT

An integrated control unit, located in the left kick panel, integrates the functions of the key-in/seat

belt reminder, side marker light flasher, wiper/washer, lights-on reminder, rear window defogger

timer, brake system light bulb check, and engine oil pressure indicator flasher circuits.

NOTE: Different wires with the same color have been given a number suffix to distinguish them (for

example, GRN/RED1 and GRN/RED2 are not the same).

Page 19

General Module: Diagram Information and Instructions Ground Distribution Schematics

This sample Ground Distribution schematic shows all of the components that share two ground

points.

Page 156

58. Behind Dashboard Lower Cover

Page 21

From Fuses to Relays and Components

The second half of Power Distribution shows the wiring «From Fuses to Relays and Components.»

This can speed your troubleshooting by showing which circuits share fuses. If Power Distribution

shows that an inoperative circuit and another circuit share a fuse, check a component in the other

circuit. If it works, you know the fuse is good and power is available to the inoperative circuit.

Page 20

General Module: Diagram Information and Instructions Power Distribution Schematics

Power Distribution schematics show how power is supplied from the positive battery terminal to

various circuits in the car. Refer to the Power Distribution to get a more detailed picture of how

power is supplied to the circuit you’re working on.

From Battery to Ignition Switch, Fuses, and Relays

Individual circuit schematics begin with a fuse. The first half of Power Distribution, however, shows

the wiring «upstream» between the battery and the fuses.

Page 99

3. Inspect the connector and socket terminals to be sure they are all making good contact.

If the terminals are bent, loose or corroded, repair them as necessary, and recheck the system. If

the terminals look OK, make the following input tests at the connector. If any test indicates a problem, find and correct the cause, then recheck the system.

— If all the input tests prove OK, the control unit must be faulty; replace it.

Page 116

Blower Motor Speed (2 Of 2)

Page 134

60. Behind Dashboard Lower Cover

Testing For a Short to Ground With A Test Light or DVOM

General Module: Diagnostic Aids Testing For a Short to Ground With A Test Light or DVOM

1. Remove the blown fuse and disconnect the load.

2. Connect a test light or digital volt/ohmmeter (DVOM), switched to the appropriate DC volts

range, across the fuse terminals to make sure voltage

is present. You might have to turn the ignition switch to ON; check the schematic to see.

3. Beginning near the fuse box, wiggle the harness. Continue this at convenient points about six

inches apart while watching the test light or DVOM. 4. Where the test light goes off, or the DVOM

voltage drops to zero, there is a short to ground in the wiring near that point.

NOTE: Always use a DVOM on high impedance circuits. A test light may not glow (even with

battery voltage present).

Page 79

Brake Fluid Pump Relay: Testing and Inspection

RELAY TEST / ABS PUMP MOTOR RELAY

Normally-Open Type 1. Remove the power relay from its socket.

2. Check continuity between relay terminals.

— There should be continuity between the A and C terminals when power and ground are connected

to the B and D terminals.

— There should be no continuity when power is disconnected.

Page 25

Components

Page 159

Under-Hood Fuse/Relay Box (2 Of 2)

21. Right Rear Corner of Engine Compartment

Page 121

Maintenance Reminder Control Module: Testing and Inspection

MAINTENANCE REMINDER UNIT / INPUT TEST

1. With the ignition switch OFF, disconnect the 5-P connector from the reminder unit.

2. Inspect the connector and socket terminals to be sure they are all making good contact.

If the terminals are bent, loose or corroded, repair them as necessary, and recheck the system. If

the terminals look OK, make the following in-put tests at the connector. —

If a test indicates a problem, find and correct the cause, then recheck the system.

— If all the input tests prove OK, the reminder unit must be faulty; replace it.

Page 164

Fuse-To-Components Index Image 6-5

Locations

55. Above Left Kick Panel

Page 165

Relay Box: Application and ID Under-Hood Fuse/Relay Box

Fuse-To-Components View Image 6-3

Page 31

Shielding

Wire Color Abbreviations

Wire Color Abbreviations

Page 70

Trunk / Liftgate Relay: Testing and Inspection

RELAY TEST

Normally-Open Type 1. Remove the power relay from its socket.

2. Check continuity between relay terminals.

— There should be continuity between the A and C terminals when power and ground are connected

to the B and D terminals.

— There should be no continuity when power is disconnected.

Page 175

Body Control Module: Diagram Information and Instructions Circuit Identification For In-Line and

Fuse Box Connectors

Circuit Identification for In-Line and Fuse Box Connectors Part 1

Locations

Body Control Module: Locations

Rear Of Under-dash Fuse/Relay box

Page 42

General Module: Diagnostic Aids Testing For A Short to Ground W/Self-Powered Test Light or

DVOM

1. Remove the blown fuse and disconnect the battery and load.

2. Connect one lead of a self-powered test light or digital volt/ohmmeter (DVOM) (switched to the

lowest «OHMS» range) to the fuse terminal on the

load side.

3. Connect the other lead to a known good ground. 4. Beginning near the fuse box, wiggle the

harness. Continue this at convenient points about six inches apart while watching the test light or

DVOM. 5. If the self-powered test light goes on or the DVOM displays a low reading or no reading

(zero), there is a short to ground in the wiring near that

point.

Locations

54. Above Left Kick Panel

Testing and Inspection

Control Module HVAC: Testing and Inspection

Blower Motor Speed (1 Of 2)

Page 35

General Module: Diagram Information and Instructions Wire Color Codes

The following abbreviations are used to identify wire colors in the circuit schematics:

WHT = White YEL = Yellow BLK = Black BLU = Blue GRN = Green RED = Red ORN = Orange

PNK = Pink BRN = Brown GRY = Gray PUR = Purple LT BLU = Light Blue LT GRN = Light Green

Wire Color Codes

The wire insulation has one color or one color with another color stripe. The second color is the

stripe.

NOTE: Different wires with the same color in the same system have been given number suffixes to

distinguish them (for example, YEL1 and YEL2 are not the same).

Locations

13. Right Front Corner of Engine Compartment

Page 45

General Module: Diagnostic Aids Testing For Voltage Drop

Wires, connectors, and switches are designed to conduct current with a minimum loss of voltage. A

voltage drop of more than one volt indicates a problem.

1. Place the digital volt/ohmmeter (DVOM) in the appropriate DC volts range. Connect the positive

lead to the end of the wire (or to the connector or

switch) closest to the battery.

2. Connect the negative lead to the other end of the wire (or the other side of the connector or

switch). 3. Turn on the components in the circuit. 4. The DVOM will show the difference in voltage

between the two points. A difference, or drop, of more than one volt indicates a problem. Check

the circuit for loose, dirty, or bent terminals.

Page 75

ABS Main Relay: Testing and Inspection

RELAY TEST

Normally-Open Type 1. Remove the power relay from its socket.

ABS Pump Motor Relay

ABS Fail-Safe Relay

2. Check continuity between relay terminals.

— There should be continuity between the A and C terminals when power and ground are connected

to the B and D terminals.

— There should be no continuity when power is disconnected.

Locations

60. Behind Dashboard Lower Cover

Power Relay Test

Radiator Cooling Fan Motor Relay: Testing and Inspection Power Relay Test

Relay Test (Normally-Open Type)

Check for continuity between the terminals.

There should be continuity between the A and B terminals when power and ground are connected

to the C and D terminals.

There should be no continuity between the A and S terminals when power is disconnected.

Type 1

— Condenser Fan Relay

— Radiator Fan Relay

— A/C Compressor Clutch Relay

Type 2

Page 180

connector’s location on the car. Connector cavities are also numbered. The numbering sequence

begins at the top left corner of the connector as seen from either of the viewpoints. Disregard any

numbers molded into the connector housing.

Wires are identified by the abbreviated names of their colors; the second color is the color of the

stripe. Wires are also identified by their location in a connector. The number «2» next to the male

and female wire terminals at C416, for example, means those terminals join in cavity 2 of connector

C416.

A complete description of schematic symbols is as given in «Symbols».

Page 140

Horn Relay: Testing and Inspection

RELAY TEST

Normally-Open Type 1. Remove the power relay from its socket.

2. Check continuity between relay terminals.

— There should be continuity between the A and C terminals when power and ground are connected

to the B and D terminals.

— There should be no continuity when power is disconnected.

Electrical Load Detector Unit

Right Rear Corner Of Engine Compartment

Page 29

Fuses

Testing and Inspection

Power Distribution Relay: Testing and Inspection

RELAY TEST

Normally-Open Type 1. Remove the power relay from its socket.

2. Check continuity between relay terminals.

— There should be continuity between the A and B terminals when power and ground are connected

to the C and D terminals.

— There should be no continuity when power is disconnected.

Type 1

Type 1

Type 2

Type 2

— Power Window Relay

— Radiator Fan Relay

— Blower Motor Relay

— A/C Compressor Clutch Relay

Page 17

connector’s location on the car. Connector cavities are also numbered. The numbering sequence

begins at the top left corner of the connector as seen from either of the viewpoints. Disregard any

numbers molded into the connector housing.

Wires are identified by the abbreviated names of their colors; the second color is the color of the

stripe. Wires are also identified by their location in a connector. The number «2» next to the male

and female wire terminals at C416, for example, means those terminals join in cavity 2 of connector

C416.

A complete description of schematic symbols is as given in «Symbols».

Page 179

Body Control Module: Diagram Information and Instructions Circuit Schematics

Each schematic represents one circuit. A circuit’s wires and components are arranged to show

current flow, from power at the top of the page, to ground, at the bottom.

Other circuits may share power or ground terminals or wiring with the circuit shown. A wire that

connects one circuit to another, for example, is cut short and has an arrowhead at the end of it

pointing in the direction of current flow. Next to the arrowhead is the name of the circuit or

component which shares that wiring. To quickly check shared wiring, check the operation of a

component it serves. If that component works, you know the shared wiring is OK.

All connectors are numbered (C709, C416, etc.). Below each connector number (except those for

components) is the number of a photo showing the

Page 26

Connectors — C

Page 136

— If a test indicates a problem, find and correct the cause, then recheck the system.

— If all the input tests prove OK, the turn signal/hazard relay must be faulty; replace it.

Page 166

Fuse-To-Components Index Image 6-4

Testing and Inspection

Daytime Running Lamp Control Unit: Testing and Inspection

DAYTIME RUNNING LIGHTS CONTROL UNIT / INPUT TEST

CAUTION:

All SRS wire harnesses are covered with yellow insulation. Before you disconnect any part of an

SRS wire harness, disconnect the airbag connectors.

Whenever the ignition switch is ON, or has been turned OFF for less than three minutes, be careful

not to bump the SRS unit; the airbags could accidentally deploy and cause damage or injuries.

For additional precautions, refer to SRS See: Restraint Systems/Air Bag Systems/Service

Precautions.

1. Remove the dashboard lower cover and knee bolster. 2. Disconnect the connectors from the

daytime running lights control unit.

Page 38

General Module: Diagnostic Aids Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box. 2. Check the battery for damage, state of charge, and

clean and tight connections.

CAUTION: Do not quick-charge a battery unless the battery ground cable has been disconnected, or you will

damage the alternator diodes.

— Do not attempt to crank the engine with the ground cable disconnected or you will severely

damage the wiring.

While You’re Working

1. Make sure connectors are clean, and have no loose terminals or receptacles.

2. Make sure multiple terminal connectors are packed with dielectric (silicone) grease.

Part Number: 08798-9001

3. When connecting a connector, push it until it clicks into place.

CAUTION: Do not pull on the wires when disconnecting a connector. Pull only on the connector housings.

— Most circuits include solid-state devices. Test the voltages in these circuits only with a

10-megaohm or higher impedance digital multimeter. Never use a test light or analog meter on

circuits that contain solid-state devices. Damage to the devices may result.

Page 176

Circuit Identification for In-Line and Fuse Box Connectors Part 2

Locations

82. Front of Driver’s Door

Page 126

3. Inspect the connector and socket terminals to be sure they are all making good contact.

If the terminals are bent, loose or corroded, repair them as necessary, and recheck the system. If

the terminals look OK, make the following input tests at the connector. If any test indicates a problem, find and correct the cause, then recheck the system.

— If all the input tests prove OK, the control unit must be faulty; replace it.

Page 34

Wires

Page 43

General Module: Diagnostic Aids Testing For Continuity

When testing for continuity at a connector without wire seals, you do not have to separate the two

halves of the connector. Instead, probe the connector from the back. Always check both sides of

the connector because dirty, corroded, and bent terminals can cause problems (no electrical

contact = an open).

1. Disconnect the negative cable from the car battery. If you’re using a DVOM, place it in the lowest

«OHMS» range.

2. Connect one lead of a self-powered test light or DVOM to one end of the part of the circuit you

want to test. 3. Connect the other lead to the other end. 4. If the self-powered test light glows, there

is continuity. If you’re using a DVOM, a low reading or no reading (zero), means good continuity.

Page 150

Normally-Open Type 1. Remove the power relay from its socket.

2. Check continuity between relay terminals.

— There should be continuity between the A and C terminals when power and ground are connected

to the B and D terminals.

— There should be no continuity when power is disconnected.

Type 1

Type 1

— Blower Motor Relay

— Rear Window Defogger Relay

Type 2

— Horn Relay

Page 145

— If a test indicates a problem, find and correct the cause, then recheck the system.

— If all the input tests prove OK, the turn signal/hazard relay must be faulty; replace it.

Page 135

Hazard Flasher Relay: Testing and Inspection

TURN SIGNAL & HAZARD RELAY INPUT TEST

CAUTION:

All SRS wire harnesses are covered with yellow insulation. Before you disconnect any part of an

SRS wire harness, disconnect the airbag connectors.

Whenever the ignition switch is ON, or has been turned OFF for less than three minutes, be careful

not to bump the SRS unit; the airbags could accidentally deploy and cause damage or injuries.

For additional precautions, refer to SRS See: Restraint Systems/Air Bag Systems/Service

Precautions.

1. Remove the turn signal/hazard relay from the under-dash fuse/relay box. 2. Inspect the relay and

socket terminals to be sure they are all making good contact.

If the terminals are bent, loose or corroded, repair them as necessary, and recheck the system. If

the terminals look OK, make the following in-put tests at the socket.

Page 108

Compressor Clutch Relay: Testing and Inspection

Relay Test (Normally-Open Type)

Check for continuity between the terminals.

There should be continuity between the A and B terminals when power and ground are connected

to the C and D terminals.

There should be no continuity between the A and S terminals when power is disconnected.

Type 1

— Condenser Fan Relay

— Radiator Fan Relay

— A/C Compressor Clutch Relay

Type 2

Page 51

Engine Oil Pressure Indicator Flasher System

Engine Oil Pressure Indicator Flasher System

Key-in/Seat Belt Reminder System

Key-in/Seat Belt Reminder System

Bulb Check System (brake system light)

Bulb Check System (brake system light)

Locations

64. Behind Dashboard Lower Cover

Page 112

Condenser Fan Motor Relay: Testing and Inspection

RELAY TEST / CONDENSER FAN Normally-Open Type

Type 1

Type 2

Check for continuity between the terminals.

There should be continuity between the A and B terminals when power and ground are connected

to the C and D terminals.

There should be no continuity between the A and S terminals when power is disconnected.

Cavity Numbering System

General Module: Diagram Information and Instructions Cavity Numbering System

Cavity Numbering System

Cavity Numbering System

Page 83

Electronic Brake Control Module: Service and Repair

1. Remove the right quarter trim panel. 2. Disconnect the ABS control unit connectors.

3. Remove the ABS control unit. 4. Install the ABS control unit in the reverse order of removal. 5.

Start the engine, and check that the ABS indicator goes off. 6. Test-drive the vehicle, and check

that the ABS indicator does not come on.

Locations

105. Left Side of Cargo Area (Hatchback)

Page 47

Integrated Control Unit (2 Of 2)

Page 14

Circuit Identification for In-Line and Fuse Box Connectors Part 3

Page 177

Circuit Identification for In-Line and Fuse Box Connectors Part 3

Page 28

Diodes

Page 158

Relay Box: Locations Under-Hood Fuse/Relay Box

Under-Hood Fuse/Relay Box (1 Of 2)

Page 12

General Module: Diagram Information and Instructions Circuit Identification For In-Line and Fuse

Box Connectors

Circuit Identification for In-Line and Fuse Box Connectors Part 1

Five-Step Troubleshooting

General Module: Diagnostic Aids Five-Step Troubleshooting

1. Verify The Complaint

Turn on all the components in the problem circuit to check the accuracy of the customer complaint.

Note the symptoms. Do not begin disassembly or testing until you have narrowed down the

problem area.

2. Analyze The Schematic

Look up the schematic for the problem circuit. Determine how the circuit is supposed to work by

tracing the current paths from the power source through the circuit components to ground. Also,

trace circuits that share wiring with the problem circuit. The names of circuits that share the same

fuse, ground, or switch, and so on, are referred to in each circuit schematic. Try to operate any

shared circuits you didn’t check in step 1. If the shared circuits work, the shared wiring is OK, and

the cause must be in the wiring used only by the problem circuit. If several circuits fail at the same

time, the fuse or ground is a likely cause.

Based on the symptoms and your understanding of the circuit’s operation, identify one or more

possible causes.

3. Isolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made in step 2. Keep in mind that a logical, simple

procedure is the key to efficient troubleshooting. Test for the most likely cause of failure first. Try to

make tests at points that are easily accessible.

4. Fix The Problem

Once the specific problem is identified, make the repair. Be sure to use proper tools and safe

procedures.

5. Make Sure The Circuit Works

Turn on all components in the repaired circuit in all modes to make sure you’ve fixed the entire

problem. If the problem was a blown fuse, be sure to test all of the circuits on that fuse. Make sure

no new problems turn up and the original problem does not recur.

Cavity Numbering System

Body Control Module: Diagram Information and Instructions Cavity Numbering System

Cavity Numbering System

Cavity Numbering System

Page 50

NOTE:

— Different wires with the same color have been given a number suffix to distinguish them (for

example, GRN/BLU1 and GRN/BLU2 are not the same).

— Do not disconnect any connectors on the under-dash fuse/relay box except the integrated control

unit.

All Systems

All Systems

Rear window Defogger Timer System

Rear window Defogger Timer System

Intermittent Wiper Relay System

Intermittent Wiper Relay System

Locations

23. Right Rear Corner of Engine Compartment

Under-Dash Fuse/Relay Box

Relay Box: Application and ID Under-Dash Fuse/Relay Box

Fuse-To-Components View Image 6

Page 98

Cruise Control Module: Testing and Inspection

CRUISE CONTROL UNIT / INPUT TEST

CAUTION:

All SRS wire harnesses are covered with yellow insulation. Before you disconnect any part of an

SRS wire harness, disconnect the airbag connectors.

Whenever the ignition switch is ON, or has been turned OFF for less than three minutes, be careful

not to bump the SRS unit; the airbags could accidentally deploy and cause damage or injuries.

For additional precautions, refer to SRS See: Restraint Systems/Air Bag Systems/Service

Precautions.

1. Remove the dashboard lower cover and knee bolster. 2. Disconnect the 14-P connector from the

control unit.

Locations

22. Right Rear Corner of Engine Compartment

Locations

52. Rear of Dashboard Lower Cover

Page 144

Turn Signal Relay: Testing and Inspection

TURN SIGNAL & HAZARD RELAY INPUT TEST

CAUTION:

All SRS wire harnesses are covered with yellow insulation. Before you disconnect any part of an

SRS wire harness, disconnect the airbag connectors.

Whenever the ignition switch is ON, or has been turned OFF for less than three minutes, be careful

not to bump the SRS unit; the airbags could accidentally deploy and cause damage or injuries.

For additional precautions, refer to SRS See: Restraint Systems/Air Bag Systems/Service

Precautions.

1. Remove the turn signal/hazard relay from the under-dash fuse/relay box. 2. Inspect the relay and

socket terminals to be sure they are all making good contact.

If the terminals are bent, loose or corroded, repair them as necessary, and recheck the system. If

the terminals look OK, make the following in-put tests at the socket.

Page 22

Schematic Symbols

Locations

60. Behind Dashboard Lower Cover

Page 46

General Module: Electrical Diagrams

Integrated Control Unit (1 Of 2)

Locations

22. Right Rear Corner of Engine Compartment

Locations

23. Right Rear Corner of Engine Compartment

Page 13

Circuit Identification for In-Line and Fuse Box Connectors Part 2

Page 30

Ground — G

Page 18

General Module: Diagram Information and Instructions Component Locations

To see where a component or connector is located on the car, look up its photo number in the

Component Location. The photo will also tell you the color of the connector, and how many cavities

it has.

If there is no photo number below or beside a connector, ground, or terminal number, look up that

connector, ground, or terminal number in the appropriate Connector Identification Chart. The chart

will tell you the color of a connector, how many cavities it has, where it’s located, and what

component or harness it connects to. On the page opposite that chart you’ll find an illustration of

the related harness.

Page 41

General Module: Diagnostic Aids Testing For a Short With a Short Circuit Locator (Short Finder)

1. Remove the blown fuse. Leave the battery connected.

2. Connect the short finder across the battery terminals and the load (component) side of the fuse

terminal. 3. Close all switches in the circuit you’re testing. 4. Turn on the short finder. This creates a

pulsing magnetic field around the wiring between the fuse box and the short. 5. Beginning at the

fuse box, slowly move the short finder along the circuit wiring. The meter will show current pulses

through sheet metal and body

trim. As long as the meter is between the fuse and the short, the needle will move with each current

pulse. Once you move the meter past the point of the short, the needle will stop moving. Check the

wiring and connectors in this area to locate the cause of the short.

Page 16

General Module: Diagram Information and Instructions Circuit Schematics

Each schematic represents one circuit. A circuit’s wires and components are arranged to show

current flow, from power at the top of the page, to ground, at the bottom.

Other circuits may share power or ground terminals or wiring with the circuit shown. A wire that

connects one circuit to another, for example, is cut short and has an arrowhead at the end of it

pointing in the direction of current flow. Next to the arrowhead is the name of the circuit or

component which shares that wiring. To quickly check shared wiring, check the operation of a

component it serves. If that component works, you know the shared wiring is OK.

All connectors are numbered (C709, C416, etc.). Below each connector number (except those for

components) is the number of a photo showing the

Page 93

Radiator Cooling Fan Motor Relay: Testing and Inspection Radiator Fan Relay Test

Relays / Test

There should be continuity between the No.1 and No.2 terminals when power and ground are

connected to the No.3 and No.4 terminals, and there should be no continuity when power is

disconnected.

— Condenser Fan Relay

— Radiator Fan Relay

— A/C Compressor Clutch Relay

Page 49

General Module: Testing and Inspection

INTEGRATED CONTROL UNIT / INPUT TEST

CAUTION:

All SRS wire harnesses are covered with yellow insulation. Before you disconnect any part of an

SRS wire harness, disconnect the airbag connectors.

Whenever the ignition switch is ON, or has been turned OFF for less than three minutes, be careful

not to bump the SRS unit; the airbags could accidentally deploy and cause damage or injuries.

For additional precautions, refer to SRS See: Restraint Systems/Air Bag Systems/Service

Precautions.

Remove the dashboard lower cover and knee bolster, then disconnect the 15-P connector from the

integrated control unit.

Remove the integrated control unit from the under-dash fuse/relay box.

Inspect the connector and socket terminals to be sure they are all making good contact.

If the terminals are bent, loose or corroded, repair them as necessary, and recheck the system. If

the terminals look OK, make the following input tests at the connector and under-dash fuse/relay

box. If any test indicates a problem, find and correct the cause, then recheck the system.

— If all the input tests prove OK, the control unit must be faulty; replace it.

Page 60

Reconnect the 14-P connector form the power door lock control unit.

CAUTION: To prevent damage to the motor, apply battery voltage only momentarily

Page 151

— Hatch Release Relay

— Starter Cut Relay

— ABS Pump Motor Relay

— ABS Rear Fail-Safe Relay

Page 59

Power Door Lock Control Module: Testing and Inspection

POWER DOOR LOCKS CONTROL UNIT / INPUT TEST

1. Remove the driver’s door panel. 2. Disconnect the 14-P connector from the control unit.

3 Inspect the connector and socket terminals to be sure they are all making good contact.

If the terminals are bent, loose or corroded, repair them as necessary, and recheck the system. If

the terminals look OK, make the following in-put tests at the connector. If any test indicates a problem, find and correct the cause, then recheck the system.

— If all the input tests prove OK, the control unit must be faulty; replace it.

Disconnect the 14-P connector form the power door lock control unit.

Locations

122. Above Left Kick Panel (Optional)

Locations

7. Right Front of Engine Compartment

Page 33

Switches

Page 157

12. Right Side of Engine Compartment

Locations

100. Behind Right Quarter Panel Trim (Hatchback)

Page 44

General Module: Diagnostic Aids Testing For Voltage

When testing for voltage at a connector without wire seals, you do not have to separate the two

halves of the connector. Instead, probe the connector from the back. Always check both sides of

the connector because dirty, corroded, and bent terminals can cause problems (no electrical

contact an open).

1. Connect one lead of the test light to a known good ground, or, if you’re using a digital volt

ohmmeter (DVOM), place it in the appropriate DC

volts range, and connect its negative lead to ground.

2. Connect the other lead of the test light or DVOM to the point you want to check. 3. If the test light

glows, there is voltage present. If you’re using a DVOM, note the voltage reading. It should be

within one volt of measured battery

voltage. A loss of more than one volt indicates a problem.

NOTE: Always use a DVOM on high impedance circuits. A test light may not glow (even with

battery voltage present).

Honda Integra. Хонда Интегра. DC1. Технические регламенты и рекомендуемые интервалы технического обслуживания.

Моторное масло: Honda 5W30, Honda 10W30. Допускается использование моторного масла с вязкостью 5W40, 10W40. Для замены потребуется 3,4 литра. Упаковка – 4 литра (4 банки). Интервал замены, — 5000-7500 км. Наши рекомендованные интервалы отличаются от интервалов, указанных в мануалах Honda Russia в два раза. Удвоить частоту замены масла мы предлагаем руководствуясь рекомендациями Honda Japan.

Масляный фильтр: вместе с заменой масла.

Топливный фильтр: каждые 30 000 — 40 000 км.

Воздушный фильтр: 15 000 км, или по внешнему состоянию.

Жидкость в КПП:

МКПП – MTF– 2 литра. Интервал замены — 40 000 км.

АКПП — ATF DW-1– от 2,5 до 3,2 литра (в зависимости от положения автомобиля и открытии/закрытии клапанов в момент остановки двигателя). Потребуется покупать до 4-х литров. Интервал замены 40 000 км.

АКПП — ATF Z1– от 2,5 до 3,2 литра (в зависимости от положения автомобиля и открытии/закрытии клапанов в момент остановки двигателя). Потребуется покупать до 4-х литров. Интервал замены 40 000 км.

Жидкость в ГУР: PSF. Для замены потребуется около 1 литра. Ресурс — 50 000 км.

Тормозная жидкость: DOT 3, DOT 4. Замена по интервалу, — 1 раз в 2 года. Для полной замены требуется около 1 литра жидкости.

Охлаждающая жидкость (антифриз): Оригинальная охлаждающая жидкость- 10 лет с момента выпуска автомобиля. Рекомендуемый интервал замены, — 1 раз в 2-3 года. Рекомендуется охлаждающая жидкость не ниже класса G12. Для полной замены потребуется чуть больше 4-х литров жидкости. Для частичной замены, — меньше 4-х.

Свечи зажигания: Ресурс обычной свечи зажигания — 20 000 км. Подбор свечи осуществляется по VIN (Frame)- номеру + комплектация.

Замена ремня (узла) ГРМ:

Подбор осуществляется только по vin- или frame- номеру автомобиля. Комплект для замены ремня ГРМ подразумевает следующие позиции:

Двигатели ZC, оригинальная продукция Honda.

Ремень ГРМ (ресурс 100 000 км)

Ролик-натяжитель ремня ГРМ (ресурс 100 000 км)

Сальник лобовины коленвала (ресурс 100 000 км)

Сальник распредвала (ресурс 100 000 км)

Прокладка клапанной крышки (ресурс определяется мастером)

Кольца свечных колодцев (ресурс определяется мастером)

Отдельно рассматривается вопрос о замене помпы (насоса охлаждающей жидкости), ресурс которой составляет 200 000 км.

- Совет!

При замене ремня ГРМ на двигателях ZC вместе с помпой, допустимо использовать вместе с оригинальным комплектом ремня ГРМ дубликатную помпу, чей реальный ресурс составляет 100 000 км. В данном случае общий ресурс узла станет одинаковым. Старайтесь всегда использовать оригинальные сальники, это существенно повысит ресурс узла в целом.

- Совет!

Старайтесь избегать использования неоригинальной продукции в узле ГРМ. В случае, если Вы понимаете риск использования неоригинальной продукции и готовы установить его в свой автомобиль, ориентируйтесь на вдвое меньший ресурс узла, даже если использован только один элемент комплекта ремня ГРМ.

Замена тормозных колодок:

Передние тормозные колодки: в зависимости от производителя и стиля езды, замена передних тормозных колодок осуществляется каждые 25 000 – 60 000 км.

Задние тормозные колодки: ресурс барабанных колодок может достигать 200 000 км. Дисковые колодки рекомендуются к замене каждые 40 000 км. Номер по Nisshinbo — 8266

Регулировка клапанов. Регламент регулировки клапанов, — 40 000 км пробега. Для проведения операции потребуются прокладки клапанной крышки и кольца свечных колодцев.

Если вы нашли ошибку, пожалуйста, выделите фрагмент текста и нажмите Ctrl+Enter.

Еще интересные статьи

Руководство на английском языке по ремонту и техническому обслуживанию Acura Integra 1986-1989 г.

- Автор: —

- Издательство: Honda Motor Co., Ltd.

- Год издания: 1986

- Страниц: 682

- Формат: PDF

- Размер: 156,8 Мб

Руководство на английском языке по ремонту и техническому обслуживанию Acura Integra 1990-1993 г.

- Автор: —

- Издательство: Honda Motor Co., Ltd.

- Год издания: —

- Страниц: 1163

- Формат: PDF

- Размер: 55,5 Мб

Руководство на английском языке по ремонту и техническому обслуживанию Acura Integra 1994-1997 г.

- Автор: —

- Издательство: Honda Motor Co., Ltd.

- Год издания: 1993

- Страниц: 1413

- Формат: PDF

- Размер: 33,5 Мб

Руководство на английском языке по ремонту и техническому обслуживанию Acura Integra 1998-2001 г.

- Автор: —

- Издательство: Honda Motor Co., Ltd.

- Год издания: 1997

- Страниц: 1681

- Формат: PDF

- Размер: 49,1 Мб

Мультимедийное руководство по обслуживанию и ремонту Acura Integra и Honda Civic с 1994 года выпуска.

- Автор: —

- Издательство: —

- Год издания: —

- Страниц: —

- Формат: multimedia

- Размер: 218,8 Мб

Service Manual Acura Integra Mark III (DB7/DB8/DC2/DC4 — North American market) с бензиновыми двигателями: B18B1 1.8 л (1834 см³) 141 л.с./104 кВт и B18C1 1.8 л (1797 см³) 170 л.с./125 кВт. Профессиональное руководство по ремонту и техническому обслуживанию для СТО легковой автомобиль малого среднего класса (компактный) Акура Интегра с цельнометаллическими несущими кузовами трехдверный хэтчбек и четырёхдверный седан переднеприводные модели для Северной Америки третьего поколения выпуска с 1993 по 2001 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео Акура Интегра замена распределителя зажигания и генератора (Acura Integra 94)

Акура Интегра 1993-2001 общая информация (Acura Integra DB7/DB8/DC2/DC4)

В оригинальном руководстве по ремонту «Honda Motor Co., LTD», на английском языке, дается подробное описание технологических процедур по демонтажу, сборки, диагностики, ремонту отдельных узлов и техническому обслуживанию автомобилей Acura Integra и его модификаций 1994 год выпуска.

Состоит из следующих глав:

- Раздел Основная информация

- Раздел Специальный инструмент

- Раздел Спецификация

- Раздел Настройки и обслуживание

- Раздел Двигатель

- Раздел Система охлаждения

- Раздел Системы впуска и выпуска

- Раздел Трансмиссия

- Раздел Рулевое управление

- Раздел Подвеска

- Раздел Тормозная система (Включая систему «ABS»)

- Раздел Кузов и салон

- Раздел Системы отопления и кондиционирования

- Раздел Электрические схемы и электрооборудование (Включая систему «SRS»)

Конструкция системы тормозов

Диагонально распределенный, двойной контур системы тормозов позволяет в случае отказа одного контура тормозов нормально выполнять функции торможения другому контуру. Для того, чтобы остановить автомобиль в случае, если из одной половины тормозной системы полностью вытечет тормозная жидкость, потребуется дополнительное давление на педаль тормоза (ход педали увеличится по сравнению с нормальным положением).

Кроме того, использование половины тормозной мощности приведет к увеличению тормозного пути. Если неожиданно отказали тормоза, необходимо перейти на пониженную передачу и как можно скорее съехать на обочину.

• Опасно ездить на автомобиле, если в электрической или гидравлической системе тормозов имеются неполадки. В таком случае необходимо немедленно обратиться к дилеру «Хонда».

• Не ставьте ногу на педаль тормоза, если вы не собираетесь тормозить. Это приводит к преждевременному износу тормозов, может повредить их или отрицательно сказаться на эффективности торможения. Кроме того, включение стоп-сигналов на вашем автомобиле введет в заблуждение водителей, едущих за вами.

• Езда по глубокой воде может отразиться на работе тормозов. Мягко нажмите на педаль, чтобы проверить эффективность действия тормозов. Если автомобиль не снижает скорости, как обычно, продолжайте мягко наступать на педаль, двигаясь на безопасной скорости, пока тормоза не высохнут и не вернутся в нормальное рабочее состояние. Износ тормозов Передние и задние тормоза должны регулярно проверяться в соответствии с графиком проведения техобслуживания. Когда детали тормозной системы нуждаются в замене, пользуйтесь только фирменными запасными деталями «Хонда» или их аналогами.

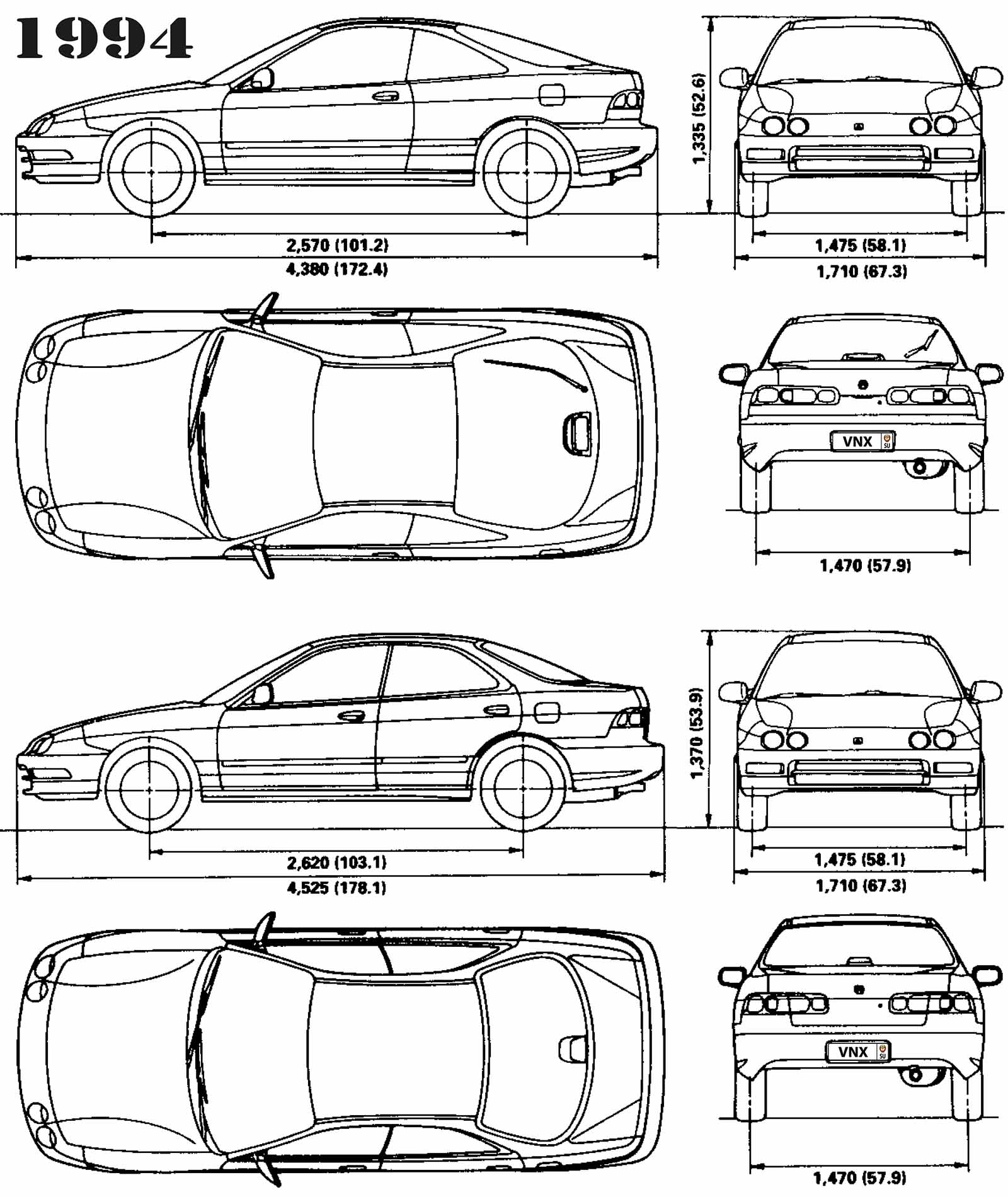

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 4380 |

| 2 | Ширина (без/с зеркалами) / Width | 1710 |

| 3 | Высота (загружен/пустой) / Height | 1335 |

| 4 | Колёсная база / Wheelbase | 2570 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 150 |

| 6 | Снаряжённая масса / Total (curb) weight | 1197 |

| Полная масса / Gross (max.) weight | 1670 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Бензиновый, жидкостного охлаждения, четырехтактный, B18B1 |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 4-цилиндровый, рядный, 16V, DOHC с верхним расположением двух распредвалов |

| 9 | Диаметр цилиндра / Bore | 81.0 мм |

| 10 | Ход поршня / Stroke | 89.0 мм |

| 11 | Объём / Engine displacement | 1834 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Распределенный впрыск топлива PGM-FI |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 9.2:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 104 кВт (144 л.с.) при 6300 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 169 Нм при 5200 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | Однодисковое, сухое, с диафрагменной нажимной пружиной и гасителем крутильных колебаний, постоянно замкнутого типа |

| 17 | КПП / Transmission type | Y80 МКПП 5 пятиступенчатая механическая, двухвальная, с синхронизаторами на всех передачах переднего хода |

О Книге

- Название: Acura Integra 1994 Service Manual

- Бензиновые двигатели: B18B1 1.8 л (1834 см³) 141 л.с./104 кВт и B18C1 1.8 л (1797 см³) 170 л.с./125 кВт

- Выпуск с 1994 года

- Серия: «Workshop Manual»

- Год издания: июль 1993

- Автор: Коллектив авторов

- Издательство: «Honda Motor Co., Ltd»

- Формат: PDF

- Страниц в книге: 1413

- Размер: 32.86 МБ

- Язык: Английский — Graecum est, non legitur

- Количество электросхем: более 50