Новости

Самые популярные статьи

-

Принтеры и МФУ -

-

Epson с СНПЧ и ПЗК -

Прошитый Samsung -

Принтер и МФУ HP -

Oki принтеры и мфу -

Ручной принтер -

Прошитый МФУ, принтер Pantum

-

-

СНПЧ -

-

СНПЧ Epson -

СНПЧ Canon -

СНПЧ Hp -

СНПЧ Brother -

СНПЧ Конструктор ( комплектующие )

-

-

Принтеры в разборе -

-

Epson струйные и лазерные принтеры и мфу -

HP струйные и лазерные принтеры и мфу -

Canon струйные и лазерные принтеры и мфу -

Samsung лазерные принтеры и мфу -

Brother струйные и лазерные принтеры и мфу -

OKI струйные и лазерные принтеры и МФУ -

Panasonic лазерные принтеры и мфу -

Xerox лазерные принтеры и МФУ -

Sharp лазерные принтеры и МФУ -

Ricoh лазерные принтеры и МФУ -

Kyocera лазерные принтеры и МФУ

-

-

ПЗК -

-

ПЗК Epson -

ПЗК HP -

ПЗК Canon -

ПЗК Brother

-

-

Чернила -

-

Чернила Epson -

Чернила Canon -

Чернила HP -

Чернила Brother -

Чернила Epson, Canon, HP в канистре

-

-

Фотобумага -

-

Фотобумага глянцевая -

Фотобумага матовая -

Фотобумага фактурная. Дизайнерская -

Рулонная фотобумага -

Фотобумага мелованная (2-х сторонний глянец для струйной печати) -

Оригинальная фотобумага HP, Canon, Epson

-

-

Термобумага для терминалов и банкоматов -

Тонер -

-

Тонер HP -

Тонер Samsung -

Тонер Canon -

Тонер Epson -

Тонер Xerox -

Тонер Brother -

Тонер Panasonic -

Тонер Kyocera -

Тонер OKI -

Тонер Ricoh -

Тонер Toshiba -

Тонер Konica -

Тонер Sharp -

Тонер Handan -

Тонер Lexmark

-

-

Лазерные картриджи -

-

Картридж Epson -

Картридж Canon -

Картридж HP -

Картридж Samsung -

Картридж Xerox -

Картридж Brother -

Картридж Panasonic -

Картридж Kyocera -

Картридж OKI -

Картридж Toshiba, Sharp, Lexmark, Ricoh

-

-

ЗИП для картриджа -

-

ЗИП картриджа Canon -

ЗИП картриджа HP -

ЗИП картриджа Samsung -

ЗИП картриджа Xerox -

ЗИП картриджа Brother -

ЗИП картриджа Panasonic -

ЗИП картриджа Lexmark -

ЗИП картриджа Ricoh, Kyocera, Sharp -

Пакеты для картриджей

-

-

Комплектующие (ЗИП) для принтера -

-

ЗИП Epson -

-

Print Head ( Печатающая головка ) -

Pump Assy ( Узел подачи чернил в сборе ) -

Board Assy ( Электронная плата ) -

DAMPER ( Демпер ) -

Cable Assy ( Шлейф в сборе ) -

Belt, Scale ( ремень каретки, лента позиционирования ) -

Motor Assy ( двигатель ) -

Paper feed unit ( узел подачи бумаги ) -

Gear ( Шестерня ) -

Scaner unit ( блок сканера ) -

Power Assy ( блок питания ) -

Разное Epson

-

-

ЗИП Canon -

-

Печатающая головка Canon -

Электронная плата Canon -

Узел термозакрепления Canon -

Узел подачи бумаги Canon -

Ремни, ленты позиционирования, диски энкодера Canon -

Шлейфы Canon -

Узел подачи чернил Canon -

Шестеренки Canon -

Блоки питания Canon -

Электродвигатели и соленоиды Canon -

Датчики Canon -

Разное Canon

-

-

ЗИП HP -

-

Печатающая головка HP -

Электронная плата HP -

Узел термозакрепления HP -

Узел подачи бумаги HP -

Ремни, ленты позиционирования, диски энкодера HP -

Шлейфы HP -

Узел подачи чернил HP -

Модули памяти HP -

Шестеренки HP -

Подшипники (бушинги) HP -

Блоки питания HP -

Электродвигатели и соленоиды HP -

Узел сканирования HP -

Датчики HP -

Разное HP

-

-

ЗИП Samsung -

-

Электронная плата Samsung -

Узел термозакрепления Samsung -

Узел подачи бумаги Samsung -

Шлейфы Samsung -

Шестеренки Samsung -

Подшипники (бушинги) Samsung -

Блоки питания Samsung -

Электродвигатели и соленоиды Samsung -

Узел сканирования Samsung -

Блок лазера Samsung -

Датчики Samsung -

Разное Samsung. Товары, не вошедшие в предыдущие категории

-

-

ЗИП Xerox -

-

Печатающая головка Xerox -

Электронная плата Xerox -

Узел термозакрепления Xerox -

Узел подачи бумаги Xerox -

Ремни, ленты позиционирования, диски энкодера Xerox -

Шлейфы Xerox -

Узел подачи чернил Xerox -

Шестеренки Xerox -

Электродвигатели и соленоиды Xerox -

Блоки питания Xerox -

Узел сканирования Xerox -

Датчики Xerox -

Блок лазера Xerox -

Разное Xerox

-

-

ЗИП Brother -

-

Печатающая головка Brother -

Электронная плата Brother -

Узел термозакрепления Brother -

Узел подачи бумаги Brother -

Ремни, ленты позиционирования, диски энкодера Brother -

Шлейфы Brother -

Узел подачи чернил Brother -

Шестеренки Brother -

Блоки питания Brother -

Электродвигатели и соленоиды Brother -

Датчики Brother -

Узел сканирования Brother -

Блок лазера Brother -

Разное Brother

-

-

ЗИП Kyocera -

-

Электронная плата Kyocera -

Узел термозакрепления Kyocera -

Узел подачи бумаги Kyocera -

Шлейфы Kyocera -

Шестеренки Kyocera -

Подшипники (бушинги) Kyocera -

Блоки питания Kyocera -

Электродвигатели и соленоиды Kyocera -

Узел сканирования Kyocera -

Блок лазера Kyocera -

Датчики Kyocera -

Разное Kyocera. Товары, не вошедшие в предыдущие категории

-

-

ЗИП Panasonic, OKI, Ricoh, Pantum -

-

Печатающая головка Panasonic, Oki, Ricoh, Pantum -

Электронная плата Panasonic, Oki, Ricoh, Pantum -

Узел термозакрепления Panasonic, Oki, Ricoh, Pantum -

Узел подачи бумаги Panasonic, Oki, Ricoh, Pantum -

Ремни, ленты позиционирования, диски энкодера Panasonic, Oki, Ricoh, Pantum -

Шлейфы Panasonic, Oki, Ricoh, Pantum -

Узел подачи чернил Panasonic, Oki, Ricoh, Pantum -

Шестеренки Panasonic, Oki, Ricoh, Pantum -

Блоки питания Panasonic, Oki, Ricoh, Pantum -

Электродвигатели и соленоиды Panasonic, Oki, Ricoh, Pantum -

Датчики Panasonic, Oki, Ricoh, Pantum -

Узел сканирования Panasonic, Oki, Ricoh, Pantum -

Блок лазера Panasonic, Oki, Ricoh, Pantum -

Разное Panasonic, Oki, Ricoh, Pantum

-

-

ЗИП Lexmark, Toshiba, Sharp -

-

Печатающая головка Lexmark, Toshiba, Sharp -

Электронная плата Lexmark, Toshiba, Sharp -

Узел термозакрепления Lexmark, Toshiba, Sharp -

Узел подачи бумаги Lexmark, Toshiba, Sharp -

Ремни, ленты позиционирования, диски энкодера Lexmark, Toshiba, Sharp -

Шлейфы Lexmark, Toshiba, Sharp -

Узел подачи чернил Lexmark, Toshiba, Sharp -

Шестеренки Lexmark, Toshiba, Sharp -

Блоки питания Lexmark, Toshiba, Sharp -

Электродвигатели и соленоиды Lexmark, Toshiba, Sharp -

Узел сканирования Lexmark, Toshiba, Sharp -

Блок лазера Lexmark, Toshiba, Sharp -

Датчики Lexmark, Toshiba, Sharp -

Разное Lexmark, Toshiba, Sharp

-

-

ЗИП Термопринтера -

Стекла для МФУ и сканера

-

-

Струйные картриджи -

-

Картриджи Epson -

Картриджи Canon -

Картриджи HP -

Картриджи Brother, Lexmark, Sharp

-

-

Чипы -

-

Чипы Epson -

Чипы Canon -

Чипы HP -

Чипы Samsung -

Чипы Xerox -

Чипы OKI -

Чипы Ricoh -

Чипы Pantum -

Чипы Kyocera -

Чипы Lexmark

-

-

Решение для принтера -

-

Прошивка Epson -

Генераторы, Прошивки Samsung -

Генераторы, Прошивки Xerox -

Прошитая оригиналом память -

Прошивка принтера Pantum -

Прошивки и Сервисные программы Canon

-

-

Химия для техники -

-

Промывочная жидкость -

Смазки и масла для техники -

Восстанавливающие, очищающие средства

-

-

Программаторы -

Радиодетали -

-

Транзисторы -

Микросхемы памяти FLASH -

Микросхемы памяти EEPROM -

Микроконтроллеры -

Конденсаторы -

Блок питания

-

-

Материалы для наружной рекламы -

Сублимация -

3D печать ABS PLA -

Планшетный принтер, текстильная печать -

Разработка сайтов и программного обеспечения -

Для ноутбука -

-

Зарядные устройства -

Аккумуляторы

-

-

Запчасти для телевизоров и мониторов -

-

Электронные платы для телевизоров -

Матрицы для телевизора -

Блоки питания для телевизоров -

Тюнеры для телевизора -

Светодиодная подсветка -

Шлейфы и кабели для телевизоров и мониторов -

Разное для телевизоров и мониторов

-

-

Запчасти для асиков (asic miner)

Вход

Самое покупаемое

-

-

Repair manuals

-

Printers

-

Kyocera

-

ECOSYS FS-1025MFP

-

Drivers

2

-

Repair manuals

6

-

User manuals

6

Kyocera ECOSYS FS-1025MFP installation instructions

(22 pages)

- Languages:English

-

Type:

PDF -

Size:

557.63 KB -

Description:

IB-51 WEB Browser Management Setup Guide

WEB Browser Management Guide

Preview

Kyocera ECOSYS FS-1025MFP installation instructions

(2 pages)

- Languages:English

-

Type:

PDF -

Size:

384.72 KB -

Description:

IB-50 Setup Guide

Setup Guide for the IB-50

Preview

Kyocera ECOSYS FS-1025MFP installation instructions

(38 pages)

- Languages:English

-

Type:

PDF -

Size:

3.32 MB -

Description:

Mac Driver Setup Guide Rev 4.2.018.06

Cover Installation and Setup of the Mac Driver

Preview

Kyocera ECOSYS FS-1025MFP installation instructions

(66 pages)

- Languages:English

-

Type:

PDF -

Size:

866.8 KB -

Description:

KYOmulticode 1.0/PCL Barcode Flash 3.0 Quick Install Guide

Quick Installation Guide

Preview

Kyocera ECOSYS FS-1025MFP service manual

(118 pages)

- Languages:English

-

Type:

PDF -

Size:

659.95 KB -

Description:

Kyocera Command Center RX User Guide Rev-9.2016.6

User Guide for Kyocera Command Center RX

Preview

Kyocera ECOSYS FS-1025MFP service manual

(218 pages)

- Languages:English

-

Type:

PDF -

Size:

14.36 MB

Preview

Kyocera ECOSYS FS-1025MFP (Printers) service manuals in PDF format will help to find failures and errors and repair Kyocera ECOSYS FS-1025MFP and restore the device’s functionality.

ECOSYS FS-1020MFP ECOSYS FS-1220MFP ECOSYS FS-1120MFP ECOSYS FS-1320MFP ECOSYS FS-1025MFP ECOSYS FS-1125MFP ECOSYS FS-1325MFP

SERVICE

MANUAL

Published in March 2013

842M7111

2M7SM0611

Rev.1

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

It may be illegal to dispose of this battery into the municipal waste stream. Check with your local solid waste officials for details in your area for proper disposal.

ATTENTION

IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE DE TYPE INCORRECT. METTRE AU REBUT LES BATTERIES UTILISEES SELON LES INSTRUCTIONS DONNEES.

Il peut être illégal de jeter les batteries dans des eaux d’égout municipales. Vérifiez avec les fonctionnaires municipaux de votre région pour les détails concernant des déchets solides et une mise au rebut appropriée.

Notation of products in the manual

For the purpose of this service manual, products are identified by print speed at A4/Letter modes.

Ecosys FS-1020MFP: 3 in1 model by 20/21 ppm (without FAX and document processor) Ecosys FS-1220MFP:3 in1 model by 20/21 ppm (without FAX and document processor) Ecosys FS-1120MFP: 4 in1 model by 20/21 ppm (with FAX)

Ecosys FS-1320MFP:4 in1 model by 20/21 ppm (with FAX) Ecosys FS-1025MFP: 3 in1 model by 25/26 ppm (without FAX) Ecosys FS-1125MFP: 4 in1 model by 25/26 ppm (with FAX) Ecosys FS-1325MFP:4 in1 model by 25/26 ppm (with FAX)

Revision history

|

Revision |

Date |

Replaced pages |

Remarks |

|

1 |

March 29, 2013 |

Contents, 1-1-4,1-1-9,1-2-6 to1-2-9,1-3-3, |

— |

|

1-3-4,1-3-7,1-3-11,1-3-15 to 1-3-20,1-4-1 to 1-4-3, |

|||

|

1-4-6 to1-4-8,1-4-10 to 1-4-15,1-4-18,1-4-22,1-4-25, |

|||

|

1-5-22,1-5-25,1-5-30,1-5-31,1-6-1 to 1-6-6, |

|||

|

2-1-1,2-1-6,,2-1-13,2-1-15,2-2-4,2-2-5,2-3-4,2-3-5, |

|||

|

2-3-11,2-3-17,2-4-17,2-4-18,2-4-21,2-4-22 |

|||

This page is intentionally left blank.

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of their customers, their machines as well as themselves during maintenance activities. Service personnel are advised to read this booklet carefully to familiarize themselves with the warnings and precautions described here before engaging in maintenance activities.

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and to prevent damage to their property. These symbols are described below:

Symbols

The triangle (

|

General warning. |

Warning of risk of electric shock. |

Warning of high temperature.

|

General prohibited action. |

Disassembly prohibited. |

|

General action required. |

Remove the power plug from the wall outlet. |

Always ground the copier.

1. Installation Precautions

•Do not use a power supply with a voltage other than that specified. Avoid multiple connections to one outlet: they may cause fire or electric shock. When using an extension cable, always check that it is adequate for the rated current…………………………………………………………………………………………

•Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or electric shock. Connecting the earth wire to an object not approved for the purpose may cause explosion or electric shock. Never connect the ground cable to any of the following: gas pipes, lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the proper authorities………………………………………………………………………………………………………………………….

•Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury……….

•Do not install the copier in a humid or dusty place. This may cause fire or electric shock………………

•Do not install the copier near a radiator, heater, other heat source or near flammable material. This may cause fire……………………………………………………………………………………………………………………

•Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool as possible. Insufficient ventilation may cause heat buildup and poor copying performance. …………

•Always handle the machine by the correct locations when moving it. ………………………………………….

•Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause the copier to move unexpectedly or topple, leading to injury. ……………………………………………………..

•Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical atten-

tion. …………………………………………………………………………………………………………………………………..

•Advice customers that they must always follow the safety warnings and precautions in the copier’s instruction handbook. ………………………………………………………………………………………………………….

2. Precautions for Maintenance

•Always remove the power plug from the wall outlet before starting machine disassembly. …………….

•Always follow the procedures for maintenance described in the service manual and other related brochures. …………………………………………………………………………………………………………………………

•Under no circumstances attempt to bypass or disable safety features including safety mechanisms and protective circuits. …………………………………………………………………………………………………………

•Always use parts having the correct specifications. ………………………………………………………………….

•Always use the thermostat or thermal fuse specified in the service manual or other related brochure when replacing them. Using a piece of wire, for example, could lead to fire or other serious accident. …………………………………………………………………………………………………………………………………

•When the service manual or other serious brochure specifies a distance or gap for installation of a part, always use the correct scale and measure carefully. …………………………………………………………

•Always check that the copier is correctly connected to an outlet with a ground connection. ……………

•Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it is dirty, clean it to remove the risk of fire or electric shock. ………………………………………………………..

•Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may damage eyesight. ……………………………………………………………………………………………………………….

•Handle the charger sections with care. They are charged to high potentials and may cause electric shock if handled improperly. …………………………………………………………………………………………………

•Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are safely secured so they will not be caught in rotating sections. …………………………………………………………….

•Use utmost caution when working on a powered machine. Keep away from chains and belts. ……….

•Handle the fixing section with care to avoid burns as it can be extremely hot. …………………………….

•Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause abnormally high temperatures. ……………………………………………………………………………………………..

•Do not remove the ozone filter, if any, from the copier except for routine replacement. ………………….

•Do not pull on the AC power cord or connector wires on high-voltage components when removing them; always hold the plug itself. …………………………………………………………………………………………..

•Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a cable cover or other appropriate item. ……………………………………………………………………………………

•Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ……….

•Remove toner completely from electronic components. ……………………………………………………………

•Run wire harnesses carefully so that wires will not be trapped or damaged. ………………………………..

•After maintenance, always check that all the parts, screws, connectors and wires that were removed, have been refitted correctly. Special attention should be paid to any forgotten connector, trapped wire and missing screws. ………………………………………………………………………………………….

•Check that all the caution labels that should be present on the machine according to the instruction handbook are clean and not peeling. Replace with new ones if necessary. …………………………………

•Handle greases and solvents with care by following the instructions below: ………………………………..

·Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

·Ventilate the room well while using grease or solvents.

·Allow applied solvents to evaporate completely before refitting the covers or turning the power switch on.

·Always wash hands afterwards.

•Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to fire in a furnace, etc. ……………………………………………………………………………………………………………

•Should smoke be seen coming from the copier, remove the power plug from the wall outlet immediately. …………………………………………………………………………………………………………………………………

3. Miscellaneous

•Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the specified refiner; it may generate toxic gas. …………………………………………………………………………….

•Keep the machine away from flammable liquids, gases, and aerosols. A fire or an electric shock might occur. ……………………………………………………………………………………………………………………….

This page is intentionally left blank.

|

2M4/2M5/2M6/2M7 |

||

CONTENTS |

||

|

1-1 Specifications |

||

|

1-1-1 Specifications ………………………………………………………………………………………………………… |

1-1-1 |

|

|

1-1-2 Parts names ………………………………………………………………………………………………………… |

1-1-10 |

|

|

(1) |

Machine ………………………………………………………………………………………………………….. |

1-1-10 |

|

(2) |

Operation panel ……………………………………………………………………………………………….. |

1-1-12 |

|

1-1-3 Machine cross section …………………………………………………………………………………………… |

1-1-13 |

|

|

(1) |

20/21 ppm Model……………………………………………………………………………………………… |

1-1-13 |

|

(2) |

25/26 ppm Model……………………………………………………………………………………………… |

1-1-14 |

|

(3) |

ISU/DP Section………………………………………………………………………………………………… |

1-1-15 |

|

1-2 Installation |

||

|

1-2-1 Installation environment…………………………………………………………………………………………… |

1-2-1 |

|

|

1-2-2 Unpacking and installation……………………………………………………………………………………….. |

1-2-3 |

|

|

(1) |

Installation procedure …………………………………………………………………………………………. |

1-2-3 |

|

1-3 Service Mode |

||

|

1-3-1 Service mode…………………………………………………………………………………………………………. |

1-3-1 |

|

|

(1) |

Executing a Service mode…………………………………………………………………………………… |

1-3-1 |

|

(2) |

Operation Method………………………………………………………………………………………………. |

1-3-2 |

|

1-3-2 Maintenance menu ……………………………………………………………………………………………….. |

1-3-19 |

|

|

(1) |

Items for various settings…………………………………………………………………………………… |

1-3-21 |

|

(2) |

Service package ………………………………………………………………………………………………. |

1-3-23 |

|

1-4 Troubleshooting |

||

|

1-4-1 Paper misfeed detection………………………………………………………………………………………….. |

1-4-1 |

|

|

(1) |

Paper misfeed indication …………………………………………………………………………………….. |

1-4-1 |

|

(2) |

Paper misfeed detection condition ……………………………………………………………………….. |

1-4-2 |

|

1-4-2 Self-diagnostic function …………………………………………………………………………………………… |

1-4-5 |

|

|

(1) |

Self-diagnostic function ………………………………………………………………………………………. |

1-4-5 |

|

(2) |

Self diagnostic codes………………………………………………………………………………………….. |

1-4-6 |

|

1-4-3 Image formation problems……………………………………………………………………………………… |

1-4-10 |

|

|

(1) |

No image appears (entirely white)………………………………………………………………………. |

1-4-11 |

|

(2) |

No image appears (entirely black)………………………………………………………………………. |

1-4-11 |

|

(3) |

Part of image is missing. …………………………………………………………………………………… |

1-4-12 |

|

(4) |

Gray background. …………………………………………………………………………………………….. |

1-4-12 |

|

(5) |

White streaks are printed vertically……………………………………………………………………… |

1-4-13 |

|

(6) |

Black streaks are printed vertically. …………………………………………………………………….. |

1-4-13 |

|

(7) |

White or black streaks are printed horizontally……………………………………………………… |

1-4-13 |

|

(8) |

Spots are printed.Printing incomplete or out of position …………………………………………. |

1-4-14 |

|

(9) |

Printing incomplete or out of position ………………………………………………………………….. |

1-4-14 |

|

(10) |

Paper is wrinkled. …………………………………………………………………………………………….. |

1-4-14 |

|

(11) |

Offset occurs. ………………………………………………………………………………………………….. |

1-4-15 |

|

(12) |

Fusing is loose…………………………………………………………………………………………………. |

1-4-15 |

|

(13) |

Faint or blurred printing …………………………………………………………………………………….. |

1-4-15 |

|

(14) |

Dirt on the top edge or back of the paper. ……………………………………………………………. |

1-4-16 |

|

(15) |

Image center does not align with the original center. …………………………………………….. |

1-4-16 |

|

(16) |

Unevenly repeating horizontal streaks in the printed objects. |

|

|

Spots in the printed objects ………………………………………………………………………………. |

1-4-16 |

|

|

1-4-4 Electric problems ………………………………………………………………………………………………….. |

1-4-17 |

|

2M4/2M5/2M6/2M7-1 |

|||

|

1-4-5 |

Mechanical problems…………………………………………………………………………………………….. |

1-4-20 |

|

|

1-4-6 |

Error Messages ……………………………………………………………………………………………………. |

1-4-22 |

|

|

1-4-7 |

Send error list ………………………………………………………………………………………………………. |

1-4-27 |

|

|

1-4-8 |

Error codes ………………………………………………………………………………………………………….. |

1-4-28 |

|

|

(1) Error code……………………………………………………………………………………………………….. |

1-4-28 |

||

|

(2) Table of general classification ……………………………………………………………………………. |

1-4-29 |

||

|

(2-1) |

U004XX error code table: Interrupted phase B …………………………………………….. |

1-4-32 |

|

|

(2-2) |

U006XX error code table: Problems with the unit …………………………………………. |

1-4-33 |

|

|

(2-3) |

U008XX error code table: Page transmission error……………………………………….. |

1-4-33 |

|

|

(2-4) |

U009XX error code table: Page reception error ……………………………………………. |

1-4-33 |

|

|

(2-5) |

U010XX error code table: G3 transmission………………………………………………….. |

1-4-34 |

|

|

(2-6) |

U011XX error code table: G3 reception ………………………………………………………. |

1-4-36 |

|

|

(2-7) |

U017XX error code table: V.34 transmission ……………………………………………….. |

1-4-37 |

|

|

(2-8) |

U018XX error code table: V.34 reception…………………………………………………….. |

1-4-38 |

|

|

(2-9) |

U023XX error code table: Relay command abnormal reception ……………………… |

1-4-38 |

|

|

(2-10) |

U044XX error code table: Encrypted transmission ……………………………………….. |

1-4-38 |

1-5 Assembly and disassembly

|

1-5-1 Precautions for assembly and disassembly………………………………………………………………… |

1-5-1 |

|

|

(1) |

Precautions……………………………………………………………………………………………………….. |

1-5-1 |

|

(2) |

Drum………………………………………………………………………………………………………………… |

1-5-1 |

|

(3) |

Toner ……………………………………………………………………………………………………………….. |

1-5-1 |

|

(4) |

How to tell a genuine Kyocera toner container……………………………………………………….. |

1-5-2 |

|

1-5-2 Outer covers ………………………………………………………………………………………………………….. |

1-5-3 |

|

|

(1) |

Detaching and refitting the right upper cover and Rear upper cover R ………………………. |

1-5-3 |

|

(2) |

Detaching and refitting the Left upper cover and Rear upper cover L………………………… |

1-5-4 |

|

(3) |

Detaching and refitting the Right cover …………………………………………………………………. |

1-5-5 |

|

(4) |

Detaching and refitting the Left cover……………………………………………………………………. |

1-5-6 |

|

(5) |

Detaching and refitting the Top cover……………………………………………………………………. |

1-5-7 |

|

1-5-3 Optical section ……………………………………………………………………………………………………… |

1-5-10 |

|

|

(1) |

Detaching and refitting the scanner unit ………………………………………………………………. |

1-5-10 |

|

(2) |

Detaching and refitting the laser scanner unit ………………………………………………………. |

1-5-15 |

|

1-5-4 Fuser section ……………………………………………………………………………………………………….. |

1-5-17 |

|

|

(1) |

Detaching and refitting the fuser unit…………………………………………………………………… |

1-5-17 |

|

1-5-5 PWBs………………………………………………………………………………………………………………….. |

1-5-18 |

|

|

(1) |

Detaching and refitting the main PWB…………………………………………………………………. |

1-5-18 |

|

(2) |

Detaching and refitting the high voltage PWB, power source PWB and |

|

|

FAX PWB (4 in 1 model only)…………………………………………………………………………….. |

1-5-21 |

|

|

1-5-6 Document processor (4 in 1 20/21,25/26 ppm model, 3 in 1 25/26 ppm model only) ……… |

1-5-25 |

|

|

(1) |

Detaching and refitting the Document processor ………………………………………………….. |

1-5-25 |

|

(2) |

Detaching and refitting the DP forward roller and DP paper feed roller ……………………. |

1-5-27 |

|

(3) |

Detaching and refitting the DP Separation pad …………………………………………………….. |

1-5-29 |

|

1-5-7 Others…………………………………………………………………………………………………………………. |

1-5-30 |

|

|

(1) |

Detaching and refitting the Main motor unit………………………………………………………….. |

1-5-30 |

|

(2) |

Direction of installing the principal fan motor………………………………………………………… |

1-5-36 |

1-6 Requirements on PWB Replacement

|

1-6-1 |

Upgrading the firmware …………………………………………………………………………………………… |

1-6-1 |

|

1-6-2 |

Remarks on main PWB replacement…………………………………………………………………………. |

1-6-6 |

|

2M4/2M5/2M6/2M7 |

||

|

2-1 Mechanical Construction |

||

|

2-1-1 Paper feed/ conveying section …………………………………………………………………………………. |

2-1-1 |

|

|

(1) |

Cassette paper feed/ paper conveying section ………………………………………………………. |

2-1-1 |

|

(2) |

Manual feed section (25/26 ppm model only)…………………………………………………………. |

2-1-2 |

|

2-1-2 Drum section …………………………………………………………………………………………………………. |

2-1-4 |

|

|

2-1-3 Developer section…………………………………………………………………………………………………… |

2-1-5 |

|

|

2-1-4 Optical section ……………………………………………………………………………………………………….. |

2-1-6 |

|

|

(1) |

Scanner unit ……………………………………………………………………………………………………… |

2-1-6 |

|

(2) |

Laser scanner section ………………………………………………………………………………………… |

2-1-7 |

|

2-1-5 Transfer/Separation section …………………………………………………………………………………… |

2-1-10 |

|

|

2-1-6 Fuser section ……………………………………………………………………………………………………….. |

2-1-11 |

|

|

2-1-7 Duplex conveying/Eject section………………………………………………………………………………. |

2-1-13 |

|

|

2-1-8 Document processor (DP) ……………………………………………………………………………………… |

2-1-15 |

|

|

2-2 Electrical Parts Layout |

||

|

2-2-1 Electrical parts layout ……………………………………………………………………………………………… |

2-2-1 |

|

|

(1) |

PWBs……………………………………………………………………………………………………………….. |

2-2-1 |

|

(2) |

Switches and sensors…………………………………………………………………………………………. |

2-2-3 |

|

(3) |

Others………………………………………………………………………………………………………………. |

2-2-4 |

|

(4) |

Document processor (3 in 1 25/26 ppm model, 4 in 1 20/21, 25/26 ppm model)…………. |

2-2-5 |

|

2-3 Operation of the PWBs |

||

|

2-3-1 Main PWB……………………………………………………………………………………………………………… |

2-3-1 |

|

|

(1) |

3 in 1 25/26 ppm model, 4 in 1 20/21, 25/26 ppm model …………………………………………. |

2-3-1 |

|

(2) |

3 in 1 20/21 ppm model ………………………………………………………………………………………. |

2-3-8 |

|

2-3-2 Relay PWB PWB ………………………………………………………………………………………………….. |

2-3-12 |

|

|

2-3-3 Power source PWB ………………………………………………………………………………………………. |

2-3-14 |

|

|

2-3-4 FAX control PWB………………………………………………………………………………………………….. |

2-3-16 |

|

|

2-3-5 Operation panel PWB……………………………………………………………………………………………. |

2-3-18 |

|

|

2-4 Appendixes |

||

|

2-4-1 Maintenance kits…………………………………………………………………………………………………….. |

2-4-1 |

|

|

(1) |

Maintenance kits………………………………………………………………………………………………… |

2-4-1 |

|

2-4-2 Procedure for replacing Maintenance kit ……………………………………………………………………. |

2-4-2 |

|

|

(1) |

Checking the components included and |

|

|

preparing the paper-feed replacement unit for installation ……………………………………….. |

2-4-2 |

|

|

(2) |

Preparing the machine ……………………………………………………………………………………….. |

2-4-4 |

|

(3) |

Detaching the Drum unit……………………………………………………………………………………… |

2-4-6 |

|

(4) |

Detaching the developer unit……………………………………………………………………………….. |

2-4-7 |

|

(5) |

Detaching the toner disposal box …………………………………………………………………………. |

2-4-7 |

|

(6) |

Detaching and refitting the paper feed pulley and lower paper feed guide …………………. |

2-4-8 |

|

(7) |

Refitting the toner disposal box ………………………………………………………………………….. |

2-4-12 |

|

(8) |

Refitting the developer unit………………………………………………………………………………… |

2-4-12 |

|

(9) |

Refitting the drum unit ………………………………………………………………………………………. |

2-4-13 |

|

(10) |

Detaching and refitting the transfer roller …………………………………………………………….. |

2-4-14 |

|

(11) |

Notice after replacing maintenance kit ………………………………………………………………… |

2-4-15 |

|

(12) |

Procedure for only replacing Drum unit ……………………………………………………………….. |

2-4-17 |

|

(13) |

Procedure for only replacing Developer unit ………………………………………………………… |

2-4-18 |

|

2-4-3 Cleaning the Machine……………………………………………………………………………………………. |

2-4-20 |

|

|

(1) |

Interior of the Machine………………………………………………………………………………………. |

2-4-20 |

|

(2) |

Slit Glass Cover……………………………………………………………………………………………….. |

2-4-21 |

|

2M4/2M5/2M6/2M7 |

||

|

2-4-4 Appendixes………………………………………………………………………………………………………….. |

2-4-22 |

|

|

(1) |

Repetitive defects gauge …………………………………………………………………………………… |

2-4-22 |

|

(2) |

Wiring diagram ………………………………………………………………………………………………… |

2-4-23 |

2M4/2M5/2M6/2M7

1-1-1 Specifications

Machine

Specifications |

||||||

|

Item |

3 in 1 model (without FAX) |

4 in 1 model (with FAX) |

||||

|

20/21 ppm |

25/26 ppm |

20/21 ppm |

25/26 ppm |

|||

|

Type |

Desktop |

|||||

|

Printing method |

Electrophotography by semiconductor laser |

|||||

|

Support Original types |

Sheet, Book, 3-dimensional objects (maximum original size: A4/Letter) |

|||||

|

Original feed system |

Fixed |

|||||

|

Cassette |

60 to 220 g/m2 (Duplex: 60 to 120 g/m2) |

|||||

|

Paper weight |

||||||

|

Manual feed |

— |

60 to 220 g/m2 |

— |

60 to 220 g/m2 |

||

|

tray* |

||||||

|

Cassette/ |

Plain, Preprinted, Labels, Bond, Recycled, Vellum, Rough, Letterhead, |

|||||

|

Paper type |

Manual feed |

Color, Prepunched, Envelope, Cardstock, Thick paper, High Quality, Cus- |

||||

|

tray* |

tom 1 to 8 |

|||||

|

A4, JIS/ISO B5, A5, Folio, Legal, Letter, Oficio II (215.9 × 330.2 mm, 8-1/2 |

||||||

|

× 13 inches), Mexican Oficio (216 × 340 mm), Statement, Executive, A6, |

||||||

|

Cassette |

Envelope Monarch, Envelope #10, Envelope #9, Envelope #6-3/4, Enve- |

|||||

|

lope C5, Envelope DL, 16K, Custom (70 × 148 to 216 × 356 mm 2-3/4 × 5- |

||||||

|

13/16 to 8-1/2 × 14 inches) |

||||||

|

— |

A4, JIS/ISO B5, |

— |

A4, JIS/ISO B5, |

|||

|

A5, Folio, Legal, |

A5, Folio, Legal, |

|||||

|

Letter, Oficio II |

Letter, Oficio II |

|||||

|

(215.9 × 330.2 |

(215.9 × 330.2 |

|||||

|

mm, 8-1/2 × 13 |

mm, 8-1/2 × 13 |

|||||

|

inches), Mexi- |

inches), Mexi- |

|||||

|

can Oficio (216 × |

can Oficio (216 × |

|||||

|

Paper size |

340 mm), State- |

340 mm), State- |

||||

|

ment, Executive, |

ment, Executive, |

|||||

|

Manual feed |

A6, Envelope |

A6, Envelope |

||||

|

Monarch, Enve- |

Monarch, Enve- |

|||||

|

tray* |

||||||

|

lope #10, Enve- |

lope #10, Enve- |

|||||

|

lope #9, |

lope #9, |

|||||

|

Envelope #6-3/4, |

Envelope #6-3/4, |

|||||

|

Envelope C5, |

Envelope C5, |

|||||

|

Envelope DL, |

Envelope DL, |

|||||

|

16K, Custom (70 |

16K, Custom (70 |

|||||

|

× 148 to 216 × |

× 148 to 216 × |

|||||

|

356 mm 2-3/4 × |

356 mm 2-3/4 × |

|||||

|

5-13/16 to 8-1/2 |

5-13/16 to 8-1/2 |

|||||

|

× 14 inches) |

× 14 inches) |

|||||

|

25 to 400%, 1% increments |

||||||

|

Zoom level |

||||||

1-1-1

|

2M4/2M5/2M6/2M7 |

||||||

|

Specifications |

||||||

|

Item |

3 in 1 model (without FAX) |

4 in 1 model (with FAX) |

||||

|

20/21 ppm |

25/26 ppm |

20/21 ppm |

25/26 ppm |

|||

|

Light |

63 g/m² or less |

|||||

|

Paper weight |

Normal 1 |

64 to 69 g/m² |

||||

|

Normal 2(3) |

70 to 105 g/m² |

|||||

|

setting |

||||||

|

Heavy 1 |

106 to 135 g/m² |

|||||

|

Heavy 2(3) |

136 to 220 g/m² |

|||||

|

When using the DP |

||||||

|

— |

Light: 18 |

Light: 18 |

Light: 18 |

|||

|

A4 |

Normal 1: 18 |

Normal 1: 18 |

Normal 1: 18 |

|||

|

Normal 2(3): 18 |

Normal 2(3): 18 |

Normal 2(3): 18 |

||||

|

— |

Light: 18 |

Light: 15 |

Light: 18 |

|||

|

A4(Quiet |

Normal 1: 18 |

Normal 1: 15 |

Normal 1: 18 |

|||

|

Normal 2(3): 18 |

Normal 2(3): 15 |

Normal 2(3): 18 |

||||

|

Mode) |

||||||

|

Heavy 1: 17 |

Heavy 1: 14 |

Heavy 1: 17 |

||||

|

Heavy 2(3): 16 |

Heavy 2(3): 13 |

Heavy 2(3): 16 |

||||

|

— |

Light: 21 |

Light: 21 |

Light: 21 |

|||

|

Letter |

Normal 1: 21 |

Normal 1: 21 |

Normal 1: 21 |

|||

|

Normal 2(3): 21 |

Normal 2(3): 21 |

Normal 2(3): 21 |

||||

|

— |

Light: 19 |

Light: 16 |

Light: 19 |

|||

|

Copying |

Letter(Quiet |

Normal 1: 19 |

Normal 1: 16 |

Normal 1: 19 |

||

|

Normal 2(3): 19 |

Normal 2(3): 16 |

Normal 2(3): 19 |

||||

|

speed |

Mode) |

|||||

|

Heavy 1: 17 |

Heavy 1: 14 |

Heavy 1: 17 |

||||

|

(feed from |

||||||

|

Heavy 2(3): 16 |

Heavy 2(3): 13 |

Heavy 2(3): 16 |

||||

|

cassette) |

||||||

|

( images/ |

— |

Light: 16 |

Light: 13 |

Light: 16 |

||

|

min) |

Legal |

Normal 1: 16 |

Normal 1: 13 |

Normal 1: 16 |

||

|

(300 × 300 |

Normal 2(3): 16 |

Normal 2(3): 13 |

Normal 2(3): 16 |

|||

|

dpi |

||||||

|

— |

Light: 15 |

Light: 12 |

Light: 15 |

|||

|

Legal(Quiet |

Normal 1: 15 |

Normal 1: 12 |

Normal 1: 15 |

|||

|

Normal 2(3): 15 |

Normal 2(3): 12 |

Normal 2(3): 15 |

||||

|

Mode) |

||||||

|

Heavy 1: 13 |

Heavy 1: 11 |

Heavy 1: 13 |

||||

|

Heavy 2(3): 11 |

Heavy 2(3): 10 |

Heavy 2(3): 11 |

||||

|

— |

Light: 15 |

Light: 12 |

Light: 15 |

|||

|

A5/B5/A6 |

Normal 1: 15 |

Normal 1: 12 |

Normal 1: 15 |

|||

|

Normal 2(3): 15 |

Normal 2(3): 12 |

Normal 2(3): 15 |

||||

|

(Quiet Mode) |

||||||

|

Heavy 1: 13 |

Heavy 1: 10 |

Heavy 1: 13 |

||||

|

Heavy 2(3): 12 |

Heavy 2(3): 9 |

Heavy 2(3): 12 |

||||

|

A5/B5/ |

— |

Light: 12 |

Light: 10 |

Light: 12 |

||

|

A6(from 11th |

Normal 1: 12 |

Normal 1: 10 |

Normal 1: 12 |

|||

|

image) |

Normal 2(3): 12 |

Normal 2(3): 10 |

Normal 2(3): 12 |

|||

|

(Quiet Mode) |

Heavy 1: 11 |

Heavy 1: 8 |

Heavy 1: 11 |

|||

|

Heavy 2(3): 10 |

Heavy 2(3): 8 |

Heavy 2(3): 10 |

||||

1-1-2

|

2M4/2M5/2M6/2M7 |

||||||

|

Specifications |

||||||

|

Item |

3 in 1 model (without FAX) |

4 in 1 model (with FAX) |

||||

|

20/21 ppm |

25/26 ppm |

20/21 ppm |

25/26 ppm |

|||

|

When the DP is not used |

||||||

|

Light: 20 |

Light: 25 |

Light: 20 |

Light: 25 |

|||

|

A4 |

Normal 1: 20 |

Normal 1: 25 |

Normal 1: 20 |

Normal 1: 25 |

||

|

Normal 2(3): 20 |

Normal 2(3): 25 |

Normal 2(3): 20 |

Normal 2(3): 25 |

|||

|

Light: 15 |

Light: 18 |

Light: 15 |

Light: 18 |

|||

|

A4(Quiet |

Normal 1: 15 |

Normal 1: 18 |

Normal 1: 15 |

Normal 1: 18 |

||

|

Normal 2(3): 15 |

Normal 2(3): 18 |

Normal 2(3): 15 |

Normal 2(3): 18 |

|||

|

Mode) |

||||||

|

Heavy 1: 14 |

Heavy 1: 17 |

Heavy 1: 14 |

Heavy 1: 17 |

|||

|

Heavy 2(3): 13 |

Heavy 2(3): 16 |

Heavy 2(3): 13 |

Heavy 2(3): 16 |

|||

|

Copying |

Light: 21 |

Light: 26 |

Light: 21 |

Light: 26 |

||

|

Letter |

Normal 1: 21 |

Normal 1: 26 |

Normal 1: 21 |

Normal 1: 26 |

||

|

speed |

||||||

|

Normal 2(3): 21 |

Normal 2(3): 26 |

Normal 2(3): 21 |

Normal 2(3): 26 |

|||

|

(feed from |

||||||

|

cassette) |

Light: 16 |

Light: 19 |

Light: 16 |

Light: 19 |

||

|

( images/ |

Letter(Quiet |

Normal 1: 16 |

Normal 1: 19 |

Normal 1: 16 |

Normal 1: 19 |

|

|

min) |

Normal 2(3): 16 |

Normal 2(3): 19 |

Normal 2(3): 16 |

Normal 2(3): 19 |

||

|

(300 × 300 |

Mode) |

Heavy 1: 14 |

Heavy 1: 17 |

Heavy 1: 14 |

Heavy 1: 17 |

|

|

dpi) |

Heavy 2(3): 13 |

Heavy 2(3): 16 |

Heavy 2(3): 13 |

Heavy 2(3): 16 |

||

|

Light: 12 |

Light: 15 |

Light: 12 |

Light: 15 |

|||

|

A5/B5/A6 |

Normal 1: 12 |

Normal 1: 15 |

Normal 1: 12 |

Normal 1: 15 |

||

|

Normal 2(3): 12 |

Normal 2(3): 15 |

Normal 2(3): 12 |

Normal 2(3): 15 |

|||

|

(Quiet Mode) |

||||||

|

Heavy 1: 10 |

Heavy 1: 13 |

Heavy 1: 10 |

Heavy 1: 13 |

|||

|

Heavy 2(3): 9 |

Heavy 2(3): 12 |

Heavy 2(3): 9 |

Heavy 2(3): 12 |

|||

|

A5/B5/ |

Light: 10 |

Light: 12 |

Light: 10 |

Light: 12 |

||

|

A6(from 11th |

Normal 1: 10 |

Normal 1: 12 |

Normal 1: 10 |

Normal 1: 12 |

||

|

image) |

Normal 2(3): 10 |

Normal 2(3): 12 |

Normal 2(3): 10 |

Normal 2(3): 12 |

||

|

(Quiet Mode) |

Heavy 1: 8 |

Heavy 1: 11 |

Heavy 1: 8 |

Heavy 1: 11 |

||

|

Heavy 2(3): 8 |

Heavy 2(3): 10 |

Heavy 2(3): 8 |

Heavy 2(3): 10 |

|||

|

First copy |

When using |

— |

13 seconds or |

14 seconds or |

13 seconds or |

|

|

time |

the DP |

less |

less |

less |

||

|

(A4, feed from |

When the DP |

12 seconds or |

11 seconds or |

12 seconds or |

11 seconds or |

|

|

cassette) |

is not used |

less |

less |

less |

less |

|

|

Warm-up |

Power on |

20 seconds or |

23 seconds or |

28 seconds or |

28 seconds or |

|

|

less |

less |

less |

less |

|||

|

time |

||||||

|

(22 °C/71.6 |

Sleep |

12 seconds or |

14 seconds or |

12 seconds or |

14 seconds or |

|

|

°F, 60% RH) |

less |

less |

less |

less |

||

|

Paper |

Cassette |

250 sheets (80 g/m2) |

||||

|

Manual feed |

— |

1 sheet |

— |

1 sheet |

||

|

capacity |

||||||

|

tray* |

||||||

|

Standard |

100 sheets (80 g/m2) |

|||||

|

Output tray |

paper |

(The machine pauses after 100 sheets are printed.) |

||||

|

capacity |

Special |

— |

1 sheet |

— |

1 sheet |

|

|

paper |

||||||

|

Continuous copying |

1 to 99 sheets |

|||||

1-1-3

|

2M4/2M5/2M6/2M7-1 |

||||||

|

Specifications |

||||||

|

Item |

3 in 1 model (without FAX) |

4 in 1 model (with FAX) |

||||

|

20/21 ppm |

25/26 ppm |

20/21 ppm |

25/26 ppm |

|||

|

Photoconductor |

OPC drum (drum diameter 24 mm) |

|||||

|

Image write system |

Semiconductor laser (1 beam) |

|||||

|

Charging system |

Charger roller |

|||||

|

Developing system |

Mono component dry developing method |

|||||

|

Toner replenishing: Automatic from the toner container |

||||||

|

Transfer system |

Transfer roller |

|||||

|

Separation system |

Small diameter separation, discharger brush |

|||||

|

Cleaning system |

Counter blade |

|||||

|

Charge erasing system |

Exposure by eraser lamp (LED) |

|||||

|

Fusing system |

Heat roller system |

|||||

|

Abnormally high temperature protection devices: thermostat |

||||||

|

CPU |

ARM926EJ 390MHz |

|||||

|

Memory |

ROM:32MB/ RAM:64 MB(Maxmum 64 MB) |

|||||

|

USB Interface |

USB Interface |

USB Interface |

USB Interface |

|||

|

connector: 1 |

connector: 1 |

connector: 1 |

connector: 1 |

|||

|

(USB Hi-Speed) |

(USB Hi-Speed) |

(USB Hi-Speed) |

(USB Hi-Speed) |

|||

|

Network inter- |

Public telephone |

Network inter- |

||||

|

Interface |

face: 1 (10 |

line: 1 |

face: 1 (10 |

|||

|

BASE-T/100 |

BASE-T/100 |

|||||

|

BASE-TX) |

BASE-TX) |

|||||

|

Public telephone |

||||||

|

line: 1 |

||||||

|

Resolution |

600 × 600 dpi |

|||||

|

Temperature |

10 to 32.5 °C/ 50 to 90.5 °F |

|||||

|

Humidity |

15 to 80% RH |

|||||

|

Operating |

3,500 m/11,482.8 ft or less |

|||||

|

Altitude |

High altitude mode is available for regular operation at less than 1500m or |

|||||

|

environment |

1500 – 3500m. |

|||||

|

Brightness |

1,500 lux or less |

|||||

|

390 × 333 × 317 |

390 × 361 × 362 mm |

|||||

|

Dimensions |

machine |

mm |

15 3/8 × 14 3/16 × 14 1/4″ |

|||

|

(W × D × H) |

only |

15 3/8 × 13 1/8 × |

||||

|

12 1/2″ |

||||||

|

390 × 645 mm |

424 × 630 mm |

424 × 645 mm |

424 × 630 mm |

|||

|

(using paper |

(using paper |

(using paper |

(using paper |

|||

|

Space required (W × D) |

feed tray) |

feed tray) |

feed tray) |

feed tray) |

||

|

15 3/8 × 25 3/8″ |

16 11/16 × 24 13/ |

16 11/16 × 25 3/ |

16 11/16 × 24 |

|||

|

16″ |

8″ |

13/16″ |

||||

1-1-4

|

2M4/2M5/2M6/2M7 |

||||||

|

Specifications |

||||||

|

Item |

3 in 1 model (without FAX) |

4 in 1 model (with FAX) |

||||

|

20/21 ppm |

25/26 ppm |

20/21 ppm |

25/26 ppm |

|||

|

Weight |

8.7 kg/19.18 lb |

10.0 kg/22 lb |

9.7 kg/21.34 lb |

10.1 kg/22.22 lb |

||

|

Power source |

120 |

V Specification Model:120 V (60 Hz, 6.0 A) |

||||

|

230 |

V Specification Model: 220 to 240 V (50 Hz/60 Hz, 3.1 A) |

|||||

*:The Manual Feed tray is only provided on the 25/26 ppm model. NOTE: These specifications are subject to change without notice.

1-1-5

|

2M4/2M5/2M6/2M7 |

||||||

|

Printer |

||||||

|

Item |

Specifications |

|||||

|

20/21ppm |

25/26ppm |

|||||

|

Light |

63 g/m² or less |

|||||

|

Normal 1 |

64 to 69 g/m² |

|||||

|

Paper weight |

Normal |

70 to 105 g/m² |

||||

|

2(3) |

||||||

|

setting |

||||||

|

Heavy 1 |

106 to 135 g/m² |

|||||

|

Heavy |

136 to 220 g/m² |

|||||

|

2(3) |

||||||

|

Light: 20 |

Light: 25 |

|||||

|

A4 |

Normal 1: 20 |

Normal 1: 25 |

||||

|

Normal 2(3): 20 |

Normal 2(3): 25 |

|||||

|

Light: 15 |

Light: 18 |

|||||

|

A4(Quiet |

Normal 1: 15 |

Normal 1: 18 |

||||

|

Normal 2(3): 15 |

Normal 2(3): 18 |

|||||

|

Mode) |

||||||

|

Heavy 1: 14 |

Heavy 1: 17 |

|||||

|

Heavy 2(3): 13 |

Heavy 2(3): 16 |

|||||

|

Light: 21 |

Light: 26 |

|||||

|

Letter |

Normal 1: 21 |

Normal 1: 26 |

||||

|

Normal 2(3): 21 |

Normal 2(3): 26 |

|||||

|

Light: 16 |

Light: 19 |

|||||

|

Let- |

Normal 1: 16 |

Normal 1: 19 |

||||

|

ter(Quiet |

Normal 2(3): 16 |

Normal 2(3): 19 |

||||

|

Mode) |

Heavy 1: 14 |

Heavy 1: 17 |

||||

|

Printing |

Heavy 2(3): 13 |

Heavy 2(3): 16 |

||||

|

speed |

Light: 13 |

Light: 20 |

||||

|

Simplex |

Legal |

Normal 1: 13 |

Normal 1: 20 |

|||

|

(images/min) |

Normal 2(3): 13 |

Normal 2(3): 20 |

||||

|

Light: 12 |

Light: 15 |

|||||

|

Legal(Qui |

Normal 1: 12 |

Normal 1: 15 |

||||

|

Normal 2(3): 12 |

Normal 2(3): 15 |

|||||

|

et Mode) |

Heavy 1: 11 |

Heavy 1: 13 |

||||

|

Heavy 2(3): 10 |

Heavy 2(3): 11 |

|||||

|

Light: 12 |

Light: 15 |

|||||

|

A5/B5/A6 |

Normal 1: 12 |

Normal 1: 15 |

||||

|

(Quiet |

Normal 2(3): 12 |

Normal 2(3): 15 |

||||

|

Mode) |

Heavy 1: 10 |

Heavy 1: 13 |

||||

|

Heavy 2(3): 9 |

Heavy 2(3): 12 |

|||||

|

A5/B5/ |

Light: 10 |

Light: 12 |

||||

|

A6(from |

Normal 1: 10 |

Normal 1: 12 |

||||

|

11th |

Normal 2(3): 10 |

Normal 2(3): 12 |

||||

|

image) |

Heavy 1: 8 |

Heavy 1: 11 |

||||

|

(Quiet |

Heavy 2(3): 8 |

Heavy 2(3): 10 |

||||

|

Mode) |

||||||

1-1-6

|

2M4/2M5/2M6/2M7 |

||||||

|

Item |

Specifications |

|||||

|

20/21ppm |

25/26ppm |

|||||

|

— |

Light: 15 |

|||||

|

A4 |

Normal 1: 15 |

|||||

|

Normal 2(3): 15 |

||||||

|

— |

Light: 11 |

|||||

|

A4(Quiet |

Normal 1: 11 |

|||||

|

Normal 2(3): 11 |

||||||

|

Mode) |

||||||

|

Heavy 1: 11 |

||||||

|

Heavy 2(3): 11 |

||||||

|

— |

Light: 15 |

|||||

|

Letter |

Normal 1: 15 |

|||||

|

Printing |

Normal 2(3): 15 |

|||||

|

speed |

— |

Light: 11 |

||||

|

Duplex |

Letter |

Normal 1: 11 |

||||

|

(images/min) |

(Quiet |

Normal 2(3): 11 |

||||

|

Mode) |

Heavy 1: 11 |

|||||

|

Heavy 2(3): 11 |

||||||

|

— |

Light: 13 |

|||||

|

Legal |

Normal 1: 13 |

|||||

|

Normal 2(3): 13 |

||||||

|

— |

Light: 10 |

|||||

|

Legal(Qui |

Normal 1: 10 |

|||||

|

Normal 2(3): 10 |

||||||

|

et Mode) |

||||||

|

Heavy 1: 9 |

||||||

|

Heavy 2(3): 9 |

||||||

|

First print time |

8.5 seconds or less |

7.5 seconds or less |

||||

|

(A4, feed from cassette) |

||||||

|

Resolution |

Fast 1200 dpi |

|||||

|

600 × 600 dpi |

||||||

|

Operating system |

Windows XP, Windows Server 2003/R2, Windows Vista , Windows 7 , |

|||||

|

Windows Server 2008/R2, Mac OS X 10.5 or higher |

||||||

* : Duplex printing is only possible on the 25/26 ppm model.

1-1-7

2M4/2M5/2M6/2M7

Scanner

|

Item |

Specifications |

|||

|

System Requirements |

CPU: 20 MHz |

|||

|

RAM: 64 MB |

||||

|

Resolution |

600 × 600 dpi, 400 × 400 dpi, 300 × 300 dpi, 200 × 200 dpi |

|||

|

File format |

BMP,JPG,PNG, TIFF, PDF, |

|||

|

Scanning |

300 dpi |

B/W : 18 images/min |

||

|

speed |

Color: 6 images/min |

|||

|

Simplex |

||||

|

B/W : 5 images/min |

||||

|

(A4 land- |

600 dpi |

|||

|

Color: 1 images/min |

||||

|

scape) |

||||

|

PC transmission: Scan to Folder |

||||

|

Transmission system |

TWAIN scan *1 |

|||

|

WIA scan *2 |

*1 Available operating system: Windows XP, Windows Server 2003/R2, Windows Vista, Windows Server 2008/R2, Windows 7

*2 Available operating system: Windows Vista, Windows Server 2008/R2, Windows 7

Document processor (Standard model only)

|

Item |

Specifications |

|

|

Original feed method |

Automatic feed |

|

|

Supported original types |

Sheet originals |

|

|

Original sizes |

Maximum: Folio/ Legal |

|

|

Minimum : A6/ Statement-R |

||

|

Original weights |

60 to 105 g/m2 |

|

|

Loading capacity |

40 sheets (60 to 80 g/m2) or less |

1-1-8

2M4/2M5/2M6/2M7-1

FAX (4 in 1 model only)

|

Item |

Specifications |

|||

|

Cassette |

A4,Folio,Letter,Legal |

|||

|

Paper size |

Manual Feed |

A4,Folio,Letter,Legal |

||

|

Tray (25/26 |

||||

|

ppm model) |

||||

|

Compatibility |

Super G3 |

|||

|

Communication line |

Subscriber telephone line |

|||

|

Transmission time |

4 seconds or less (33600 bps, MMR, ITU-T A4 #1 chart) |

|||

|

Transmission speed |

33600/31200/28800/26400/24000/21600/19200/16800/14400/12000/9600/ |

|||

|

7200/4800/2400 bps |

||||

|

Coding scheme |

MMR/MR/MH |

|||

|

Error correction |

ECM |

|||

|

Original size |

Max. width:216 mm/8-1/2″,Max. length: 356 mm/14″ |

|||

|

Horizontal × Vertical |

||||

|

Scanner resolution |

Normal 200 × 100 dpi (8 dot/mm × 3.85 line/mm) |

|||

|

Fine 200 × 200 dpi (8 dot/mm × 7.7 line/mm) |

||||

|

Super fine 200 × 400 dpi (8 dot/mm × 15.4 line/mm) |

||||

|

Printing resolution |

600 × 600 dpi |

|||

|

Gradations |

256 shades (Error diffusion) |

|||

|

Multi-Station transmission |

Max. 100 destinations |

|||

|

Substitute |

150 sheets or more (when using ITU-T A4 #1 chart) |

|||

|

memory reception |

||||

|

Report output |

Outgoing FAX Report, Incoming FAX Report,FAX TX result report, |

|||

|

FAX RX result report, Status page, Network status page |

||||

1-1-9

2M4/2M5/2M6/2M7

1-1-2 Parts names

(1) Machine

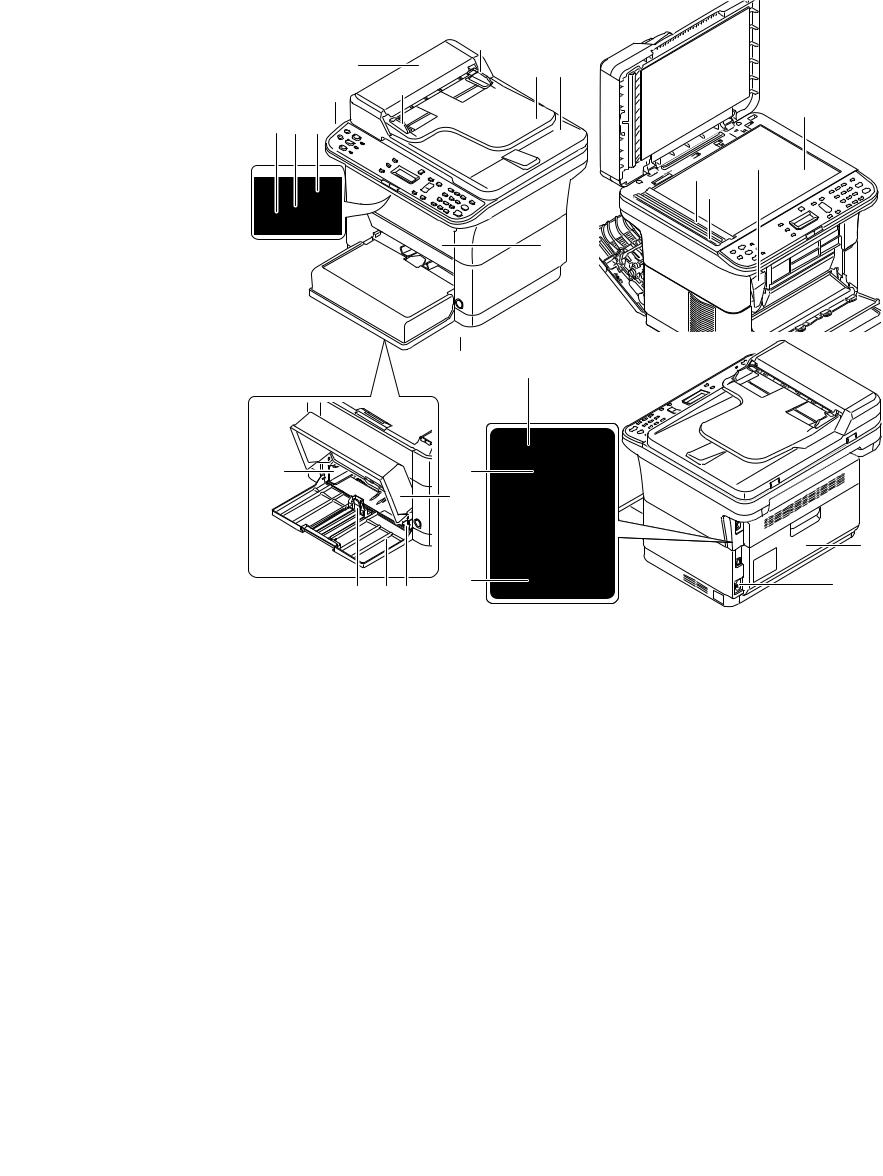

3 in 1 25/26 ppm model, 4 in 1 20/21, 25/26 ppm model

19

4 19

22

3 2 1

8

5

14

13

|

12 |

10 |

11 |

17 |

16 |

|||

|

Figure 1-1-1 |

|||||||

|

1. |

Top tray |

9. |

Cassette cover |

17. |

Line connector*2 |

||

|

2. |

Sub tray |

10. |

Cassette |

18. |

DP top cover |

||

|

3. |

Paper stopper |

11. |

Paper width guides |

19. |

Original width guides |

||

|

4. |

Operation panel |

12. |

Paper length guide |

20. |

Original table |

||

|

5. |

Power switch |

13. |

Rear cover |

21. |

Original eject table |

||

|

6. |

Front cover |

14. |

USB interface connector |

22. |

Platen (contact glass) |

||

|

7. |

Manual feed paper width |

15. |

Network interface connec- |

23. |

Original size Indicator plate |

||

|

guides*1 |

tor*1 |

24. |

Slit glass cover |

||||

|

8. |

Manual feed tray*1 |

16. |

Power code connector |

25. |

Toner container |

||

|

*1: 25/26 ppm model only. |

*2: 4 in 1 model only |

1-1-10

2M4/2M5/2M6/2M7

3 in 1 20/21 ppm model

26

4

2 3

13

16

Figure 1-1-2

26. Original Cover

1-1-11

2M4/2M5/2M6/2M7

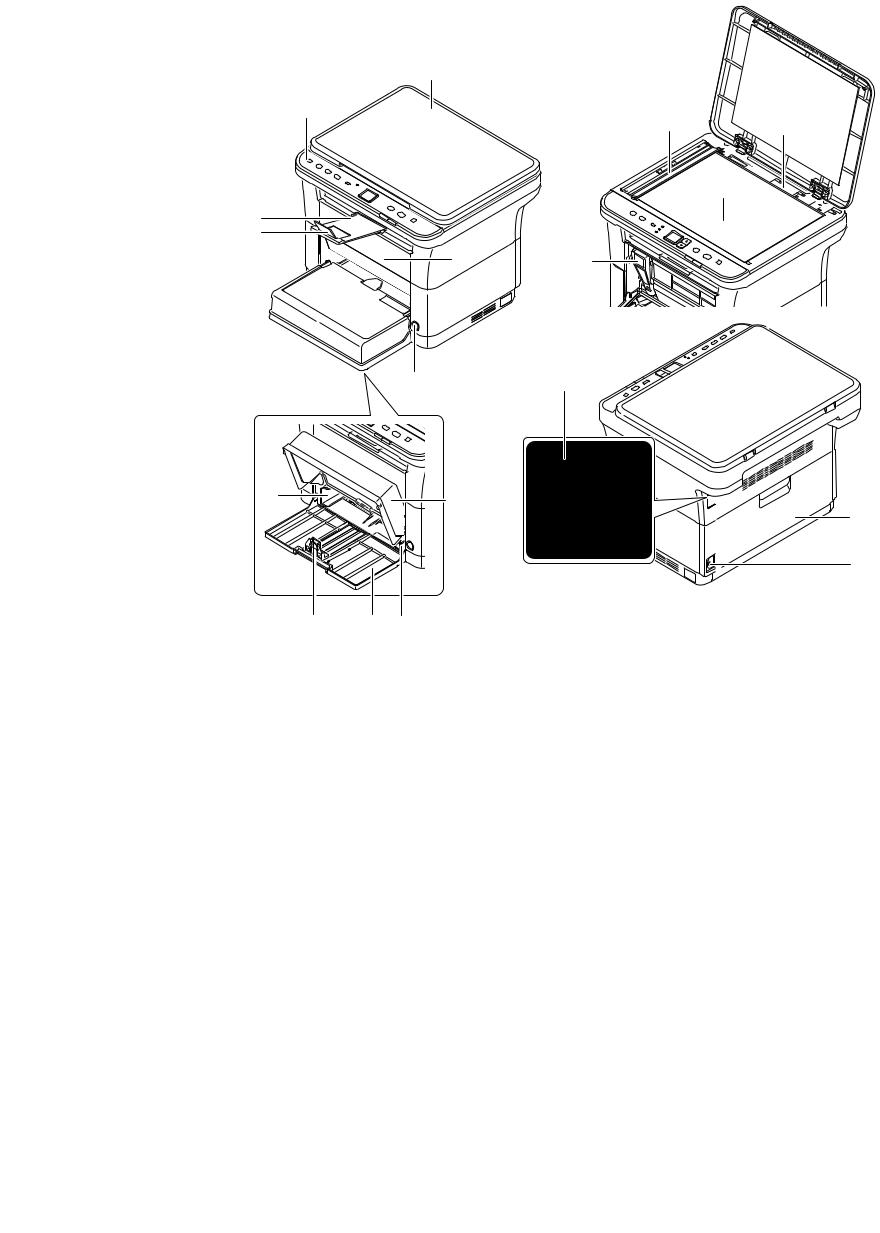

(2) Operation panel

3 in 1 20/21 ppm model

|

1 |

2 |

3 |

4 |

5 |

7 |

10 |

11 |

12 |

|

|

Figure 1-1-3 |

|||||||||

|

1. |

ID Card Copy key |

7. |

Cursor key (Up/Down) |

||||||

|

2. |

Copy key |

8. |

Stop / Reset key |

||||||

|

3. |

Scan key |

9. |

Start key |

||||||

|

4. |

Print Box key |

10. |

Processing indicator |

||||||

|

5. |

Mode select key |

11. |

Attention indicator |

||||||

|

6. |

Message display |

12. |

Quiet Mode key |

3 in 1 25/26 ppm model, 4 in 1 20/21, 25/26 ppm model

|

1 |

2 3 4 5 |

6 7 8 |

9 |

10 |

11 |

12 |

13 |

14 |

|||||||||||||||

|

24 |

23 |

22 |

21 |

20 |

191817 |

16 15 |

||

|

Figure 1-1-4 |

||||||||

|

1. |

ID Card Copy key |

9. |

Message display |

17. |

OK key |

|||

|

2. |

Copy key |

10. |

Quiet Mode key |

18. |

Cursor key (Up/Down) |

|||

|

3. |

Scan key |

11. |

Menu key |

19. |

Back key |

|||

|

4. |

Address Book key* |

12. |

Density key |

20. |

Attention indicator |

|||

|

5. |

Recall / Pause key* |

13. |

Numeric keys |

21. |

Processing indicator |

|||

|

6. |

Program1 key |

14. |

Clear key |

22. |

On Hook key* |

|||

|

7. |

Program2 key |

15. |

Stop / Reset key |

23. |

FAX key* |

|||

|

8. |

Program3 key |

16. |

Start key |

24. |

Print Box key |

|||

|

*: 4 in |

1 model only |

1-1-12

2M4/2M5/2M6/2M7

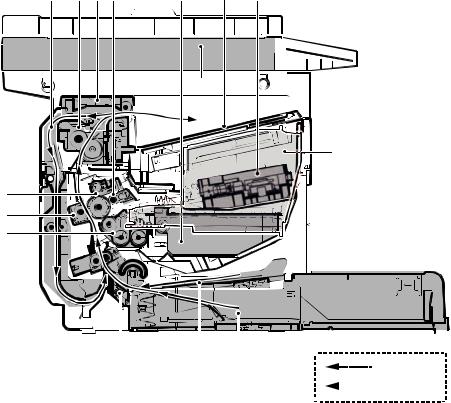

1-1-3 Machine cross section

(1) 20/21 ppm Model

13

3

7

8

4

|

2 |

1 |

Light path |

|||

|

Figure 1-1-5 |

Paper path |

||||

|

1. |

Cassette |

8. |

Transfer/separation section |

||

|

2. |

Paper feed/conveying section |

9. |

Laser scanner unit |

||

|

3. |

Toner container |

10. |

Fuser section |

||

|

4. |

Developing unit |

11. |

Exit section |

||

|

5. |

Wast toner box |

12. |

Top tray |

||

|

6. |

Drum charge roller |

13. |

Scanner section |

||

|

7. |

Drum unit |

1-1-13

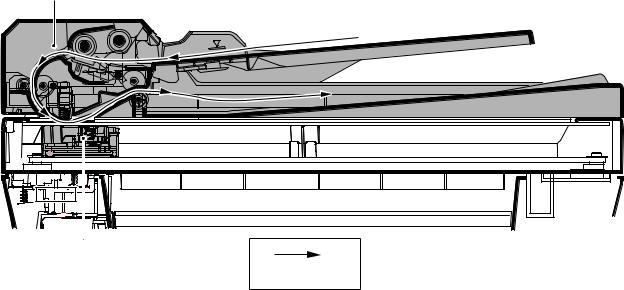

2M4/2M5/2M6/2M7

(2) 25/26 ppm Model

|

13 |

11 12 7 |

6 |

14 |

10 |

15

4

8

9

5

|

Light path |

|||||||||

|

2 |

3 |

1 |

|||||||

|

Paper path |

|||||||||

|

Figure 1-1-6 |

|||||||||

|

1. |

Cassette |

9. |

Transfer/separation section |

||||||

|

2. |

Paper feed/conveying section |

10. |

Laser scanner unit |

||||||

|

3. |

Manual feed tray |

11. |

Fuser section |

||||||

|

4. |

Toner container |

12. |

Feedshift/exit section |

||||||

|

5. |

Developing unit |

13. |

Duplex conveying section |

||||||

|

6. |

Wast toner box |

14. |

Top tray |

||||||

|

7. |

Drum charge roller |

15. |

Scanner section |

||||||

|

8. |

Drum unit |

1-1-14

2M4/2M5/2M6/2M7

(3) ISU/DP Section

17

Original path

Figure 1-1-7

16.Image scanner unit (ISU)

17.Document processor (DP) *

*: DP is only possible on the 3 in1 25/26 ppm model, 4 in1 20/21 and 25/26 ppm model.

1-1-15

2M4/2M5/2M6/2M7

This page is intentionally left blank.

1-1-16

2M4/2M5/2M6/2M7

1-2-1 Installation environment

1.Temperature: 10 to 32.5°C/50 to 90.5°F

2.Humidity: 15 to 80% RH

3.Power supply: 120 V AC, 6.0 A

220 — 240 V AC, 3.1 A

4.Power source frequency: 50 Hz ± 2%/60 Hz ± 2%

5.Installation location

Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other strong light when removing paper jams.

Avoid locations subject to high temperature and high humidity or low temperature and low humidity; an abrupt change in the environmental temperature; and cool or hot, direct air.

Avoid places subject to dust and vibrations.

Choose a surface capable of supporting the weight of the machine.

Place the machine on a level surface (maximum allowance inclination: 1°).

Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

Select a well-ventilated location.

6.Allow sufficient access for proper operation and maintenance of the machine. Machine front : 250 mm/ 10″

Machine rear : 350 mm/ 14″

Machine right : 200 mm/ 8″

Machine left : 200 mm/ 8″

Machine top : 400 mm/ 15 3/4”

3 in 1 25/26 ppm model,4 in 1 20/21,25/26 ppm model

400 mm

(15-3/4″)

|

200 mm |

200 mm |

350 mm |

250 mm |

|

(8″) |

(8″) |

(14″) |

(10″) |

Figure 1-2-1

1-2-1

2M4/2M5/2M6/2M7

3 in 1 20/21 ppm model

400 mm

(15-3/4″)

|

200 mm |

200 mm |

350 mm |

250 mm |

|

(8″) |

(8″) |

(14″) |

(10″) |

Figure 1-2-2

1-2-2

2M4/2M5/2M6/2M7

1-2-2 Unpacking and installation

(1) Installation procedure

Start

Unpacking

Taking out the machine

Removing the tapes

Installing the cassette cover

Loading paper (cassette)

Installing the toner container

Connect the USB cable

Connect the Network cable (25/26 ppm model)

Connect the Modular Cable (4 in 1 model)

Installing the operation panel sheet

Connect the power cord

Installing the toner

Make test printing

Installing the printer driver/ Utilities

Completion of the machine installation.

Figure 1-2-3

1-2-3

2M4/2M5/2M6/2M7

Unpacking

3 in 1 25/26 ppm model,4 in 1 20/21,25/26 ppm model

|

9 |

||

|

16 |

17 |

|

|

8 |

||

|

6 |

15 |

18 |

|

1 |

7 |

|

|

5 |

11 |

|

|

10 |

||

|

3 |

||

|

12 |

||

|

4 |

2

|

13 |

|||||

|

14 |

|||||

|

Figure 1-2-4 |

|||||

|

1. |

Machine |

12. |

Toner container |

||

|

2. |

Outer case |

13. |

CDROM |

||

|

3. |

Bottom left pad |

14. |

Quick installation guide etc. |

||

|

4. |

Bottom right pad |

15. |

Power cord |

||

|

5. |

Machine cover |

16. |

USB cable*1 |

||

|

6. |

Top left pad |

17. |

Modular cable*2 |

||

|

7. |

Top right pad |

18. |

Ferrite core*2 |

||

|

8. |

Top spacer |

*1:China model only |

|||

|

9. |

Operation panel sheets |

*2: The packaging differs depending on |

|||

|

10. |

Spacer |

the destination. |

|||

|

11. |

Cassette cover |

*: Place the machine on a level surface.

1-2-4

2M4/2M5/2M6/2M7

|

3 in 1 20/21 ppm model |

|

|

9 |

|

|

16 |

|

|

8 |

|

|

6 |

15 |

|

1 |

7 |

|

5 |

11 |

|

10 |

|

|

3 |

|

|

12 |

|

|

4 |

2

|

13 |

|||||

|

14 |

|||||

|

Figure 1-2-5 |

|||||

|

1. |

Machine |

10. |

Spacer |

||

|

2. |

Outer case |

11. |

Cassette cover |

||

|

3. |

Bottom left pad |

12. |

Toner container |

||

|

4. |

Bottom right pad |

13. |

CDROM |

||

|

5. |

Machine cover |

14. |

Quick installation guide etc. |

||

|

6. |

Top left pad |

15. |

Power cord |

||

|

7. |

Top right pad |

16. |

USB cable* |

||

|

8. |

Top spacer |

*:China model only |

|||

|

9. |

Operation panel sheets |

*: Place the machine on a level surface.

1-2-5

Removing the tapes

3 in 1 25/26 ppm model,4 in 1 20/21,25/26 ppm model

1. Remove seven tapes.

2. Remove tape.

2M4/2M5/2M6/2M7-1

Tape

Tapes

Figure 1-2-6

Figure 1-2-7

1-2-6

2M4/2M5/2M6/2M7-1

3. Remove five tapes.

Tapes

Tapes

Figure 1-2-8

4. Open the DP.

5. Remove the film.

6. Remove tape.

Tape

Film

Figure 1-2-9

1-2-7

2M4/2M5/2M6/2M7-1

3 in 1 20/21 ppm model

1. Remove seven tapes.

Tape

Tapes

Figure 1-2-10

2. Open the cassette.

3. Remove tape.

Tape

Cassette

Figure 1-2-11

1-2-8

2M4/2M5/2M6/2M7-1

4. Remove three tape.

Tapes

Figure 1-2-12

5.Open the Original Cover.

6.Remove the film.

7. Remove tape.

Film

Tape

Figure 1-2-13

1-2-9

Installing the cassette cover

1.Attach the cassette cover.

Attach the cassette cover so that its right and left-side pins and the boss on

the machine frame mate with each other.

*: If performing installation in a 25/26 ppm model, install the cassette cover so that its guide at the top is positioned above the MF base.

Loading paper (cassette)

1. Open the cassette cover.

2.Adjust the position of the width guides located on the left and right sides of the

cassette.

*: Paper sizes are marked on the cassette.

2M4/2M5/2M6/2M7

Cassette cover

Figure 1-2-14

Cassette cover

Figure 1-2-15

Paper width guides

Figure 1-2-16

1-2-10

2M4/2M5/2M6/2M7

3. Adjust the paper length guide to the paper size required.

Paper length guide

Figure 1-2-17

4. Load the paper all the way in the cassette until the paper touches the far inner side.

*: Ensure the side to be printed is facing up and the paper is not folded, curled, or damaged.

Figure 1-2-18

*: Adjust so that there is no gap between the paper length guide and the paper.

Figure 1-2-19

1-2-11

2M4/2M5/2M6/2M7

*: Load an amount of paper that fits under the tabs on the width guides.

*: Ensure that the loaded paper does not exceed the level indicated.

Tabs

Exceed the level indicated

Figure 1-2-20

5. Close the cassette cover.

Figure 1-2-21

1-2-12

2M4/2M5/2M6/2M7

Installing the toner containers

1. Open the front cover.

Front cover

Figure 1-2-22

2. Take the new toner container out of the toner kit.

3. Shake the new toner container at least

10 times as shown in the figure in order to distribute the toner evenly inside the container.

Figure 1-2-23

4. Install the toner container in the machine.

*: Push in firmly until you hear a “click” sound.

Figure 1-2-24

1-2-13

2M4/2M5/2M6/2M7

5. Close the front cover.

Figure 1-2-25

Connecting the USB Cable

1. Connect the USB cable (not included) to the USB interface connector. Connect the other end of the USB cable to the computer’s USB interface connector.

*: China model only included.

Figure 1-2-26

1-2-14

2M4/2M5/2M6/2M7

Connecting the Network Cable (25/26 ppm model only)

1. Connect the network cable (not included) to the network interface connector.

Connect the other end of the cable to the PC or your network device.

*: Use shielded interface cables.

Figure 1-2-27

Connecting the Modular Cable (4 in 1 model only)

1. Connect the modular cable to the interface connector at the rear of the machine.

Figure 1-2-28

1-2-15

2M4/2M5/2M6/2M7

Install the ferrite core

If a ferrite core is supplied for the destination, follow the following procedure and fit the ferrite core to the modular cables.

1. Open the ferrite core by releasing the two latches.

2. Install the ferrite core onto the modular connecter cable.

3.Wind the modular cables around the ferrite core.

*: Fit the ferrite core on the cables at a distance 35 mm ± 10 mm from the terminal.

4. Close the ferrite core by snapping the two latches in.

35

Modular cable

Figure 1-2-29

1-2-16

Installing the operation panel sheet

1.Affix the operation panel sheet which was supplied.

Connecting the power code

1.Connect the power cord to the power cord connector at the rear of the machine.

2.Connect the other end of the power cord to a power outlet.

2M4/2M5/2M6/2M7

3 in1 25/26 ppm model

4 in1 20/21,25/26 ppm model

Figure 1-2-30

2M4/2M5/2M6/2M7

Installing the toner

1. Press the power switch to On.

2. Starting the toner Installation.

*: The installation is completed when the operation panel shows the following, after approximately 7 minutes.

|

3 in1 25/26 ppm model |

& |

|

4 in1 20/21,25/26 ppm model |

3 in1 20/21 ppm model |

Language

:*English

Make test printing

3 in 1 25/26 ppm model,4 in 1 20/21,25/26 ppm model

1. Draw out the sub tray and lift the paper

1

stopper upright.

Figure 1-2-32

Sub tray

Paper stopper

Figure 1-2-33

2.Use the cursor key to select the language and press OK.

1-2-18

1.Press the Menu key.

2.In the Menu. menu screen, press cursor key to select System menu.Press the OK key.

3.In the System menu screen, press cursor key to select Report.Press the OK key.

4.In the Report menu screen, press cursor key to select Status Page.Press the OK key.

5.In the Status Page menu screen, press cursor key to Yes.Press the OK key.