-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for Polaris Sportsman 550 Touring EPS

Summary of Contents for Polaris Sportsman 550 Touring EPS

-

Page 2

WARNING The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. A card containing important ATV safety information should be attached to the owner’s manual on the next page. If you cannot locate this card, or if it has been removed, please call 1-800- 342-3764 for assistance. -

Page 3

The text is printed on 100% recycled with 40% post-consumer waste (PCW). -

Page 4

NEVER CARRY NEVER USE MORE THAN WITH DRUGS 1 PASSENGER OR ALCOHOL For your nearest Polaris dealer, call 1-800-POLARIS or visit www.polarisindustries.com Polaris Sales Inc., 2100 Hwy 55 Medina, MN 55340 Phone 1-888-704-5290 Part No. 9922090 Rev 02 Printed in USA… -

Page 5

® • Victory Motorcycles ® We believe Polaris sets a standard of excellence for all utility and recre- ational vehicles manufactured in the world today. Many years of experi- ence have gone into the engineering, design, and development of your Polaris vehicle, making it the finest machine we’ve ever produced. -

Page 6

POLARIS, THE WAY OUT and SPORTSMAN are registered trademarks of Polaris Industries Inc. Copyright 2009 Polaris Sales Inc. All information contained within this publication is based on the latest product information at the time of publication. Due to constant improvements in the design and quality of production components, some minor discrep- ancies may result between the actual vehicle and the information presented in this publi- cation. -

Page 7: Table Of Contents

Troubleshooting ….. . . 131 Polaris Products….. . . 135 Specifications .

-

Page 8: Introduction

The following signal words and symbols appear throughout this manual and on your vehicle. Your safety is involved when these words and sym- bols are used. Become familiar with their meanings before reading the manual. The safety alert symbol indicates a potential personal injury hazard. WARNING A WARNING indicates a hazardous situation which, if not avoided, may result in death or serious injury.

-

Page 9: Safety

Failure to heed the warnings and safety precautions contained in this manual can result in severe injury or death. A Polaris ATV is not a toy and can be hazardous to operate. This vehicle handles differently than other vehicles, such as motorcycles and cars.

-

Page 10: Vehicle Identification Numbers

Record your vehicle’s identification numbers and key number in the spaces provided. Remove the spare key and store it in a safe place. An ignition key can be duplicated only by ordering a Polaris key blank (using your key number) and mating it with one of your existing keys.

-

Page 11: Safety

You should review this information on a regular basis. If you purchased a used Polaris ATV in the United States, you can enroll in the ATV RiderCourse for a fee. Call ATV Enrollment Express at (800) 887-2887 or visit www.atvsafety.org.

-

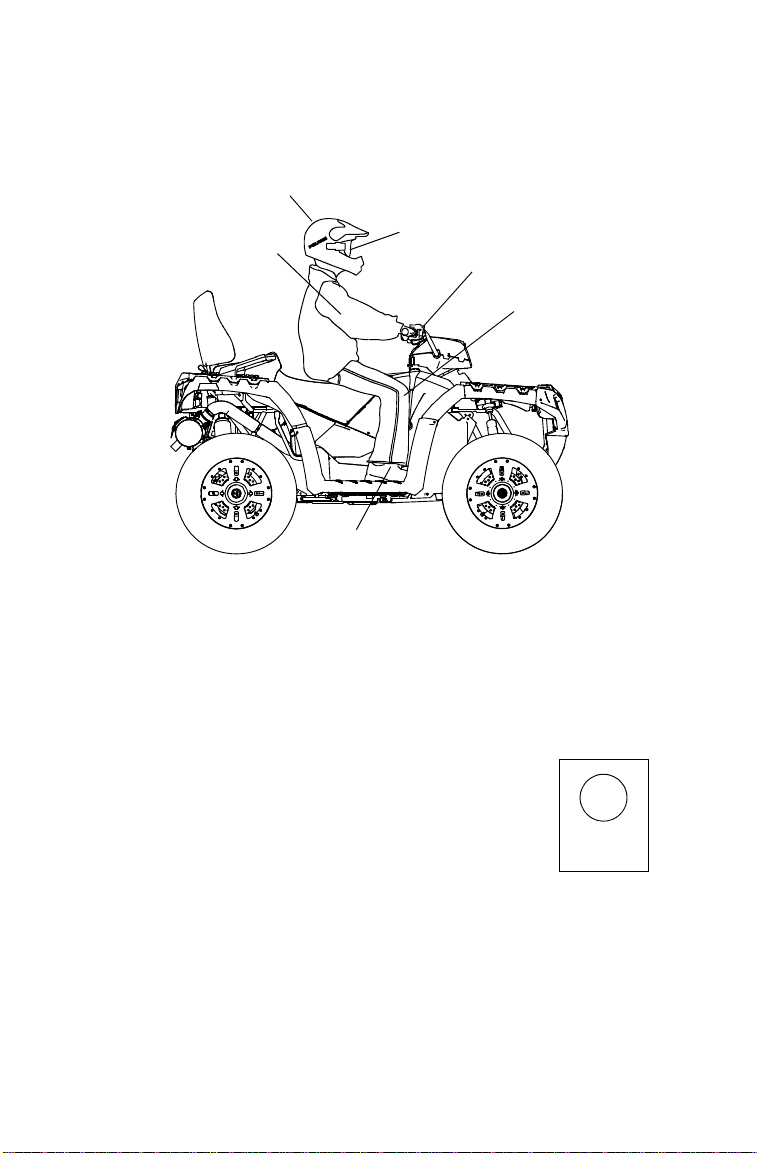

Page 12: Safe Riding Gear

Boots Helmet Wearing a helmet can prevent a severe head injury. Whenever riding a Polaris vehicle, always wear a helmet that meets or exceeds established safety standards. Approved helmets in the USA and Canada bear a U.S. Department of Transportation (DOT) label.

-

Page 13: Eye Protection

Eye Protection Do not depend on eyeglasses or sunglasses for eye protection. When- ever riding a Polaris vehicle, always wear shatterproof goggles or use a shatterproof helmet face shield. Polaris recommends wearing approved Personal Protective Equipment (PPE) bearing markings such as VESC 8, V-8, Z87.1, or CE.

-

Page 14: Safety Warnings

SAFETY Safety Warnings WARNING Failure to operate the ATV properly can result in a collision, loss of control, accident or overturn, which may result in serious injury or death. Heed all safety warnings outlined in this section of the owner’s manual. See the OPERATION section of the owner’s manual for proper operating procedures.

-

Page 15: Handling Gasoline

Safety Warnings Handling Gasoline Gasoline is highly flammable and explosive under certain conditions. • Always exercise extreme caution whenever handling gasoline. • Always refuel with the engine stopped, and outdoors or in a well ventilated area. • Do not smoke or allow open flames or sparks in or near the area where refueling is performed or where gasoline is stored.

-

Page 16: Protective Apparel

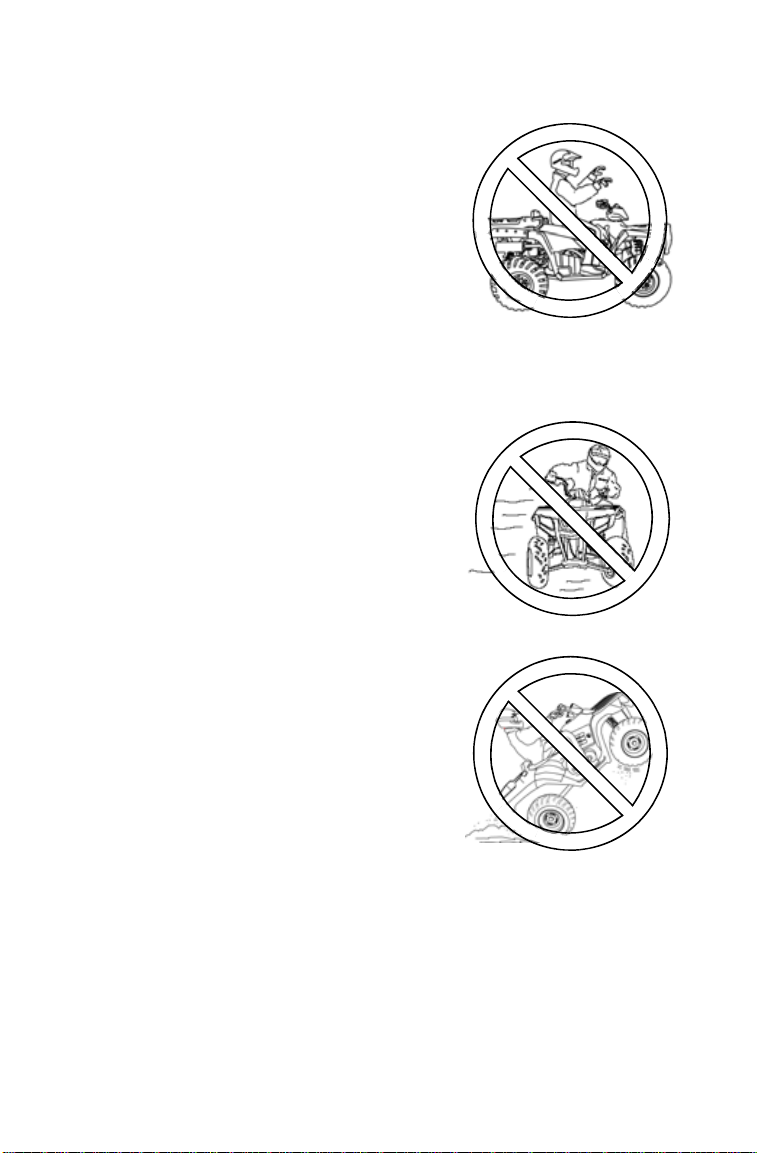

SAFETY Safety Warnings Protective Apparel Riding in this vehicle without wearing an approved helmet and protective eyewear increases the risk of a serious injuries in the event of an accident. Operator and passenger must always wear an approved helmet that fits properly and eye protection (goggles or face shield).

-

Page 17: Operating On Pavement

SAFETY Safety Warnings Operating on Pavement Operating an ATV on paved surfaces (including sidewalks, paths, parking lots and driveways) may adversely affect the handling of the ATV and could result in loss of control and accident or overturn. Avoid operating the ATV on pavement. ATV tires are designed for off-road use.

-

Page 18: Physical Control Of The Atv

SAFETY Safety Warnings Physical Control of the ATV Removing even one hand or foot can reduce ability to control the vehicle or could cause loss of balance and ejection from the ATV. If a person’s feet are not firmly planted on the footrests, they could come into contact with the wheels or other moving parts and lead to accident or injury.

-

Page 19: Improper Hill Climbing

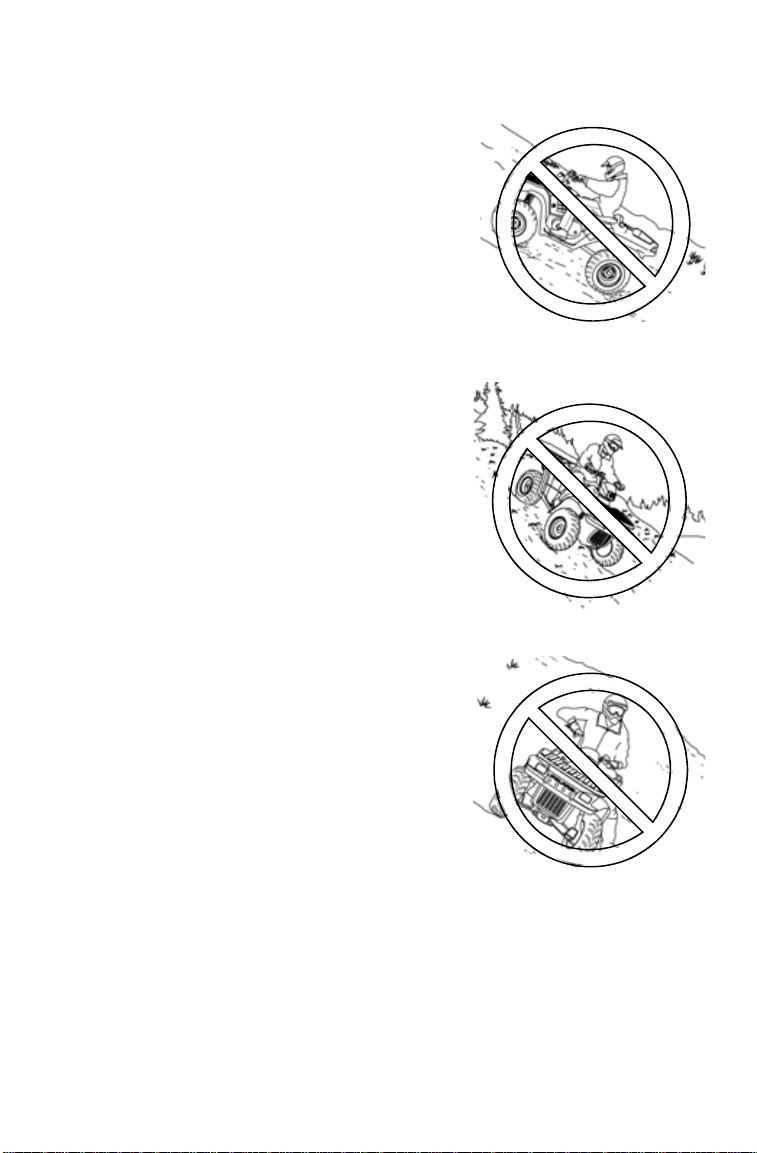

Safety Warnings Improper Hill Climbing Improper hill climbing could cause loss of control or overturn. Always follow proper procedures for climbing hills as described in the owner’s manual. See page 63. Always move the 4X4 switch to ADC 4X4 before ascending or descending a hill. Descending Hills Improperly Improperly descending a hill could cause loss of control or overturn.

-

Page 20: Stalling While Climbing A Hill

SAFETY Safety Warnings Stalling While Climbing a Hill Stalling, rolling backwards or improperly dismounting while climbing a hill could cause an overturn. • Always maintain a steady speed when climbing a hill. • Always move the 4X4 switch to ADC 4X4 before ascending or descending a hill.

-

Page 21: Operating On Slippery Terrain

SAFETY Safety Warnings Operating on Slippery Terrain Failure to use extra caution when operating on excessively rough, slippery or loose terrain could cause loss of traction, loss of control, accident or overturn. Do not operate on excessively rough, slippery or loose terrain until you’ve learned and practiced the skills necessary to control the ATV on such terrain.

-

Page 22: Skidding Or Sliding

SAFETY Safety Warnings Improper Tire Maintenance Operating this ATV with improper tires or with improper or uneven tire pressure could cause loss of control or accident. Always use the size and type of tires specified for your ATV. Always maintain proper tire pressure as described in the owner’s manual and on safety labels.

-

Page 23: Improper Cargo Loading

Safety Warnings Operating Through Deep Water Operating the ATV through deep or fast- flowing water could cause the tires to float, causing loss of control or overturn. Avoid operating the ATV through deep or fast-flowing water. If it’s unavoidable to enter water that exceeds the recommended maximum depth (see page 68):…

-

Page 24: Poor Visibility

SAFETY Safety Warnings Operating on Frozen Bodies of Water Operating on frozen bodies of water may result in serious injury or death if the ATV and/or riders fall through the ice. Never operate the ATV on a frozen body of water.

-

Page 25: Operating A Damaged Atv

SAFETY Safety Warnings Operating a Damaged ATV Operating a damaged ATV can result in an accident. After any overturn or accident, have a qualified service dealer inspect the entire machine for possible damage, including (but not limited to) brakes, throttle and steering systems. Physical Skills Safe operation of this rider-active vehicle requires good judgement and physical skills.

-

Page 26: Age 16 Warning

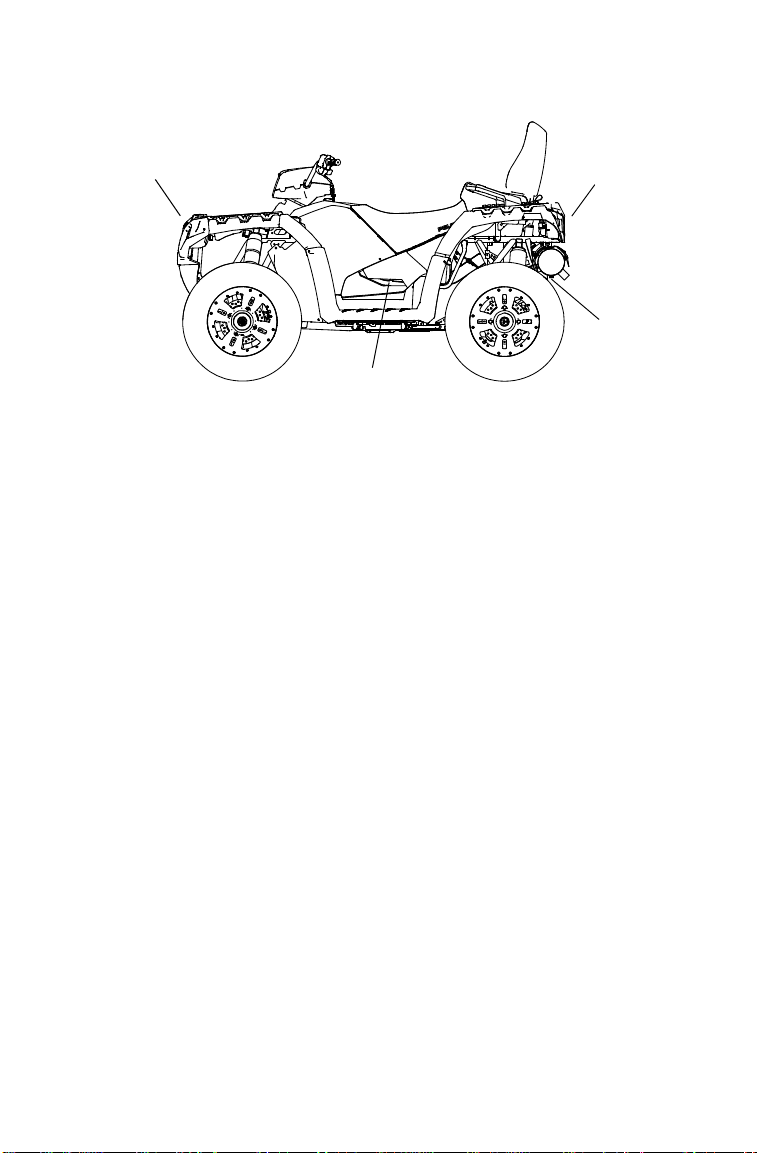

If an informational or graphic label becomes illegible or comes off, con- tact your Polaris dealer to purchase a replacement. Replacement safety labels are provided by Polaris at no charge. The part number is printed on the label. Reverse Override Warning/AWD Caution…

-

Page 27: General Warning

Safety Labels and Locations General Warning WARNING Improper ATV use can result in SEVERE INJURY or DEATH ALWAYS USE AN APPROVED HELMET AND PROTECTIVE GEAR FOR DRIVER AND PASSENGER NEVER USE ON PUBLIC ROADS NEVER CARRY MORE THAN 1 PASSENGER NEVER USE WITH DRUGS OR ALCOHOL NEVER operate: •…

-

Page 28: Tire Pressure/Load Warning

Safety Labels and Locations Passenger Warning/Discretionary Warning WARNING PASSENGER SAFETY To reduce the risk of SEVERE INJURY or DEATH NEVER CARRY MORE THAN ONE PASSENGER NEVER RIDE AFTER USING DRUGS OR ALCOHOL NEVER carry a passenger too small to firmly plant feet on footrests and securely grasp hand holds.

-

Page 29: Clutch Cover Warning

Safety Labels and Locations Rack/Box Warning Rack/Box Warning WARNING • DO NOT TOW FROM RACK OR BUMPER. Vehicle damage or tipover may result causing severe injury or death. Tow only from tow hooks or hitch. • Maximum Rack Loads: Front 120 lbs. (54 kg) Rear 240 lbs. (109 kg) Clutch Cover Warning WARNING •…

-

Page 30: Features And Controls

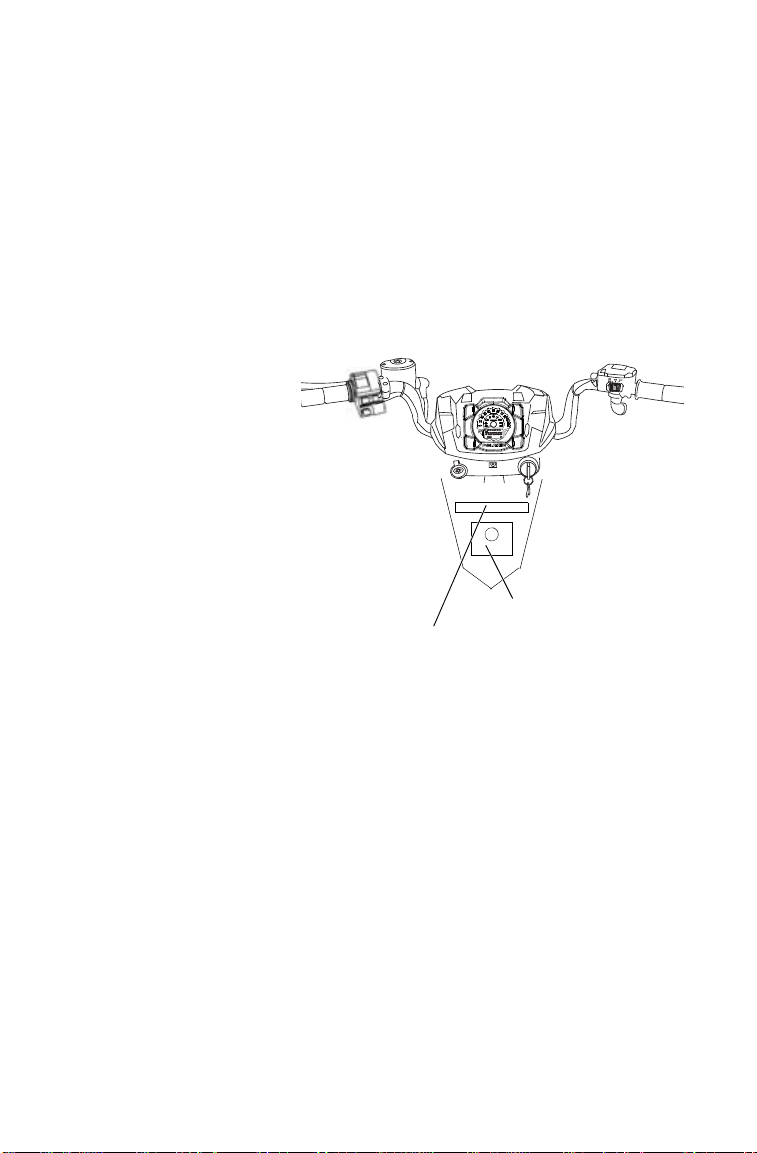

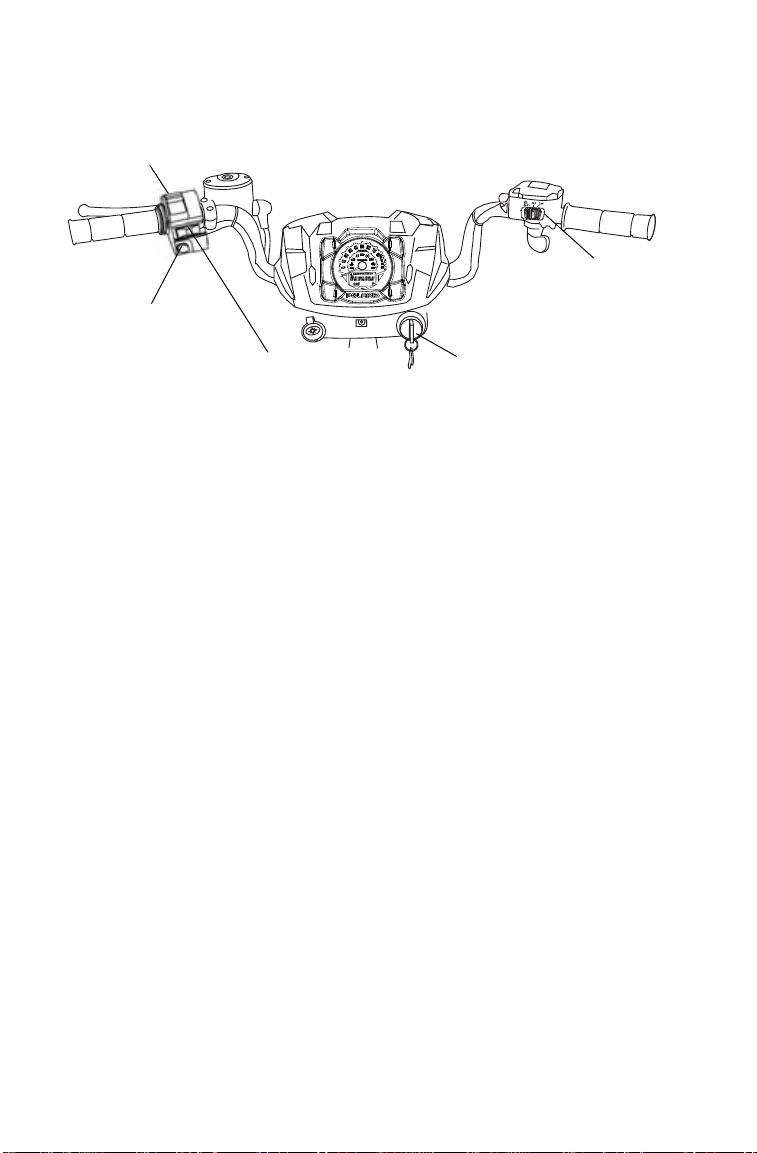

FEATURES AND CONTROLS Switches Headlight Switch Switch Mode/Reverse Override Switch Main Key Engine Switch Stop Switch Mode/Reverse Override Switch This vehicle is equipped with a reverse speed limiter system.To gain additional wheel speed while backing, depress the override switch. WARNING! Pressing the override button while the throttle is open can cause loss of control, which may result in serious injury or death.

-

Page 31: Engine Stop Switch

FEATURES AND CONTROLS Switches Engine Stop Switch Move the stop switch either left or right to the OFF position to stop the engine quickly. Move the stop switch to the RUN position before attempt- ing to start the engine. The engine will not start or run when the switch is off.

-

Page 32: Operation

The throttle lever is spring loaded. Engine speed returns to idle when the lever is released. This ATV is equipped with Polaris Electronic Throttle Con- trol (ETC), which is designed to reduce the risk of a frozen or stuck throttle.

-

Page 33: Brake Lever

FEATURES AND CONTROLS Brake Lever WARNING Operating the ATV with a spongy brake lever can result in loss of braking, which could cause an accident. Never operate the ATV with a spongy-feeling brake lever. Always contact your dealer for service before operating the vehicle. Squeeze the brake lever toward the handlebar to apply the front and rear brakes.

-

Page 34

FEATURES AND CONTROLS Master Cylinder/Brake Fluid WARNING An over-full master cylinder may cause brake drag or brake lock-up, which could result in an accident. Maintain brake fluid at the recommended level. Do not overfill. Never store or use a partial bottle of brake fluid. Brake fluid is hygroscopic, meaning it rapidly absorbs moisture from the air. -

Page 35: Parking Brake

Parking Brake Locking the Parking Brake 1. Place the transmission in PARK. 2. Squeeze and release the brake lever two or three times, then squeeze and hold. 3. Push the parking brake lock forward to engage the lock. 4. Release the brake lever. 5.

-

Page 36

FEATURES AND CONTROLS Auxiliary Foot Brake WARNING Aggressively applying the auxiliary brake when backing down a hill may cause rear tipover, which could result in serious injury or death. Never back down a hill. Use caution when applying the auxiliary brake. Do not aggressively apply the auxiliary brake when going forward. -

Page 37

FEATURES AND CONTROLS Automatic Transmission Gear Selector The transmission gear Gear selector is located on the Selector right side of the vehicle. H: High Gear L: Low Gear N: Neutral R: Reverse P: Park To shift gears, brake to a complete stop. -

Page 38: Passenger Seat

Test the seat latch by attempting to pull the seat upward. If the lock-out is not working properly, do not allow a passenger to ride the vehicle. See your Polaris dealer for ser- vice. See pages 95-96 for passenger seat adjustment procedures.

-

Page 39: Fuel Tank

FEATURES AND CONTROLS Fuel Tank Always refuel with the engine Fuel Tank stopped, and outdoors or in a well ventilated area. Refuel on a level surface. Remove the fuel tank cap and add fuel. Use either leaded or unleaded gasoline with a minimum pump octane number of 87=(R+ M/2) octane.

-

Page 40

FEATURES AND CONTROLS Front Storage Box Open the front storage box to access the under-compartment area. 1. Release the front box cover latches and lift the cover. 2. Release the plunger latches that secure the box to the frame. 3. Close the cover and lift the unlatched edge of the box to disengage the plungers. -

Page 41: All Wheel Drive System

FEATURES AND CONTROLS All Wheel Drive System The All Wheel Drive system is ADC 4X4 controlled by the 4X4 switch. ADC 4X4 Mode When the switch is on ADC 4X4, the ADC system allows engine braking to all four wheels when the vehicle descends a hill or incline.

-

Page 42: Engaging 4X

FEATURES AND CONTROLS All Wheel Drive System Engaging 4X4 The 4X4 switch may be turned on or off while the vehicle is moving. Initially, the vehicle’s electronic system will not enable 4X4 until the engine RPM is below 3100. Once enabled, 4X4 remains enabled until the 4X4 switch is turned off.

-

Page 43: Engaging Active Descent Control

FEATURES AND CONTROLS Active Descent Control (ADC) System The ADC system allows engine braking to all four wheels when the vehicle descends a hill or incline. Always move the 4X4 switch to ADC 4X4 before ascending or descending a hill. Engaging Active Descent Control The ADC system will automatically engage when all four of the follow- ing conditions occur:…

-

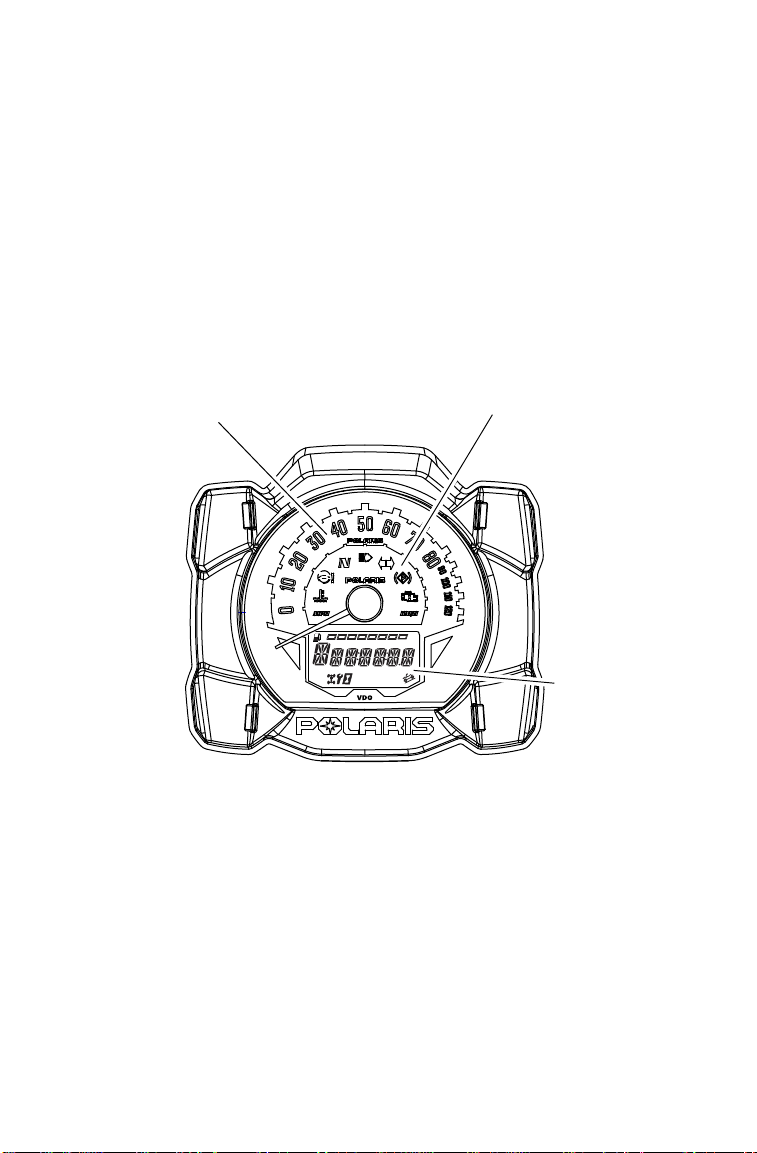

Page 44: Instrument Cluster

Instrument Cluster Your ATV is equipped with an instrument cluster that senses vehicle speed from a gear in the transmission. The instrument cluster measures distance in miles/kilometers as well as hours of operation. In addition to showing vehicle speed, the instrument cluster also dis- plays the following items: engine speed, odometer, resettable trip meters (2), total engine hours of operation, service interval timer and indicator, gear position, fuel level, AWD status, EPS status (if equipped), high…

-

Page 45: Rider Information Center

If this occurs, take the ATV to your Polaris dealer for proper diagno- sis. The information center is set to display standard units of measurement and a 12-hour clock at the factory.

-

Page 46

12. EPS Warning Indicator — This indicator illuminates when the key is turned to the ON position and goes off when the engine is started. If the light remains on after starting the engine, the EPS system is inoperative. See your authorized Polaris dealer for service. -

Page 47

Instrument Cluster Rider Information Center Speed Display Area Use the MODE button to toggle through the speed display options. MODE button operation is locked out at speeds above approximately 15 MPH (25 km/h). Tip: The reverse override button also acts as a MODE button when held down for approximately one half second. -

Page 48: Standard/Metric Display

Instrument Cluster Rider Information Center Information Display Area Use the SELECT button (SEL) to toggle through the information area options. SELECT button operation is locked out at speeds above approximately 15 MPH (25 km/h). Tip: The reverse override button also acts as the SELECT button when pressed and released quickly.

-

Page 49: Information Display Area

FEATURES AND CONTROLS Instrument Cluster Rider Information Center Information Display Area Odometer Mode The odometer records and displays the distance traveled by the ATV. Trip Meter Mode The trip meters record the distance traveled by the ATV on each trip if reset before each trip.

-

Page 50

FEATURES AND CONTROLS Instrument Cluster Rider Information Center Information Display Area Programmable Service Interval When the hours of engine operation equal the programmed service interval setting, the wrench icon will flash for 5 seconds each time the engine is started. When this feature is enabled, it provides a convenient reminder to perform routine maintenance. -

Page 51

Diagnostic Display Mode The EFI diagnostic display mode is for informational purposes only. Please see your Polaris dealer for all major repairs. The diagnostic mode is accessible only when the check engine warning indicator activates after the key has been turned on. Leave the key on if you want to view the active code (failure code). -

Page 52

Short-to-Battery: The wire leading from the item listed in the chart to the electronic control unit is shorted to a wire at battery voltage. SPORTSMAN 550 Touring EPS Diagnostic Codes Component Throttle Position Sensor… -

Page 53

Instrument Cluster Rider Information Center SPORTSMAN 550 Touring EPS Diagnostic Codes Component Idle Air Control Starter Enable Circuit All Wheel Drive Control System Power Throttle Safety Signal Active Descent Control System Steering Over Current Shut Down Steering Excessive Current Error… -

Page 54

FEATURES AND CONTROLS Instrument Cluster Rider Information Center SPORTSMAN 850 Touring EPS Diagnostic Codes Component Throttle Position Sensor Engine Temperature Sensor Intake Air Temperature Sensor Manifold Absolute Pressure Sensor Crankshaft Position Sensor Vehicle Speed Signal Gear Sensor Signal Injector 1 (MAG) (SDI Part Load) Injector 2 (PTO) (SDI Part Load) Ignition Coil Primary Driver 1 (MAG) Ignition Coil Primary Driver 2 (PTO) -

Page 55

Instrument Cluster Rider Information Center SPORTSMAN 850 Touring EPS Diagnostic Codes Component Chassis Relay All Wheel Drive Control System Power Throttle Safety Signal Active Descent Control System Idle Speed Steering Over Current Shutdown Current Above Normal/Grounded Steering Excessive Current Error Current Above Normal/Grounded Steering Torque Sensor T1 Par- tial Failure Steering Torque Sensor T2 Par-… -

Page 56: Operation

Break-In Period The break-in period for your new Polaris ATV is the first ten hours of operation, or the time it takes to use the first two full tanks of gasoline. No single action on your part is as important as following the proce- dures for a proper break-in.

-

Page 57

Break-In Period Engine and Drivetrain Break-in 1. Fill the fuel tank with gasoline. See page 35. Always exercise extreme caution whenever handling gasoline. 2. Check the engine oil level on the dipstick. See page 81. Add oil if necessary to maintain the level between the safe and add marks. 3. -

Page 58: Pre-Ride Checklist

OPERATION Pre-Ride Checklist Failure to inspect and verify that the ATV is in safe operating condition before operating increases the risk of an accident. Always inspect the ATV before each use to make sure it’s in safe operating condition. Item Passenger seat latch Brake system/lever travel Brake fluid…

-

Page 59: Safe Operation Practices

Safe Operation Practices 1. Complete the recommended safety training before operating this vehicle. See page 7. 2. Do not allow anyone under 16 years of age to operate this vehicle. Do not allow anyone with cognitive or physical disabilities to oper- ate this vehicle.

-

Page 60: Trail Etiquette

Respect the environment in which you ride. Find out where the designated riding areas are by con- tacting your Polaris dealer, a local riding club or local officials. Help keep our trails open for recreational vehicle use. As an off-road enthusiast, you represent the sport and can set a good example (or a poor example) for others to follow.

-

Page 61: Starting The Engine

Starting the Engine 1. Position the vehicle on a level surface outdoors or in a well-venti- lated area. 2. Place the transmission in PARK. 3. Lock the parking brake. Tip: The starter interlock will prevent the engine from starting if the transmission is in gear and the brake is not engaged.

-

Page 62

OPERATION Driving Procedures 1. Wear protective riding gear. See page 8. 2. Perform the pre-ride inspection. See page 54. 3. Place the transmission in PARK. 4. Lock the parking brake. 5. Mount the vehicle from the left side. 6. Sit upright with both feet on the footrests and both hands on the handlebars. -

Page 63: Turning The Vehicle

Turning the Vehicle Both rear wheels drive equally at all times. This means that the outside wheel must travel a greater distance than the inside wheel when turning, and the inside tire must slip traction slightly. 1. Slow down. 2. Never turn quickly when carrying a passenger or cargo.

-

Page 64: Driving With A Passenger

Driving with a Passenger 1. Never allow anyone under 12 years of age to ride as a passenger on this 2-up ATV. Make sure any passenger is tall enough to comfort- ably and safely reach the grab handles and footrests. 2.

-

Page 65

Driving with a Passenger 11. Ride to the ability of your passenger, instead of to your own ability. Avoid unexpected or aggressive maneuvers that could cause a pas- senger to fall from the vehicle. 12. Do not cross a hillside with a passenger on board. See page 64. 13. -

Page 66: Driving On Slippery Surfaces

Driving on Slippery Surfaces Whenever riding on slippery surfaces such as wet trails or loose gravel, or during freezing weather, follow these precautions: 1. Do not operate on excessively rough, slippery or loose terrain. 2. Slow down when entering slippery areas. 3.

-

Page 67: Driving Uphill

Driving Uphill Braking and handling are greatly affected when operating in hilly ter- rain. Improper procedure could cause loss of control or overturn. When- ever traveling uphill, follow these precautions: 1. Always move the 4X4 switch to ADC 4X4 before ascending or descending a hill.

-

Page 68

Driving on a Sidehill (Sidehilling) Driving on a sidehill is not recommended. Improper procedure could cause loss of control or overturn. Avoid crossing the side of any hill unless absolutely necessary. If crossing a sidehill is unavoidable, follow these precautions: 1. -

Page 69: Driving Downhill

Driving Downhill When driving downhill, follow these precautions: 1. Always check the terrain carefully before descending a hill. 2. Always move the 4X4 switch to ADC 4X4 before ascending or descending a hill. See page 39. 3. Always descend a hill with the transmission in forward gear. Do not descend a hill with the transmission in neutral.

-

Page 70

OPERATION Turning Around on a Hill (K-Turn) If the vehicle stalls while climbing a hill, never back it down the hill! Use the K-turn to turn around. 8 ft. (2.4 m) -

Page 71

Turning Around on a Hill (K-Turn) 1. Stop and lock the parking brake while keeping body weight uphill. 2. Always move the 4X4 switch to ADC 4X4 before ascending or descending a hill. See page 39. 3. Leave the transmission in forward and shut off the engine. 4. -

Page 72: Driving Through Water

OPERATION Driving Through Water Your ATV can operate through water with a maximum recommended depth equal to the bottom of the footrests. Follow these procedures when operating through water: 1. Determine water depths and current before entering water. 2. Choose a crossing where both banks have gradual inclines.

-

Page 73: Driving Over Obstacles

Driving Over Obstacles Follow these precautions when operating over obstacles: 1. Always check for obstacles before operating in a new area. 2. Look ahead and learn to read the terrain. Be constantly alert for haz- ards such as logs, rocks and low hanging branches. 3.

-

Page 74: Driving In Reverse

Driving in Reverse Follow these precautions when operating in reverse: 1. Always check for obstacles or people behind the vehicle. Be aware that a passenger can obstruct your view. 2. Always avoid backing downhill. 3. Back slowly. 4. Apply the brakes lightly for stopping. 5.

-

Page 75: Parking On An Incline

OPERATION Parking on an Incline Avoid parking on an incline if possible. If it’s unavoidable, follow these precautions: 1. Stop the engine. 2. Place the transmission in PARK. 3. Lock the parking brake. 4. Always block the rear wheels on the downhill side.

-

Page 76: Hauling Cargo

OPERATION Hauling Cargo WARNING Overloading the vehicle or carrying or towing cargo improperly can alter vehicle handling and may cause loss of control or brake instability, which can result in serious injury or death. Always follow these precautions when hauling cargo: Never carry cargo on the rear rack when operating the ATV in the 2-up mode with a passenger.

-

Page 77

Hauling Cargo Never exceed the weight capacities specified for your ATV on warning labels and in the specifications sec- tion of this manual. 1. Cargo weight should be evenly distributed (1/3 on the front rack and 2/3 on the rear rack) and mounted as low as possible. -

Page 78: Towing Loads

ATV warranty. Never install a hitch longer than 4″ (10 cm). Never install automotive accessories on your Polaris ATV. Always install Polaris- approved (or equivalent) accessories designed for ATV use. Maximum Towing Capacities Do not exceed maximum towing capacities. Avoid towing on inclines.

-

Page 79: Emission Control Systems

CFR 205) and local noise level requirements. Operation on Public Lands in the U.S.A. Your Polaris vehicle has a spark arrestor that was tested and qualified to be in accordance with the USFS standard 5100-1c. Federal law requires that this spark arrestor be installed and functional when the vehicle is operated on public lands.

-

Page 80: Maintenance

Inspect, clean, lubricate, adjust and replace parts as necessary. When inspection reveals the need for replacement parts, use genuine Polaris parts available from your Polaris dealer. Record maintenance and service in the Maintenance Log beginning on page 149.

-

Page 81: Periodic Maintenance Chart

Improperly performing the procedures marked with a component failure and cause an accident, which may result in serious injury or death. Always have an authorized Polaris dealer perform these services. Maintenance Chart Key Perform these operations more often for vehicles subjected to severe use.

-

Page 82

MAINTENANCE Periodic Maintenance Chart Item Hours Calendar Air filter, main element Engine oil change Brake pad wear Battery ADC fluid Rear gearcase oil (if equipped) Transmission oil Demand drive fluid General lubrication Throttle Cable/ ETC Switch E Throttle Body Intake Duct Drive belt Cooling system Radiator… -

Page 83

Valve clearance 1000 H Toe adjustment Headlight aim Perform these procedures more often for vehicles subjected to severe use. E Emission-Related Service Have an authorized Polaris dealer perform these services. Maintenance Interval (whichever comes first) Miles (Km) 100 H 12 M 1000 (1600) Inspect;… -

Page 84: Lubrication Guide

Fluid (or GL5 80- 90 weight gear lube) Brake Fluid DOT 4 Only ADC Fluid Demand Drive PLUS Fluid Front Prop Polaris Premium Shaft Yoke U-Joint Lube Front Prop Shaft Yoke Capacity Fill Plug at Fluid Torque Change 2 qt.

-

Page 85: Engine Oil

2W-50 4-cycle oil or a similar oil for this engine. See the table on page 80 for fluid recommendations, capacities and plug torques. Oil may need to be changed more frequently if Polaris oil is not used. Always use 2W-50 oil. Follow the manufacturer’s recommendations for ambient temperature operation.

-

Page 86: Oil And Filter Change

Engine Oil Oil and Filter Change See the table on page 80 for fluid recommendations, capacities and plug torques. Always change the oil and filter at the intervals outlined in the Periodic Maintenance Chart beginning on page 76. Always change the oil filter whenever changing oil.

-

Page 87

Oil and Filter Change 9. Place shop towels beneath the oil filter. Using an oil fil- ter wrench (available from your Polaris dealer), turn the filter counter-clockwise to remove it. 10. Using a clean dry cloth, clean the filter sealing surface on the crankcase. -

Page 88: Transmission Oil

Transmission Oil Polaris recommends the use of Polaris Synthetic SPORTSMAN XP Transmission Fluid for this transmission. See the table on page 80 for fluid recommendations, capacities and plug torques. Always check and change the transmission oil at the intervals outlined in the Periodic Maintenance Chart beginning on page 76.

-

Page 89: Oil Change

Transmission Oil Oil Change 1. Remove the footwell. 2. Place a drain pan under the gearcase. Remove the drain plug. Allow the oil to drain completely. 3. Clean and reinstall the drain plug. Torque to specification. 4. Remove the fill plug. Add the proper amount of the recommended oil.

-

Page 90: Fluid Change

Always check and change the demand drive fluid at the inter- vals outlined in the Periodic Maintenance Chart beginning on page 76. See page 135 for the part numbers of Polaris products. Use the recommended fluid. Use of other fluids may result in improper operation of components.

-

Page 91: Rear Gearcase Oil

Always check and change the rear gearcase oil at the intervals outlined in the Periodic Maintenance Chart beginning on page 76. See page 135 for the part numbers of Polaris products. The fill plug is located on the rear of the gearcase. The drain plug is located on the bottom of the gearcase.

-

Page 92

We recommend the use of Polaris Demand Drive Plus Fluid for the ADC unit. Maintain the fluid level between the minimum and maximum marks on the reservoir. See page 135 for the part numbers of Polaris products. NOTICE: Do not use brake fluid. Brake fluid will damage rubber components in the hydraulic system. -

Page 93

Active Descent Control (ADC) Fluid Fluid Change 1. Position the vehicle on a level surface. Before performing the fluid change, allow the vehicle to sit for at least 30 minutes. 2. Thoroughly clean the areas around and on the ADC reservoir and bleeder valves (one on each side of the differential). -

Page 94: Cooling System

Steering Assembly The steering assembly of the ATV should be checked periodically for loose nuts and bolts. If loose nuts and bolts are found, see your Polaris dealer for service before operating the vehicle. Cooling System The engine coolant level is controlled, or maintained, by the recovery system.

-

Page 95

Cooling System Recovery Bottle Coolant The recovery bottle fluid level can be viewed from inside the front right wheel well. Access the recovery bottle cap under the front box. See page 1. View the fluid level in the bottle. 2. If the level is low, remove the bottle cap and add coolant as needed. Maintain the coolant level between the minimum and maximum marks on the bottle (when the fluid is cool). -

Page 96: Radiator Coolant

Radiator Coolant To ensure that the coolant maintains its ability to protect the engine, Polaris recommends that you drain the system completely every two years and add a fresh mixture of antifreeze and water. Replace the coolant any time the cooling system has been drained for maintenance or repair.

-

Page 97: Hand Brake

Brakes Hand Brake The front and rear brakes are hydraulic disc brakes, activated by moving the single brake lever toward the handlebar. These brakes are self- adjusting. Under normal operation, the diaphragm extends into the reservoir as fluid level drops. If the fluid level is low and the diaphragm is not extended, a leak is likely and the diaphragm should be replaced.

-

Page 98: Toe Alignment

0″ to 1/8″ (0-3 mm) toe out alignment. 5. Repeat the measurement procedure on the other side of the vehicle. 6. If you discover improper alignment, see your Polaris dealer for ser- vice. Stand…

-

Page 99

Seats Passenger Seat Removal 1. Pull the latch at the rear of the seat. 2. Pivot the rear of the seat upward and remove the front legs of the seat base from the frame. 3. To reinstall the seat, position the front legs of the seat base under the frame. -

Page 100

MAINTENANCE Seats Passenger Seat Suspension 1. Remove the passenger seat. 2. Remove the fastener retaining the passenger seat shock to the passenger seat support. 3. Pivot the seat support upward to access the lower shock fastener. Remove the lower shock fastener. 4. -

Page 101

MAINTENANCE Side Panel/Footwell Removal 1. Remove the seat before removing a side panel. 2. Remove the fasteners securing the side panel or footwell to remove Plastic Rivet Hex Head Screw Plastic Rivet… -

Page 102: Tire Tread Depth

MAINTENANCE Tires WARNING Operating your ATV with worn tires, improperly inflated tires, non-standard tires or improperly installed tires will affect vehicle handling and could cause an accident resulting in serious injury or death. Always follow all tire maintenance procedures as outlined in this manual and on the labels on the vehicle. Always use original equipment size and type when replacing tires.

-

Page 103: Wheel Removal

Tires Front Wheel Hub Tightening Front wheel bearing tightness and spindle nut retention are critical com- ponent operations. All service must be performed by your authorized Polaris dealer. Wheel Removal 1. Stop the engine. 2. Place the transmission in PARK.

-

Page 104: Wheel Installation

Tires Wheel Installation 1. Place the transmission in PARK. 2. Lock the parking brake. 3. Place the wheel on the hub with the valve stem toward the outside and rotation arrows on the tire pointing toward forward rotation. 4. Install the wheel nuts and finger-tighten them. 5.

-

Page 105: Air Filter

Air Filter 1. Remove the seat. 2. Remove the air box cover screws, and remove the air box cover. 3. Remove the filter. 4. Remove the fabric type pre- filter from the main filter. Wash the pre-filter in soapy water, then rinse and let dry. 5.

-

Page 106: Fuse Replacement

MAINTENANCE Fuse Replacement If the engine stops or will not start, or if you experience other electrical failures, a fuse may need replacement. Locate and correct any short cir- cuits that may have caused the blown fuse, then replace the fuse. Spare fuses are provided in the fuse box.

-

Page 107: Headlight Lamp Replacement

Lights Poor lighting can result in reduced visibility when driving. Headlight and taillight lenses become dirty during normal operation. Clean head- lights frequently and replace burned out headlamps promptly. Always make sure lights are adjusted properly for best visibility. Headlight Lamp Replacement When servicing a halogen lamp, avoid touching the lamp with bare fin- gers.

-

Page 108: High Beam Adjustment

Lights High Beam Adjustment The headlight beam can be adjusted slightly upward or downward. Use the following procedure to make the adjustment. 1. Position the vehicle on a level surface with the headlight approxi- mately 25 ft. (7.6 m) from a wall. Place the transmission in PARK. 2.

-

Page 109

Lights Low Beam Adjustment The low beam can be adjusted slightly upward or downward. 1. Loosen the phillips screw located at the rear of the headlamp. 2. Tilt the headlamp upward or downward. 3. Tighten the screw. MAINTENANCE Phillips Screw… -

Page 110: Headlight Housing Replacement

MAINTENANCE Lights Headlight Housing Replacement 1. Remove the five (5) headlight pod screws. 2. Lift the pod cover and disconnect the speedometer harnesses from the speedometer. 3. Unplug the headlamp from the wiring harness. 4. Use a small screwdriver to remove the o-rings from the headlight mounting tabs.

-

Page 111: Lower Headlamp Replacement

Lights Lower Headlamp Replacement 1. Turn the back of the headlight harness counter-clockwise and pull the harness assembly away from the headlight assembly. 2. Remove the headlamp and install the new headlamp. 3. Reinstall the harness assembly into the headlight assembly. 4.

-

Page 112: Spark Plugs

Refer to the specifications section beginning on page 136 for the recom- mended spark plug type and gap for your vehicle. Torque spark plugs to specification. NOTICE: Using non-recommended spark plugs can result in serious engine damage. Always use Polaris-recommended spark plugs. Plug Condition New Spark Plug Previously Installed…

-

Page 113

MAINTENANCE Spark Plugs Spark Plug Inspection Normal Spark Plug The normal insulator tip is gray, tan or light brown. There will be few combustion deposits. The electrodes are not burned or eroded. This indi- cates the proper type and heat range for the engine and the service. The tip should not be flaky and white. -

Page 114: Vehicle Immersion

Vehicle Immersion If your vehicle becomes immersed, major engine damage can result if the machine is not thoroughly inspected. Take the vehicle to your dealer before starting the engine. If it’s impossible to take your ATV to a dealer before starting it, follow the steps outlined below. 1.

-

Page 115: Spark Arrestor

Spark Arrestor WARNING Failure to heed the following warnings while servicing the spark arrestor could result in serious injury or death. Never run the engine in an enclosed area. Remove any combustible materials from the area. Wear eye protection and leather work gloves.

-

Page 116: Pvt System

• Always follow all recommended maintenance procedures. See your dealer as outlined in the owner’s manual. • This PVT system is intended for use on Polaris products only. Do not install it in any other product. • Always make sure the PVT housing is securely in place during operation.

-

Page 117

MAINTENANCE PVT System The basic operation of the Polaris PVT system is dependent on engine speed and vehicle torque requirements. As engine speed increases, the force exerted on the movable drive sheave by the flyweights also increases. This, in turn, increases the amount of pinch applied to the drive belt. -

Page 118: Pvt Drying

PVT System When To Use Low Range and High Range Operating at speeds less than 7 MPH (11 km/h) Towing heavy loads Operating in rough terrain (swamps, mountains, etc.) Operating at speeds greater than 7 MPH (11 km/h) PVT Drying There may be some instances when water is accidently ingested into the PVT system.

-

Page 119

Battery WARNING Improperly connecting or disconnecting battery cables can result in an explosion and cause serious injury or death. When removing the battery, always disconnect the negative (black) cable first. When reinstalling the battery, always connect the negative (black) cable last. WARNING Battery electrolyte is poisonous. -

Page 120: Battery Removal

MAINTENANCE Battery Battery Removal 1. Remove the passenger seat and the seat pivot bolt. 2. Disconnect the black (negative) battery cable first. 3. Disconnect the red (positive) battery cable last. 4. Disconnect the battery hold-down strap. 5. On conventional batteries, remove the battery vent tube. 6.

-

Page 121: Battery Installation

Battery Battery Installation Using a new battery that has not been fully charged can damage the bat- tery and result in a shorter life. It can also hinder vehicle performance. Follow the battery charging instructions on page 119 before installing the battery.

-

Page 122: Battery Storage

Check battery voltage each month during storage and recharge as needed to maintain a full charge. Polaris recommends maintaining battery charge by using a Polaris Bat- tery Tender charger or by charging about once a month to make up for normal self-discharge.

-

Page 123

Battery Battery Charging (Conventional Battery) 1. Remove the battery from the vehicle to prevent damage from leak- ing or spilled electrolyte during charging. See page 116. 2. Charge the battery with a charging output no larger than 1/10 of the battery’s amp/hr rating. -

Page 124

Battery Battery Charging (Sealed Battery) Always verify battery condition before and 1-2 hours after the end of charging. State of Voltage Charge 100% 12.8-13.0 volts 75%-100% 12.5-12.8 volts 50%-75% 12.0-12.5 volts 25%-50% 11.5-12.0 volts 0%-25% 11.5 volts or less Action specified on top of battery) None, check at 3 mos. -

Page 125: Camber And Caster

Follow the adjustment procedures exactly, or see your Polaris dealer for service. 1. Remove the upper headlight pod.

-

Page 126: Throttle Cable Freeplay

Throttle Body/Idle RPM Idle RPM is preset by the manufacturer. If the engine idle speed is not satisfactory, please see your Polaris dealer for adjustment. Throttle Cable Freeplay 1. Remove the four cover screws from the right han- dlebar control and remove the cover.

-

Page 127

6. If idle speed remains above or below the recommended setting (see specification pages), verify the correct gap. If gap is correct and idle speed is still not satisfactory, please see your Polaris dealer for ser- vice. 7. With the engine running, turn the handlebars fully to the left and right. -

Page 128: Cleaning And Storage

Do not allow these types of products to contact the vehicle. The best and safest way to clean your Polaris vehicle is with a garden hose and a pail of mild soap and water. 1. Use a professional-type washing cloth, cleaning the upper body first and the lower parts last.

-

Page 129: Polishing The Vehicle

Polishing the Vehicle Polaris recommends the use of common household aerosol furniture polish for polishing the finish on your Polaris vehicle. Follow the instructions on the container. Polishing Tips • Avoid the use of automotive products, some of which can scratch the finish of your vehicle.

-

Page 130

MAINTENANCE Cleaning and Storage Chrome Wheel Care (if equipped) Proper maintenance will protect chrome wheels from corrosion, pre- serve wheel life and ensure a “like new” appearance for many years. Chrome wheels exposed to road salt (or salt in the air in coastal areas) are more susceptible to corrosion if not properly cleaned. -

Page 131: Storage Tips

124. Stabilize the Fuel 1. Fill the fuel tank. 2. Add Polaris Carbon Clean Fuel Treatment or Polaris Fuel Stabilizer. Follow the instructions on the container for the recommended amount. Carbon Clean removes water from fuel systems, stabilizes fuel and removes carbon deposits from pistons, rings, valves and exhaust systems.

-

Page 132: Fluid Levels

6. If Polaris fuel system additive is not used, the fuel tank, fuel lines, and injectors should be completely drained of gasoline.

-

Page 133

Set the tire pressure and safely support the ATV with the tires slightly off the ground. Be sure the storage area is well ventilated. Cover the vehicle with a genuine Polaris cover. Do not use plastic or coated mate- rials. They do not allow enough ventilation to prevent condensation, and may promote corrosion and oxidation. -

Page 134: Transporting The Atv

MAINTENANCE Transporting the ATV Follow these procedures when transporting the vehicle. 1. Stop the engine. 2. Place the transmission in PARK. 3. Lock the parking brake. 4. Secure the fuel cap and oil cap. 5. Always tie the frame of the ATV to the transporting unit securely with suitable straps or rope.

-

Page 135: Troubleshooting

Dry out the PVT. See page 114. Inspect clutch seals for damage if repeated leaking occurs. See your Polaris dealer. Check for fouled plugs or foreign material in gas tank or fuel lines. See your dealer.

-

Page 136

Drain the fuel system and refuel Replace with fresh recommended fuel Inspect plugs and replace if necessary Inspect plugs, verify stop switch is on Immediately see your Polaris dealer Recharge the battery to 12.8 VDC See your dealer Solution Inspect, clean and/or replace spark… -

Page 137

Engine Pings or Knocks Possible Cause Poor quality or low octane fuel Incorrect ignition timing Incorrect spark plug gap or heat range Engine Runs Irregularly, Stalls or Misfires Possible Cause Fouled or defective spark plug(s) Worn or defective spark plug wires Incorrect spark plug gap or heat range Loose ignition connections Water present in fuel… -

Page 138: Engine Overheating

TROUBLESHOOTING Engine Stops or Loses Power Possible Cause Out of fuel Kinked or plugged fuel vent line Water is present in fuel Fouled or defective spark plug(s) Worn or defective spark plug wires Incorrect spark plug gap or heat range Loose ignition connections Low battery voltage Incorrect fuel…

-

Page 139: Polaris Products

Premium U-Joint Lube (14 oz./414 ml cartridge) 2871329 Dielectric Grease (Nyogel 2871326 Carbon Clean Plus 2870652 Fuel Stabilizer 2872189 DOT 4 Brake Fluid 2871956 Loctite 565 Thread Sealant 2859044 Polaris Battery Tender POLARIS PRODUCTS Engine Lubricant Coolant Additives / Miscellaneous Charger…

-

Page 140: Specifications

SPECIFICATIONS SPORTSMAN 550 Touring EPS Maximum Weight Capacity Dry Weight Front Rack/Storage Box Capacity 120 lbs. (54 kg) Rear Rack Capacity Hitch Tongue Weight Hitch Towing Rating Unbraked Trailer Towing Capacity* Overall Length Overall Width Overall Height Wheelbase Ground Clearance…

-

Page 141

SPORTSMAN 550 Touring EPS Lubrication System Transmission Type Front Suspension Rear Suspension Gear Reduction, Low Gear Reduction, Reverse Gear Reduction, High Drive Ratio, Front Drive Ratio, Rear Tire Type/Pressure, Front Tire Type/Pressure, Rear Brakes, Front/Rear Brake, Auxiliary Brake, Parking Headlight… -

Page 142

SPECIFICATIONS SPORTSMAN 850 Touring EPS Maximum Weight Capacity Dry Weight Front Rack/Storage Box Capacity 120 lbs. (54 kg) Rear Rack Capacity Hitch Tongue Weight Hitch Towing Rating Unbraked Trailer Towing Capacity* Overall Length Overall Width Overall Height Wheelbase Ground Clearance Minimum Turning Radius Fuel Capacity Engine Oil Capacity… -

Page 143

Altitude Meters 0-1800 (Feet) (0-6000) 1800-3700 (6000-12000) SPECIFICATIONS Pressurized Wet Sump Automatic PVT (Polaris Variable Transmission) In-Line H-L-N-R-P Dual a-arm, 9″ (22.9 cm) travel Dual a-arm with Rolled IRS, 10″ (25.4 cm) travel 5.034:1 4.508:1 2.367:1 3.818:1 3.7:1 Maxxis AT 26 x 8 — 14… -

Page 144: Declaration Of Conformity

Polaris Industries Inc., 2100 Hwy 55, Medina, MN 55340 U.S.A. Telephone 763-542-0500 We, Polaris Industries Inc., declare that the vehicles listed below conform to the essential health and safety requirements applicable to off-road all-terrain vehicles. APPLICABLE EUROPEAN DIRECTIVES 98/37/EC as amended (Machinery Directive)

-

Page 145: Warranty

WARRANTY LIMITED WARRANTY Polaris Sales Inc., 2100 Highway 55, Medina, MN 55340, gives a SIX MONTH LIM- ITED WARRANTY on all components of the Polaris All Terrain Vehicle (ATV) against defects in material or workmanship. Polaris also gives a one year limited warranty on the final drive chain (if equipped) for failure due to defects.

-

Page 146

WARRANTY COVERAGE AND EXCLUSIONS: LIMITATIONS OF WARRANTIES AND REMEDIES The Polaris limited warranty excludes any failures that are not caused by a defect in material or workmanship. This warranty does not cover accidental damage, normal wear and tear, abuse or improper handling. This warranty also does not cover any ATV that… -

Page 147

ATV. The exclusive remedy for breach of this warranty shall be, at Polaris’ exclusive option, repair or replacement of any defective materials, or com- ponents or products. THE REMEDIES SET FORTH IN THIS WARRANTY ARE THE ONLY REMEDIES AVAILABLE TO ANY PERSON FOR BREACH OF THIS WAR- RANTY. -

Page 148

HOW TO OBTAIN WARRANTY SERVICE If your ATV requires warranty service, you must take it to a Polaris dealer authorized to repair Polaris ATVs. When requesting warranty service you must present your copy of the Warranty Registration form to the dealer. -

Page 149

How to Get Service In the Country where your vehicle was purchased: Warranty or Service Bulletin repairs must be done by an authorized Polaris dealer. If you move or are traveling within the country where your vehicle was purchased, Warranty or Service Bulletin repairs may be requested from any authorized Polaris dealer who sells the same line as your vehicle. -

Page 150

How to Get Service If Purchased From A Private Party: If you purchase a Polaris product from a private citizen, to be kept and used outside of the country in which the vehicle was originally purchased, all warranty coverage will be denied. -

Page 151

This emissions limited warranty is in addition to the Polaris standard limited warranty for your vehicle. Polaris Industries Inc. warrants that at the time it is first purchased, this emissions-certified vehicle is designed, built and equipped so it conforms with applica- ble U.S. -

Page 152

Polaris dealer to perform any service that may be necessary for your vehicle. Polaris also recommends that you use only Pure Polaris parts. It is a potential violation of the Clean Air Act if a part supplied by an aftermarket parts manufacturer reduces the effectiveness of the vehicle’s emission controls. -

Page 153: Maintenance Log

MAINTENANCE LOG Present this section of your manual to your dealer each time your vehicle is serviced. This will provide you and future owners with an accurate log of maintenance and ser- vices performed. DATE MILES (KM) TECHNICIAN SERVICE PERFORMED / COMMENTS OR HOURS…

-

Page 154

MAINTENANCE LOG DATE MILES (KM) TECHNICIAN SERVICE PERFORMED / COMMENTS OR HOURS… -

Page 155: Index

4X4 Switch ….26, 37 Accessories ….129 Active Descent Control Fluid .

-

Page 156: Fluid Level

INDEX Fluid Active Descent Control ..88 ADC….88-89 Brake ….30 Demand Drive .

-

Page 157

Passenger Seat….34 Periodic Maintenance Chart ..76-79 Polaris Product List… . . 135 Polishing the Vehicle … 125 Power Steering . -

Page 158

INDEX Safety Warnings… . . 10-21 Protective Apparel ..12 Reverse Operation ..17 Skidding or Sliding .

ДОБРО ПОЖАЛОВАТЬ Мы признательны вам за приобретение продукции нашей компании и рады приветствовать во всемирном клубе любителей техники Polaris. Обязательно посетите наш веб-сайт www.brandtpolaris.ru чтобы узнать о последних новостях, новых продуктах, предстоящих событий, возможности карьерного

POLARIS, THE WAY OUT и SPORTSMAN являются зарегистрированными торговыми марками POLARIS Industries Inc. Copyright 2012 POLARIS Sales Inc. Весь материал в этом издании основывается на самой последней информации доступной на момент издания. Поскольку конструкция и качество выпускаемых нами

СОДЕРЖАНИЕ Введение . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Безопасность . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Органы управления, узлы и механизмы . . 26 Эксплуатация . . . . . . . . . . . . . . . . . . . . . . . . . 52 Система контроля вредных выбросов . . .

ВВЕДЕНИЕ На протяжении всего руководства пользователя появляются следующие сигнальные слова и символы. Когда используются эти слова и символы, речь идет о вашей безопасности и безопасности других. Прежде, чем читать данное руководство, ознакомьтесь с их значением. Предупредительный символ указывает

ВВЕДЕНИЕ ВНИМАНИЕ Не соблюдение инструкций приведенных ниже может привести к серьезным травмам или смерти. Квадроцикл Polaris не игрушка и при неправильной эксплуатации может представлять серьезную опасность. Специфика управления данным квадроциклом значительно отличается от других транспортных

ВВЕДЕНИЕ Идентификационные номера Запишите идентификационные номера квадроцикла и номер ключа зажигания в расположенной ниже таблице. Храните запасной ключ в надежном месте. Дубликат ключа зажигания выдается по заказу с использованием болванки для ключа Polaris (используйте номер вашего ключа)

Обучение по безопасности БЕЗОПАСНОСТЬ Прохождение обучения по безопасному вождению квадроцикла это приоритетное требование Polaris. Polaris настоятельно рекомендует всем пользователям квадроциклов пройти специальное обучение. При покупке квадроцикла в США, Ваш Дилер предоставит Вам информацию о

БЕЗОПАСНОСТЬ Экипировка водителя Соображения безопасности требуют, чтобы водитель мотовездехода был экипирован надлежащим образом. Надевайте специальную защитную одежду для комфорта и снижения опасности получения травмы. Шлем Защита глаз Длинные Рукава Перчатки Длинные Ботинки Шлем Ношение шлема

Экипировка водителя БЕЗОПАСНОСТЬ Защита глаз Не пользуйтесь обычными или солнцезащитными очками для защиты глаз. При движении на квадроцикле Polaris всегда носите защитные очки или шлем с защитным стеклом. Polaris рекомендует использовать защитное оборудование с маркировкой персональных средств

БЕЗОПАСНОСТЬ Предупредительные таблички ВНИМАНИЕ Пренебрежение предостережениями может привести к потере управления, повреждениям техники, личным травмам или смерти. Соблюдайте все правила безопасности, изложенные в данном разделе Руководства пользователя. Для правильной эксплуатации Вашего

БЕЗОПАСНОСТЬ Предупредительные таблички Бензин Бензин является легко воспламеняемой жидкостью и может быть взрывоопасным в определенных условиях. • Соблюдайте следующие предосторожности при заправке топливом. • Заправляйте квадроцикл топливом всегда в хорошо проветриваемом помещении, двигатель

БЕЗОПАСНОСТЬ Предупредительные таблички Защитная экипировка Движение на квадроцикле без специальной защитной экипировки может привести к личным травмам. Водитель и пассажир во время движения должны находится в специальных шлемах и защитных очках. Перевозка пассажира Не перевозите пассажира пока у

БЕЗОПАСНОСТЬ Предупредительные таблички Движение по дороге с асфальтовым покрытием, выезд на тротуар, подъездные пути, места стоянки Вождение по мощеным поверхностям может отрицательным образом сказаться на управлении квадроциклом и привести к потери контроля, аварии и/или травме. Не выезжайте на

БЕЗОПАСНОСТЬ Предупредительные таблички Отпускание руля, езда без надежного контакта ног с подножками Снятие даже одной руки с рукоятки руля или снятие ноги с подножки уменьшает Вашу способность контролировать мотовездеход, приводит к потере равновесия и падению с мотовездехода. Если нога водителя

БЕЗОПАСНОСТЬ Предупредительные таблички Неправильная техника движения вверх по склону Неправильный подъем на склоны может стать причиной потери управления или опрокидывания. При движении вверх по склону действуйте в соответствии с рекомендациями в настоящем Руководстве. См. стр. 65. Всегда

БЕЗОПАСНОСТЬ Предупредительные таблички Вынужденная остановка на склоне. Скатывание по склону. Остановка скатывание, неверное начало движение на склоне могут привести к перевороту квадроцикла. • Всегда поддерживайте постоянную скорость при движении вверх по склону. • Всегда включайте режим 4X4 ADC

БЕЗОПАСНОСТЬ Предупредительные таблички Движение по скользкой местности Пренебрежение правилами безопасности во время езды по чрезмерно крутым, сыпучим или скользким склонам, это может привести к потере управления, опрокидыванию мотовездехода или к потере сцепления с грунтом. Не используйте

БЕЗОПАСНОСТЬ Предупредительные таблички Эксплуатация мотовездехода с нерекомендованным типом шин или неравномерно накачанными шинами Эксплуатация мотовездехода с нерекомендованными или неисправными шинами может привести к потере управления и травмам и даже смерти. Всегда используйте только

БЕЗОПАСНОСТЬ Предупредительные таблички Движение по глубокой воде Во время движения по глубокой воде или быстром водном потоке возможно всплывание колес, что приведет утрате контроля над мотовездеходом и в результате – несчастному случаю. Никогда не передвигайтесь на мотовездеходе по быстрым

следуйте инструкциям в настоящем руководстве. См. стр. 62. 20

21

БЕЗОПАСНОСТЬ Предупредительные таблички Вождение по замерзшим водоемам Вождение по замерзшим водоемам может привести к внезапному пролому льда, что в свою очередь станет причиной травмы или гибели в случае ухода под лед. Никогда не двигайтесь по замершим водоемам и льду, пока не убедитесь что лед

БЕЗОПАСНОСТЬ Предупредительные таблички Эксплуатация неисправного мотовездехода Эксплуатация неисправного мотовездехода приводит к авариям, несчастным случаям, травмам и гибели людей. Если Вы попали в ДТП, покажите мотовездеход дилеру, так как машине могут быть нанесены серьезные повреждения.

БЕЗОПАСНОСТЬ Предупредительные таблички и их расположение На корпусе мотовездехода прикреплены таблички с важной информацией, касающейся Вашей безопасности. Внимательно прочитайте таблички и следуйте содержащимся в них инструкциям. Если содержание табличек на Вашем мотовездеходе отличается от того,

БЕЗОПАСНОСТЬ Предупредительные таблички и их расположение Общие предупреждения ВНИМАНИЕ Неправильная эксплуатация мотовездехода может привести к СЕРЬЕЗНОЙ ТРАВМЕ, НЕСЧАСТНОМУ СЛУЧАЮ или ЛЕТАЛЬНОМУ ИСХОДУ ВСЕГДА ИСПОЛЬЗУЙТЕ ЗАЩИТНЫЙ ШЛЕМ И ЗАЩИТНУЮ ОДЕЖДУ ДЛЯ ВОДИТЕЛЯ И ПАССАЖИРА ЗАПРЕЩАЕТСЯ

БЕЗОПАСНОСТЬ Предупредительные таблички и их расположение Предупреждение по перевозке пассажира/общего характера ВНИМАНИЕ Безопасность пассажира Для того, чтобы снизить риск ТРАВМ или даже СМЕРТИ НИКОГДА НЕ ПЕРЕВОЗИТЕ БОЛЕЕ ОДНОГО ПАССАЖИРА НИКОГДА НЕ ЭКСПЛУАТИРУЙТЕ КВАДРОЦИКЛ НАХОДЯСЬ ПОД

БЕЗОПАСНОСТЬ Предупредительные таблички и их расположение Багажная площадка/ Предупреждающая Предупреждение на крышке вари- Предупреждение по фаркопу Предупреждающая табличка по багажной площадке ВНИМАНИЕ • НЕ БУКСИРУЙТЕ ГРУЗ, ПРИКРЕПИВ ЕГО К БАГАЖНЫМ ПЛОЩАДКАМ ИЛИ БАМПЕРУ Возможно повреждение или

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Переключатели Переключатель фар 2×4 E km 88:88 Mode/Reverse Override ПереключаВыключатель двигателя Переключатель 4X4 F RPM Trip 1 mi Замок зажигания Кнопка Mode/Кнопка Оverride На данном квадроцикле присутствует система ограничения скорости при движение задним

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Переключатели Выключатель двигателя Чтобы быстро остановить работу двигателя переведите выключатель вправо или влево в положение ВЫКЛ (OFF). Перед запуском двиВЫКЛ RUN ВЫКЛ гателя переведите выключатель в положение RUN (ВКЛ.). Запуск и работа двигателя

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Рычаг акселератора ВНИМАНИЕ Эксплуатация мотовездехода с неисправным приводом дроссельной заслонки может привести к несчастному случаю, травмам или гибели. Эксплуатация мотовездехода с неисправным приводом дроссельной заслонки ЗАПРЕЩЕНА. В случае неисправности

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Рычаг тормоза ВНИМАНИЕ Эксплуатация мотовездехода с «проваливающимся» рычагом тормоза ЗАПРЕЩЕНА. Никогда не управляйте мотовездеходом с излишне «мягким» рычагом тормоза. В случае неисправности обратитесь к Дилеру для проведения ремонта. Передние и задние тормоза

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Главный тормозной цилиндр/Тормозная жидкость ВНИМАНИЕ Переполнение главного цилиндра может стать причиной подклинивания или полной блокировки колес, что может привести к травмам или несчастному случаю. Поддерживайте необходимый уровень тормозной жидкости. Не

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Стояночный тормоз Включение стояночного тормоза 1. Включите парковочную передачу. 2. Два или три раза надавите на тормозной рычаг и удерживайте его. 3. Сдвиньте замок стояночного тормоза вперед. 4. Отпустите рычаг тормоза. 5. Чтобы снять машину со стояночного

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Дополнительный ножной тормоз ВНИМАНИЕ Не спускайтесь с холма задним ходом. Резкое включение дополнительного тормоза при спуске с холма может привести к опрокидыванию мотовездехода, причинить травмы водителю или стать причиной его гибели. Будьте осторожны при

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Рычаг выбора режима трансмиссии Рычаг выбора режима Передача трансмиссии располоРукоятка жен с правой стороны мотовездехода. H Повышающая передача L: Понижающая передача N: Нейтраль R: Задний ход P: Парковка Для того чтобы переключить передачу, полностью

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Электроусилитель рулевого управления (EPS) Если на Вашем квадроцикле установлен электроусилитель рулевого управления, он включается в работа сразу же при включении зажигания. Электроусилитель продолжает функционировать в любой момент при включенном двигателе. На

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Топливный бак Заправляйте квадроцикл топливом всегда в хорошо проветриваемом помещении, двигатель должен быть выключен. Заправляйте квадроцикл на ровной поверхности. Снимите крышку топливного бака и залейте топливо. Используйте бензин с октановым числом не менее

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Передний багажный короб Для доступа под багажное отделение — откройте его. 1. Откройте фиксаторы и откройте крышку. 2. Ослабьте анкерные фиксаторы багажного отделения. 3. Закройте крышку отделения и приподнимите незакрепленную Фиксаторы Фиксаторы багажного часть

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Система полного привода Система полного привода ADC 4X4 управляется переключателем 4X4. Режим ADC 4X4 Когда включен режим ADC 4X4, система ADC обеспечивает торможение двигателем всех четырех колес на спуске. Всегда включайте режим 4X4 ADC перед спуском или

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Система полного привода Включение режима 4X4 Во время движения мотовездехода переключатель 4X4 можно включать и выключать. Электронная система управления блокирует включение полного привода до тех пор, пока обороты двигателя не превысят 3100 об/мин. Режим полного

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Система ADC Система ADC обеспечивает торможение двигателем всех четырех колес на спуске. Всегда включайте режим 4X4 ADC перед спуском или подъемом на холм. Включение системы ADC Система ADC включается при совпадении всех четырех условий: • Выключатель должен быть

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор ПРИМЕЧАНИЕ:Высокое давление воды может повредить элементы квадроцикла. Мойте квадроцикл вручную с использованием слабого мыльного раствора. Некоторые химические составы при попадании на цифровой прибор пластик или фары повредят эти элементы. Не

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Комбинированный Цифровой/Аналоговый прибор Контрольные лампы Лампа Индикатор Скорость Условие При выборе стандартного режима, скорость будет показана в милях в час. При выборе метрического режима, скорость будет показана в км/ч. Перегрев Эта лампа

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Комбинированный Цифровой/Аналоговый прибор Информационный центр Информационный дисплей расположен в центральной части цифрового прибора Все сегменты информационного центра включаться на несколько секунд при включении зажигания. В случае, если

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Комбинированный Цифровой/Аналоговый прибор Информационный центр 1. Индикатор передачи — Указывает текущий режим трансмиссии. H = Повышающая L = Понижающая N = Нейтраль R = Задний ход P = Парковочная — = Ошибка переключения 2. Уровень топлива —

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Комбинированный Цифровой/Аналоговый прибор Информационный центр Кнопка Override при кратковременных дискретных нажатиях функционирует как кнопка MODE. Для использования переключателя Override, как MODE, рычаг КПП не должен находится в режиме

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Комбинированный Цифровой/Аналоговый прибор Информационный центр Часы Подсказка:Часы сохраняют настройки до тех пор, пока аккумулятор не будет отсоединен или разряжен. 1. Переведите ключ в положение «ON». Используйте кнопку MODE для переключения

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Комбинированный Цифровой/Аналоговый прибор Информационный центр Программируемые сервисные интервалы Когда наработка двигателя будет соответствовать запрограммированному сервисному интервалу, на дисплее появится значок гаечного ключа, который будет

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Комбинированный Цифровой/Аналоговый прибор Информационный центр Коды ошибок Предполагаемый Номер кода Индикация ошибок возномер параметра неисправности можна только когда активен индикатор CHECK ENGINE или он включается-выключается в течение

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Расшифровка диагностических кодов ошибок Размыкание цепи: Имеет место обрыв в цепи. Замыкание на “массу”: Имеет место замыкание на массу между ECU и элементом нагрузки. Межпроводное замыкание цепи: Имеет место замыкание между двумя проводами цепи.

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Расшифровка диагностических кодов ошибок Диагностические коды SPORTSMAN Touring 550 Элемент Моторчик холостого хода Цепь стартера Цепь системы полного привода Питание системы Состояние SPN 520193 FMI 5 520193 11 1321 520207 168 168 520194 520194

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Расшифровка диагностических кодов ошибок Диагностические коды SPORTSMAN Touring 850 Элемент Датчик положения дросселя Состояние Повышенное напряжение Пониженное напряжение Датчик температуры двигателя Повышенное напряжение Пониженное напряжение

ОРГАНЫ УПРАВЛЕНИЯ, УЗЛЫ И МЕХАНИЗМЫ Цифровой прибор Расшифровка диагностических кодов ошибок Диагностические коды SPORTSMAN Touring 850 Элемент SPN FMI 520208 520208 520208 520207 520207 520207 168 168 520194 520194 520194 520194 520203 520203 520203 520211 520211 5 3 4 5 3 4 3 4 3 4 2 7 5 3 4 3 4

ЭКСПЛУАТАЦИЯ ВНИМАНИЕ Пренебрежение предостережениями может привести к потере управления, повреждениям техники, личным травмам или смерти. Соблюдайте все правила безопасности, изложенные в данном разделе Руководства пользователя. Обкатка Периодом обкатки нового мотовездехода Polaris считаются

Обкатка ЭКСПЛУАТАЦИЯ Обкатка двигателя и ходовой части 1. Залейте топливо в бак. См. стр. 37. Соблюдайте следующие предосторожности при заправке топливом. 2. Проверьте уровень масла при помощи щупа. См. стр. 83. При необходимости долейте масло до требуемого уровня. 3. Первое время перемещайтесь

ЭКСПЛУАТАЦИЯ Перечень предварительных проверок Пренебрежение проверкой состояния мотовездехода перед эксплуатацией и нарушение технологии обслуживания мотовездехода повышает вероятность возникновения аварий и несчастных случаев. Обязательно проверяйте состояние Вашего мотовездехода перед каждой

ЭКСПЛУАТАЦИЯ Практика безопасной эксплуатации 1. Перед началом эксплуатации пройдите курс по безопасному вождению квадроциклов. См. стр. 7. 2. Не позволяйте детям младше 16 лет использовать данный мотовездеход. Не позволяйте людям с ограниченными физическими и умственными способностями управлять

ЭКСПЛУАТАЦИЯ Изучите местность Перед началом эксплуатации квадроцикла изучите все местные правила и законы, регламентирующие движение на подобного рода технике. Относитесь ответственно к природе. Выясните где находятся самые безопасные места для катания. Помогите сохранить трассы открыты для

Запуск двигателя ЭКСПЛУАТАЦИЯ 1. Установите мотовездеход на ровной площадке. 2. Включите парковочную передачу. 3. Включите стояночный тормоз. Подсказка:Система блокировки запуска двигателя сработает, при попытке запустить двигатель в режиме движения или отпущенном рычаге тормоза. 4. Сядьте на

ЭКСПЛУАТАЦИЯ Вождение 1. Эксплуатируйте мотовездеход только в специальной защитной экипировке См. стр. 8. 2. Выполните предэксплуатационные проверки. См. стр. 56. 3. Включите парковочную передачу. 4. Включите стояночный тормоз. 5. Сядьте на мотовездеход с левой стороны 6. Сядьте на квадроцикл, обе

Поворот ЭКСПЛУАТАЦИЯ Оба задних колеса имеют одинаковую скорость вращения. Это означает, что при повороте наружное колесо проходит большее расстояние по сравнению с внутренним при повороте и внутренняя шина слегка проскальзывает. 1. Двигайтесь на малой скорости. 2. Не делайте резких поворотов и

ЭКСПЛУАТАЦИЯ Езда с пассажиром 1. Не перевозите ребенка младше 12 лет в качестве пассажира. Убедитесь, что пассажир достаточно высокий, чтобы сидя на сиденье, надежно держаться за рукоятки и упираться ногами в подножки. 2. Не перевозите пассажира пока у Вас не появится опыт эксплуатации не менее 2

Езда с пассажиром ЭКСПЛУАТАЦИЯ 11. Согласуйте условия поездки с пассажиром, не опираясь только на собственные ощущения. Избегайте резких маневров, вследствие которых пассажир может выпасть. 12. Не двигайтесь поперек склона вместе с пассажиром. См. стр. 66. 13. Пассажир всегда должен сидеть на

ЭКСПЛУАТАЦИЯ Движение по скользким поверхностям Если Вы двигаетесь по скользким грунтам (грязь, песок, снег и т.д.) следуйте указаниям: 1. Старайтесь избегать движения по такому типу покрытия. 2. Снизьте скорость при подъезде к скользкому участку. 3. Включите режим 4X4 при подъезде к скользкому

Движение вверх по склону ЭКСПЛУАТАЦИЯ 15° максимум Тормозной эффект и управляемость сильно изменяются при движении по склону. Неправильное движение по склону может привести к потере управления. При движении по склону следуйте инструкциям: 1. Всегда включайте режим 4X4 ADC перед спуском или подъемом

ЭКСПЛУАТАЦИЯ Движение поперек склона Не рекомендуется двигаться вдоль склона. Неправильное движение по склону может привести к потере управления. Старайтесь на двигаться вдоль склона. В случае, если Вам необходимо проехать поперек склона: 1. Двигайтесь на малой скорости. 2. Движение поперек склона

ЭКСПЛУАТАЦИЯ Спуск с холма 15° максимум Двигаясь вниз по склону, соблюдайте следующие правила: 1. Перед спуском внимательно исследуйте рельеф местности. 2. Всегда включайте режим 4X4 ADC перед спуском или подъемом на холм. См. стр. 41. 3. При спуске со склона всегда включайте переднюю передачу. Не

ЭКСПЛУАТАЦИЯ Разворот на склоне (K-образный разворот) Если двигатель мотовездехода заглох при движении вверх по склону, не спускайтесь на нем задним ходом! Развернитесь, используя K-образный разворот. 2.4 м 68

ЭКСПЛУАТАЦИЯ Разворот на склоне (K-образный разворот) 1. Остановитесь и включите стояночный тормоз, перенеся центр тяжести тела в направлении, к вершине склона. 2. Всегда включайте режим 4X4 ADC перед спуском или подъемом на холм. См. стр. 41. 3. Оставайтесь на передней передаче и остановите

ЭКСПЛУАТАЦИЯ Преодоление водных преград Мотовездеход Polaris может двигаться по водоему с максимальной глубиной, при которой подножки находятся выше уровня воды. При пересечении водной преграды соблюдайте следующие правила: 1. Определите глубину и направление потока. Максимальная глубина 2.

Преодоление препятствий ЭКСПЛУАТАЦИЯ Следуйте инструкциям при преодолении препятствий: 1. Изучите все препятствия на местности перед началом эксплуатации квадроцикла там. 2. Научитесь «читать» характер местности. Постоянно будьте готовы к появлению препятствий в виде бревен, камней, свисающих веток

ЭКСПЛУАТАЦИЯ Движение задним ходом При движении задним ходом соблюдайте следующие правила: 1. Всегда проверяйте наличие препятствий или людей позади мотовездехода. Будьте осторожны, пассажир может загораживать обзор. 2. Всегда старайтесь избегать движения задним ходом вниз по склону. 3. Двигайтесь

Парковка на склоне ЭКСПЛУАТАЦИЯ При возможности избегайте стоянки на склоне. Если это неизбежно, соблюдайте следующие правила: 1. Выключите двигатель. 2. Включите парковочную передачу. 3. Включите стояночный тормоз. 4. Заблокируйте задние колеса при помощи какого-либо предмета со стороны, которая

ЭКСПЛУАТАЦИЯ Перевозка грузов ВНИМАНИЕ Нарушение правил перевозки груза приводит к потере контроля над машиной и ухудшению эффективности торможения, что, как правило, заканчивается серьезными травмами, увечьями или гибелью людей. Соблюдайте правила техники безопасности при транспортировке грузов:

Перевозка грузов ЭКСПЛУАТАЦИЯ 1. Никогда не превышайте грузоподъемность Вашего мото2:3 вездехода, указанную на 1:3 предупреждающих табличках и в спецификациях в руководстве пользователя. 2. Груз должен быть равномерно распределен (1/3 веса на передней багажной площадке и 2/3 веса на задней багажной

ЭКСПЛУАТАЦИЯ Перевозка грузов Буксировка грузов Цепляйте прицеп только за специальное прицепное устройство. Снимайте фаркоп, если не планируете ездить с прицепом. При буксировке прицепа с грузом, уменьшите вес груза на задней багажной площадке на величину нагрузки на фаркоп. • Общий вес веса груза

ЗАЩИТА ОКРУЖАЮЩЕЙ СРЕДЫ Система шумоподавления Самостоятельное изменение конструкции двигателя, системы впуска и системы выпуска выхлопных газов ЗАПРЕЩЕНО! Уровень шума соответствует требованиям 40 CFR 205, а также местным нормам. Система контроля вредных выбросов Картер двигателя выполнен по

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Регламент технического обслуживания Надлежащий уход и обслуживание сохранят Ваш мотовездеход в наилучшем состоянии. Проверка, затяжка, очистка, замена при необходимости. При необходимости замены деталей используйте только подлинные компоненты POLARIS, поставляемые дилером.

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Регламент технического обслуживания Расшифровка символов Символ Описание ► Выполняйте эти операции более часто для мотовездеходов, которые эксплуатируются в тяжелых условиях. E Обслуживание компонентов влияющих на чистоту отработавших газов. D Обращайтесь авторизованному

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Регламент технического обслуживания Необходимо производить операции в соответствие с рекомендациями по периодичности проведения, в зависимости от того, что наступит ранее. Элемент Периодичность (что наступит ранее) Мили (KM) Часы Период Рулевое управление — перед выездом —

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Регламент технического обслуживания Элемент Периодичность (что наступит ранее) Мили (KM) Часы Период D Тросик привода дросселя/ E Выключатель ETC 50 ч 6 Месяцев E Впускной патрубок 50 ч 6 Месяцев Приводной ремень. 50 ч 6 Месяцев Система охлаждения 50 ч 6 Месяцев ► Радиатор

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Рекомендации по смазке Проверяйте и смазывайте все компоненты через интервалы, указанные в регламенте ТО, стр. 78. Позиции, не перечисленные в регламенте, через общие интервалы смазки аналогичных узлов. А-образные рычаги смазываются на заводе при установке и не нуждаются в

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Масло двигателя Требования к моторному маслу Polaris рекомендует использовать масло Polaris PS-4 PLUS Performance Synthetic 2W-50 для данного двигателя. См таблицу на стр 82. При использовании масел других производителей, гарантия POLARIS теряет силу. Используйте только

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Масло двигателя Замена масла и фильтра См таблицу на стр 82. Меняйте масло в соответствии с интервалами, указываемыми в таблице регламента технического обслуживания, начинающейся на стр. 78. При замене масла необходимо заменять масляный фильтр. Сливная пробка 550 Перед

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Масло двигателя Замена масла и фильтра 9. Расположите ветошь под 550 850 масляным фильтром. С помощью специального ключа открутите фильтр. Вращайте фильтр против часовой стрелки для того, чтобы его снять. 10. Используя чистую ткань, очистите посадочное место фильтра. 11.

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Трансмиссионное Масло Polaris рекомендует использовать масло POLARIS AGL PLUS для данной трансмиссии. См таблицу на стр 82. Выполняйте периодическое техническое обслуживание в соответствии с интервалами, указываемыми в таблице регламента технического обслуживания,

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Трансмиссионное масло Замена масла 1. Снимите подножку. 2. Расположите емкость для использованного масла под сливной пробкой. Снимите сливную пробку. Полностью слейте масло. 3. Очистите и установите сливную пробку. Затяните в соответствие со спецификацией. 4. Снимите

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Передний редуктор (Жидкость Demand Drive) См таблицу на стр 82. Выполняйте периодическое техническое обслуживание в соответствии с интервалами, указываемыми в таблице регламента технического обслуживания, начинающейся на стр. 78. На стр. 133 указаны каталожные номера

Жидкость ADC ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Проверяйте и Обратитесь к Дилеру для замены масла в коробке передач в соответствии с интервалами, указываемыми в таблице регламента технического обслуживания, начинающейся на стр. 78. Polaris рекомендует использовать жидкость POLARIS Demand Drive Plus Fluid в

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Жидкость ADC Замена жидкости 1. Расположите технику на Колпачок ровной поверхности. Перед штуцера началом процедуры, оставьте прокачки квадроцикл без движения как Винт минимум на 30 минут. штуцера прокачки 2. Тщательно очистите резервуар и штуцер клапана прокачки системы

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Масло заднего редуктора См таблицу на стр 82. Выполняйте периодическое техническое обслуживание в соответствии с интервалами, указываемыми в таблице регламента технического обслуживания, начинающейся на стр. 78. На стр. 133 указаны каталожные номера продуктов POLARIS.

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Электроусилитель руля Если Ваш квадроцикл оснащен Часто очищайте электроусилителем рулевого управления производите очистку указанных областей как можно чаще для обеспечения охлаждения устройства. Тщательно очищайте. Рулевое управление Необходимо периодически проверять

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Система охлаждения Расширительный бачок Уровень охлаждающей жидкости в расширительном бачке можно видеть из-под крыла переднего правого колеса. Заливная горловина расширительного бачка находится под передней багажной площадкой. См. стр. 38. 1. Проверьте уровень жидкости в

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Система охлаждения Радиатор Чтобы система охлаждения сохраняла способность эффективного охлаждения двигателя, охлаждающую жидкость необходимо менять раз в два года. Заменяйте охлаждающую жидкость всегда, когда система охлаждения сливается для проведения технического

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Тормозная система Ручной тормоз Передние и задние тормоза — дисковые, с гидравлическим приводом, управляются одним рычагом на рукоятке руля. Тормоза— саморегулирующиеся. При нормальном функционировании диафрагма втягивается в бачок при понижении уровня жидкости. Если

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ Схождение Используйте процедуру для проверки схождения передних колес. Рекомендуемое схождение: -(6-12) мм (расхождение). ВНИМАНИЕ!Неверная регулировка схождения может привести к повреждениям или смерти. Не производите регулировку самостоятельно. Регулировку должен