Думаю одной из главных тем в любом сообществе которое ведётся по узкой специальности, а в нашем случае Almera N15, нужно иметь максимальную информацию по ремонту и обслуживанию. Так вот, небольшая подборочка полезного чтива:

1) Nissan Almera N15 Service Manual

Руководство по ремонту и техобслуживанию Nissan Almera N15 содержит подробное и полное описание ремонта и диагностики всех агрегатов автомобиля Ниссан Алмера, включая кузовные размеры для вытяжки кузова, подробный ремонт АКПП и МКПП, подробные электрические схемы, моменты затяжек, процесс сборки и разборки двигателя и других агрегатов и узлов, ремонт сцепления, рулевого управление, кондиционера, всех электрических устройств и блоков управления, необходимый специальный инструмент, а так же другая информация.

Ссылка на ЯндексДиск (архив .zip) Размер 152мб. Файлы в формате .pdf

Пример из одного PDF файла

2) Инструкция по эксплуатации Almera N15.

Это стандартная книженция которая выдавалась счастливому обладателю при покупке нового автомобиля в те далёкие годы, обычно шло в комплекте с сервисной книжкой и прочими «фантиками» =)

Ссылка на ЯндексДиск (формат .pdf) Размер 7,6мб.

3) Родная инструкция по ремонту и обслуживанию.

Стандартная инструкция которая шла вместе с автомобилем при покупке. Здесь собраны основные данные по машине, сколько чего заливать, как менять и когда))

Качество копирования не очень, но всё равно читается =)

Ссылка на ЯндексДиск (формат .pdf) Размер 90мб.

4) Мультимедийное руководство по ремонту Almera N15

• Секреты эксплуатации

• Детальное описание операций

• Более 500 иллюстраций

• Цветные электросхемы

В новой серии представлены руководства по ремонту, техническому обслуживанию и эксплуатации самых популярных в России на сегодняшний день зарубежных легковых автомобилей.В этих руководствах на основе обширного иллюстрированного материала автовладельцы, автомеханики средних и небольших автомастерских найдут всю необходимую для ремонта информацию по различным узлам и системам, познакомятся с особенностями эксплуатации и технического обслуживания. Издания снабжены цветными электросхемами.

Ссылка на ЯндексДиск (формат .rar) В разархивированном варианте образ диска .ISO) Размер 260мб.

з.ы. возможно будет продолжение =)

Руководство по эксплуатации, техническому и ремонту автомобиля Ниссан Альмера первого поколения (код N15) с четырехцилиндровыми бензиновыми двигателями объемом 1.4 литра (GA14DE), 1.5 литра (GA15DE), 1.6 литра (GA16DE) и 2.0 литра (SR20DE), а также с дизельными моторами объемом 2.0 литра (CD20, CD20E). Коробки передач описываются механические RS5F30A, RS5F31A и RS5F32A, а также автоматические.

Смотрите этот мануал на: болгарском, белорусском, украинском, сербском, хорватском

Руководство по эксплуатации

Приборы управления

Введение в руководство по эксплуатации

Описание панели управления

Сигнальные и контрольные лампочки и зуммеры

Сигнальная лампа противоугонной системы NATS

Полный список статей этой категории »

Подготовка к движению

Ключ зажигания

Дверные замки

Отпирание капота

Замок вещевого ящика

Полный список статей этой категории »

Отопитель, кондиционер и аудио

Центральные и боковые сопла вентилятора

Ручки управления кондиционером и отопителем

Работа обогревателя

Работа кондиционера

Полный список статей этой категории »

Запуск двигателя и вождение

Обкатка нового автомобиля

Перед запуском двигателя

Меры предосторожности при запуске двигателя и движении

Меры безопасности при движении

Полный список статей этой категории »

Техническое обслуживание

Общий уход за автомобилем

Защита кузова от коррозии

Меры предосторожности при выполнении технического ухода

Схема расположения точек обслуживания

Полный список статей этой категории »

Техническая информация

Рекомендуемое топливо, смазочные жидкости и заправочные объемы

Рекомендуемые типы смазочных жидкостей

Смазочная жидкость и хладагент воздушного кондиционера

Основные характеристики двигателей

Полный список статей этой категории »

Силовой агрегат

Ремонт двигателя

Общие указания по ремонту двигателя

Стандартные и специальные инструменты и приспособления

Измерение компрессии в цилиндрах

Масляный поддон — снятие и установка

Полный список статей этой категории »

Система смазки

Нанесение герметика в качестве «жидкой прокладки»

Специальные инструменты и приспособления

Схема смазочной системы

Проверка давления масла

Полный список статей этой категории »

Система охлаждения

Схема системы охлаждения

Водяной насос — снятие, проверка и установка

Термостат — снятие, установка и проверка

Выходной патрубок — проверка и установка

Полный список статей этой категории »

Система управления (бензин)

Общие меры предосторожности

Специальные инструменты и приспособления

Электрическая принципиальная схема

Структурная схема системы управления двигателем

Полный список статей этой категории »

Система управления (дизель)

Общие меры предосторожности

Специальные инструменты и приспособления

Электрическая принципиальная схема

Структурная схема системы управления двигателем

Полный список статей этой категории »

Система питания и выхлопа

Привод дроссельной заслонки — устройство

Регулировка троса привода дроссельной заслонки

Управление подачей топлива в двигателе CD20E

Топливный бак и топливный насос — устройство

Полный список статей этой категории »

Трансмиссия

Сцепление

Общие меры предосторожности

Специальные инструменты и приспособления

Регулировка педали сцепления

Удаление воздуха из гидравлического привода сцепления

Полный список статей этой категории »

Механическая коробка передач

Специальные и стандартные инструменты и приспособления

Замена сальников МКПП

Проверка выключателей

Снятие и установка коробки передач

Полный список статей этой категории »

Автоматическая коробка передач

Специальные инструменты и приспособления

Механизм переключения передач

Конструкция автоматической коробки передач

Проверка рабочей жидкости

Полный список статей этой категории »

Шасси

Передняя подвеска

Общие замечания

Специальные и стандартные инструменты и приспособления

Проверка деталей подвески на автомобиле

Устройство передней подвески

Полный список статей этой категории »

Задняя подвеска

Общие замечания о ремонте задней подвески

Специальные и стандартные инструменты и приспособления

Устройство задней подвески

Устройство ступицы заднего колеса

Полный список статей этой категории »

Рулевое управление

Общие указания по ремонту рулевого управления

Специальные и стандартные инструменты и приспособления

Рулевое колесо и рулевая колонка — устройство

Проверка рулевого управления на автомобиле

Полный список статей этой категории »

Тормозная система

Общие указания по ремонту тормозной системы

Стандартные инструменты и приспособления

Обслуживание тормозной системы

Удаление воздуха из гидравлического привода

Полный список статей этой категории »

Кузов

Отопление и кондиционирование

Общие меры предосторожности

Правила работы с компрессором кондиционера

Правила работы с соединениями

Специальные инструменты и приспособления

Полный список статей этой категории »

Система безопасности

Указания по работе с подушками безопасности

Расположение компонентов в системе с двумя подушками безопасности

Блок управления — снятие и установка

Механические натяжители ремней безопасности — снятие к установка

Полный список статей этой категории »

Элементы кузова

Зажимы и фиксаторы

Снятие и установка бамперов

Регулировка петель и замков

Наружное зеркало заднего вида — снятие

Полный список статей этой категории »

Электрооборудование

Оборудование и приборы

Электрические разъемы

Стандартные реле

Список сокращений, используемых на схемах

Принципиальная схема подачи питания к потребителям

Полный список статей этой категории »

Силовые устройства

Защита электрических цепей

Аккумуляторная батарея

Устройство стартера

Стартер — снятие, проверка и сборка

Полный список статей этой категории »

Отправить эту информацию вашим друзьям:

программа для ремонта автомобилей . Купить отзывы авито: накрутка отзывов авито.

Ссылка в разных форматах на этот раздел

TEXTHTMLBB Code

Руководство на английском языке по техническому обслуживанию и ремонту автомобиля Nissan Almera Classic серии B10.

- Автор: —

- Издательство: Nissan Motor Co., Ltd.

- Год издания: 2006

- Страниц: —

- Формат: PDF

- Размер: 74,1 Mb

Руководство на английском языке по техническому обслуживанию и ремонту автомобиля Nissan Almera серии N16.

- Автор: —

- Издательство: Nissan Motor Co., Ltd.

- Год издания: 2001

- Страниц: —

- Формат: PDF

- Размер: 101,2 Mb

Руководство на английском языке по техническому обслуживанию и ремонту автомобиля Nissan Almera серии N16.

- Автор: —

- Издательство: Nissan Motor Co., Ltd.

- Год издания: 2003

- Страниц: —

- Формат: PDF

- Размер: 118,0 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобиля Nissan Almera серии N15 1995-2000 годов выпуска.

- Автор: —

- Издательство: Nissan Motor Co., Ltd.

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 211,9 Mb

Руководство на английском языке по техническому обслуживанию и ремонту автомобилей Nissan Almera/Latio/Sunny/Versa 2011-2012 годов выпуска.

- Автор: —

- Издательство: Motorist

- Год издания: —

- Страниц: 2747

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобиля Nissan Almera 1996 года выпуска.

- Автор: —

- Издательство: Nissan Europe

- Год издания: 1995

- Страниц: 318

- Формат: PDF

- Размер: 67,0 Mb

Руководство по эксплуатации и техническому обслуживанию автомобиля Nissan Almera 2013 года выпуска.

- Автор: —

- Издательство: Nissan International SA

- Год издания: 2012

- Страниц: 172

- Формат: PDF

- Размер: 3,1 Mb

Руководство по эксплуатации и техническому обслуживанию автомобиля Nissan Almera 1996 года выпуска.

- Автор: —

- Издательство: Nissan Europe

- Год издания: 1995

- Страниц: 149

- Формат: PDF

- Размер: 7,7 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan Almera Classic с 2005 года выпуска с бензиновым двигателем объемом 1,6 л.

- Автор: —

- Издательство: Третий Рим

- Год издания: —

- Страниц: 344

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan Almera серии N16 2000-2006 годов выпуска с бензиновыми двигателями объемом 1,5/1,8 л.

- Автор: —

- Издательство: АртСтиль

- Год издания: 2007

- Страниц: 424

- Формат: PDF

- Размер: 114,8 Mb

Руководство по техническому обслуживанию и ремонту автомобиля Nissan Almera 1995-1999 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Атласы автомобилей

- Год издания: —

- Страниц: 190

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобиля Nissan Almera Classic серии с 2006 года выпуска с бензиновым двигателем объемом 1,6 л.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 302

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Nissan Almera Classic.

- Автор: —

- Издательство: MoToR

- Год издания: —

- Страниц: 270

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan Almera с 2000 года выпуска с бензиновыми двигателями объемом 1,5/1,8 л.

- Автор: —

- Издательство: Арго-Авто

- Год издания: —

- Страниц: 264

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобиля Nissan Almera Classic серии B10 2006-2012 годов выпуска с бензиновым двигателем объемом 1,6 л.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 374

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan Almera серии G15 с 2013 года выпуска с бензиновым двигателем объемом 1,6 л.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 296

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобиля Nissan Almera с 2013 года выпуска.

- Автор: —

- Издательство: За рулем

- Год издания: —

- Страниц: 255

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей Nissan Almera и Nissan Sunny с 2000 года выпуска с бензиновыми двигателями объемом 1,5/1,8 л.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 376

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan Almera Classic серии B10 с 2006 года выпуска.

- Автор: —

- Издательство: Автонавигатор

- Год издания: 2007

- Страниц: 344

- Формат: DjVu

- Размер: 28,7 Mb

Инструкция на русском языке для Nissan Almera N15 1995, содержит справочные данные и описание основных моментов эксплуатации автомобиля.

Рекомендуем перед началом использования изучить руководство, это позволит избежать проблем при эксплуатации и узнать о всех функциях и особенностях автомобиля.

Информация о файле: 90.12 Мб

manual-nissan-almera-n15-1995

◀Скачать руководство для Nissan Pathfinder 2010

Скачать руководство для Nissan Almera 2013▶

This manual contains maintenance and repair procedures for NISSAN model N15 series. In order to assure your safety and the efficient functioning of the vehicle, this manual should be read thoroughly. It is especially important that the PRECAUTIONS in the Gl section be completely understood before starting any repair task. All information in this manual is based on the latest product information at the time of publication. The right is reserved to make changes in specifications and methods at any time without notice.

The proper performance of service is essential for both the safety of the technician and the efficient functioning of the vehicle. The service methods in this Service Manual are described in such a manner that the service may be performed safely and accurately. Service varies with the procedures used, the skills of the technician and the tools and parts available. Accordingly, anyone using service procedures, tools or parts which are not specifically recommended by NISSAN must first be completely satisfied that neither personal safety nor the vehicle’s safety will be jeopardized by the service method selected.

CONTENTS

- GENERAL INFORMATION

- MAINTENANCE

- ENGINE MECHANICAL

- ENGINE LUBRICATION & COOLING SYSTEMS

- ENGINE CONTROL SYSTEM

- ACCELERATOR CONTROL, FUEL & EXHAUST SYSTEMS

- CLUTCH

- MANUAL TRANSAXLE

- AUTOMATIC TRANSAXLE

- FRONT AXLE & FRONT SUSPENSION

- REAR AXLE & REAR SUSPENSION

- BRAKE SYSTEM

- STEERING SYSTEM

- RESTRAINT SYSTEM

- BODY & TRIM

- HEATER & AIR CONDITIONER

- ELECTRICAL SYSTEM

- ALPHABETICAL INDEX

Language: English

Format: PDF

Pages: 1712

Nissan Almera N15 series Service Manual

- Главная

- Nissan

- Almera

- Книга по эксплуатации и ремонту Nissan Almera N15 1995-1999 гг.

Год выпуска:

1995 — 1999 гг.

Найдено 5 книг стоимостью от 444 руб.

Быстро купить книгу в оригинальной качественной версии PDF от издательства

Купить бумажную версию книги с доставкой по вашему адресу

Скачать руководство с предоставленного файлообменника

Команда нашего сайта предоставляет вам возможность скачать руководство по ремонту, диагностике и техническому обслуживанию автомобилей Nissan Almera N15, которые выпускались с 1995 по 1999 года.

Мануал содержит в себе всю информацию по автомобилям Nissan Almera N15 с бензиновыми и двигательными двигателями. Бензиновые двигатели представлены в следующих вариациях объёма: 1.6, 2.0 и малолитражный мотор – 1.4 литра. Дизельные двигатели автомобилей Nissan Almera N15 представлены лишь одним мотором, объёмом 2.0 литра.

Пособие включило в свой состав не только голый текст, но и набор иллюстраций, которые присутствуют в каждом разделе руководства. Каждой детали автомобиля отведена отдельная глава. В этой главе, вы найдете правила и порядок проведения диагностики и ремонта детали в случае поломки, для этого в пособии и присутствуют иллюстрации, которые графически объясняют, как правильно диагностировать и ремонтировать деталь.

Эксплуатация Nissan Almera

Похожие руководства на сайте

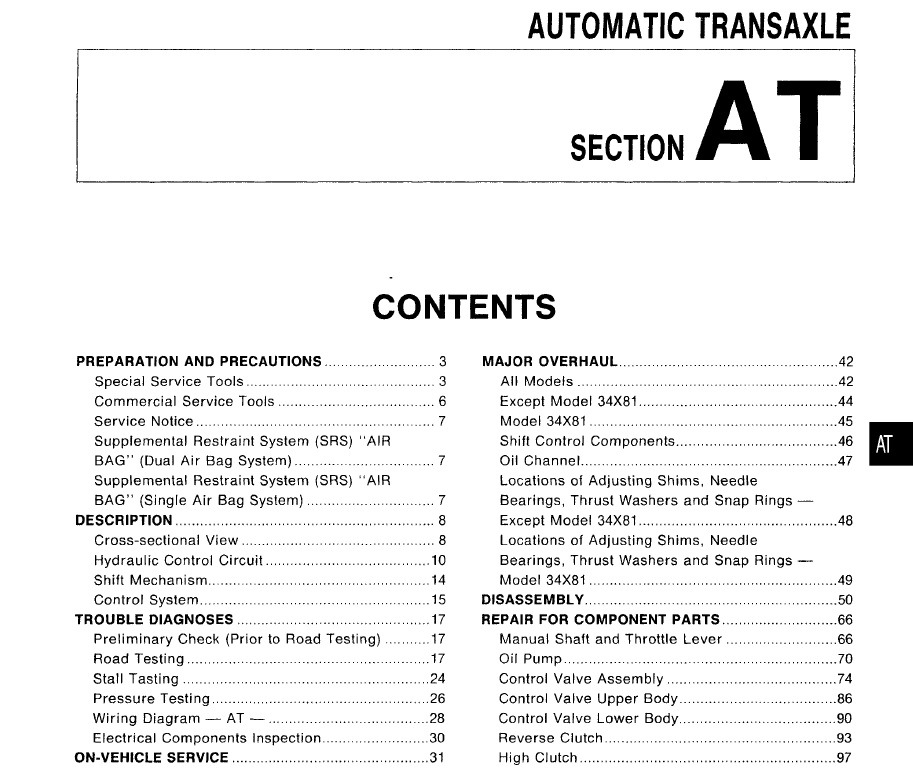

AUTOMATIC TRANSAXLE

AT

SECTION

CONTENTS

PREPARATION AND PRECAUTIONS

Special

Service

Commercial

Service

Tools

Service

Notice

Restraint

System

Supplemental

Restraint

BAG»

Air Bag System)

(Single

All Models

Except

Model

Model

34X81

System

(SRS) «AIR

Cross-sectional

View

Control

Circuit

42

42

34X81

.44

45

Shift Control

7

DESCRIPTION

Hydraulic

3

(SRS) «AIR

(Dual Air Bag System)

MAJOR OVERHAUL..

6

7

Supplemental

BAG»

Tools

3

Components

46

Oil Channel

47

Locations

of Adjusting

7

Bearings,

Thrust

8

Except

8

Locations

of Adjusting

10

Bearings,

Thrust

Model

Shims,

Washers

Needle

and Snap Rings —

34X81

.48

Shims,

Washers

Needle

and Snap Rings —

Shift Mechanism

14

Control

15

DiSASSEMBLy

17

REPAIR FOR COMPONENT PARTS

System

TROUBLE DIAGNOSES

Preliminary

(Prior

to Road Testing)

34X81

.49

50

66

17

Manual

Road Testing

17

Oil Pump

Stall Tasting

24

Control

Valve

Assembly

74

Pressure

26

Control

Valve

Upper

Body

86

28

Control

Valve

Lower

Body

30

Reverse

31

High Clutch

31

Forward

33

Low & Reverse

35

Rear Internal

36

Overrun

37

Output

Wiring

Check

Model

Testing

Diagram

Electrical

—

AT —

Components

Inspection

ON-VEHICLE SERVICE

Control

Valve

Assembly

Throttle

Wire Adjustment..

Control

Cable

Governor

Inhibitor

Differential

and Accumulator

Installation

and Adjustment

Valve

Switch

Adjustment

Side Oil Seal Replacement..

REMOVAL AND INSTALLATION

Removal

Installation

Shaft and Throttle

Lever

66

70

90

Clutch

93

97

Clutch

and Overrun

108

Forward

Clutch

112

Gear,

Idler

Gear,

Reduction

Pinion

Gear and Bearing

39

—

Model

34X81

39

Output

.40

Shaft,

Idler Gear,

Gear and Bearing

Band Servo

Hub and

Hub

Output

37

Except

102

Brake

Gear,

Clutch

Shaft,

Clutch

Piston

Retainer

116

Reduction

Retainer

—

Model

Assembly

Final Drive —

Except

Model

Final Drive —

Model

34X81

Pinion

34X81

121

126

34X81

131

135

•

i

CONTENTS

ASSEMBLy

Assembly 1

Adjustment 1

Assembly 2

Adjustment 2

Assembly 3

138

138

139

147

151

(Cont’d.)

Adjustment 3

Assembly 4

SERVICE DATA AND SPECIFICATIONS (SOS)

General Specifications

Specifications and Adjustments

155

When you read wiring diagrams:

• Read GI section, «HOW TO READ WIRING DIAGRAMS» .

• See EL section, «POWER SUPPLY ROUTING» for power distribution circuit.

157

158

165

165

165

PREPARATION AND PRECAUTIONS

Special Service Tools

Tool number

Tool name

Description

8T25058001

Oil pressure gauge set

G) 8T25051001

Oil pressure gauge

@ 8T25052000

Hose

@ 8T25053000

Joint pipe

@ 8T25054000

Adapter

@ 8T25055000

Adapter

Measuring line pressure and governor

pressure

NT097

KV31103000

Drift

Installing differential side oil seal

(Use with 8T35325000)

a: 59 mm (2.32 in) dia.

b: 49 mm (1.93 in) dia.

NT105

8T35325000

Drift

Installing differential side oil seal

(Use with KV31103000)

a: 215 mm (8.46 in)

b: 25 mm (0.98 in) dia.

c: M12 x 1.5P

NT417

Removing and installing clutch return

spring

KV31103200

Clutch spring compressor

a: 179 mm (7.05 in)

b: 76 mm (2.99 in) dia.

c: 174 mm (6.85 in)

NT425

Removing and installing parking rod plate

and manual plate

8T23540000

Pin punch

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

NT442

Installing throttle lever and manual shaft

retaining pins

Removing and installing differential pinion

mate shaft lock pin.

KV32101000

Pin punch

a: 4 mm (0.16 in) dia.

NT410

AT-3

•

PREPARATION AND PRECAUTIONS

Special Service Tools (Cont’d)

Tool number

Tool name

Description

ST3306S001

Removing differential side bearing inner

Differential side bearing

puller set

race

CD

ST33051001

Puller

@ ST33061000

Adapter

,~

a

NT413

KV381054S0

(ST33290001)

Puller

a:

b:

c:

d:

e:

38 mm (1.50 in) dia.

28.5 mm (1.122 in) dia.

130 mm (5.12 in)

135 mm (5.31 in)

100 mm (3.94 In)

• Removing differential side oil seal

• Removing idler gear bearing outer race

— EXCEPT MODEL 34X81 • Removing output shaft bearing outer

race from bearing retainer

• Removing output gear bearing outer

race from bearing retainer

— MODEL 34X81 • Removing differential side bearing outer

race

• Removing needle bearing from bearing

retainer

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

NT414

ST27180001

Puller

• Removing idler gear

• Removing output gear (Except model

34X81)

a: 100 mm (3.94 In)

b: 110 mm (4.33 in)

c: M8 x 1.25P

NT424

ST30031000

Puller

Removing reduction pinion gear bearing

inner race (Except model 34X81)

a: 90 mm (3.54 In) dia.

b: 50 mm (1.97 in) dia.

NT411

ST30021000

Puller

Removing differential side bearing

(Except model 34X81)

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

NT411

ST35272000

Drift

• Installing reduction pinion gear bearing

inner race

• Installing idler gear bearing inner race

• Installing output gear bearing inner race

(Except model 34X81)

~

a: 72 mm (2.83 in) dia.

b: 35.5 mm (1.398 in) dia.

NT426

AT-4

PREPARATION AND PRECAUTIONS

Special Service Tools (Cont’d)

Tool number

Tool name

Description

8T37830000

Drift

Installing idler gear bearing outer race

a: 62 mm (2.44 in) dia.

b: 39 mm (1.54 in) dia.

NT427

8T33200000

Drift

Installing differential side bearing (Except

model 34X81)

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

NT091

8T35271000

Drift

• Installing idler gear

• Installing output gear (Except model

34X81)

a: 72 mm (2.83 in) dia.

b: 44 mm (1.73 in) dia.

NT115

8T33400001

Drift

• Installing oil pump housing oil seal

• Installing output gear bearing outer race

onto bearing retainer (Except model

34X81)

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

NT086

KV40104840

Drift

Installing output shaft bearing outer race

onto bearing retainer (Except model

34X81)

a: 49 mm (1.93 in) dia.

NT108

b: 42 mm (1.65 in) dia.

— MODEL 34X81 • Measuring turning torque of final drive

KV38105710

Preload adapter

assembly

• Measuring clearance between side gear

and differential case with washer

• Selecting differential side bearing

adjusting shim

NT087

8T35321000

Drift

Installing output shaft bearing

(Model 34X81)

a: 49 mm (1.93 in) dia.

b: 41 mm (1.61 in) dia.

NT073

ST30633000

Drift

Installing differential side bearing outer

race (Model 34X81)

a: 67 mm (2.64 in) dia.

b: 49 mm (1.93 in) dia.

NT073

AT-5

•

PREPARATION AND PRECAUTIONS

Commercial Service Tools

Tool name

Description

Puller

=m

o

NT077

0

Drift

• Removing idler gear bearing inner race

• Removing and installing band servo piston snap ring

— EXCEPT MODEL 34X81 • Removing output gear bearing inner

race

• Removing differential side bearing

Removing idler gear bearing inner race

(Except model 34X81)

NT109

~

a: 34 mm (1.34 in) dia.

Installing needle bearing onto bearing

retainer (Model 34X81)

Drift

NT109

~

a: 36 mm (1.42 in) dia.

Removing output gear bearing inner race

(Except model 34X81)

Drift

NT109

~

a: 33 mm (1.30 in) dia.

Removing differential side bearing (Except

model 34X81)

Drift

NT109

~

a: 38 mm (1.50 in) dia.

Removing output shaft bearing inner race

(Except model 34X81)

Drift

NT110

a: 70 mm (2.76 in) dia.

b: 30 mm (1.18 in) dia.

~

Installing output shaft bearing inner race

(Except model 34X81)

Drift

a:

b:

c:

d:

~d

NT111

AT-6

70 mm (2.76 in) dia.

34 mm (1.34 in) dia.

30 mm (1.18 in) dia.

2 mm (0.08 in)

PREPARATION AND PRECAUTIONS

Service Notice

•

•

•

•

•

•

•

Before proceeding

with disassembly,

thoroughly clean the outside of the transaxle. It is

important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

Disassembly should be done in a clean work

area.

Use lint-free cloth or towels for wiping parts

clean. Common shop rags can leave fibers

that could interfere with the operation of the

transaxle.

Place disassembled parts in order, on a parts

rack, for easier and proper assembly.

All parts should be carefully cleaned- with a

general

purpose,

non-flammable

solvent

before inspection or reassembly.

Gaskets,

seals

and O-rings

should

be

replaced any time the transaxle is disassembled.

It is very important to perform functional tests

whenever they are indicated.

•

•

•

•

•

The valve body contains precision parts and

requires

extreme

care when

parts are

removed and serviced. Place disassembled

valve body parts in order, on a parts rack, for

easier and proper assembly. Care will also

prevent springs and small parts from becoming scattered or lost.

Properly installed vales, sleeves, plugs, etc.

will slide along their bores in the valve body

under their own weight.

Before assembly,

apply a coat of recommended ATF to all parts. Apply petroleum

jelly to protect O-ring and seals, or hold bearings and washers in place during assembly.

Do not use grease.

Extremely care should be taken to avoid damage to O-rings, seals and gaskets when

assembling.

After overhaul, refill the transaxle with new

ATF.

Supplemental Restraint System (SRS) «AIR

BAG» (Dual Air Bag System)

The Supplemental Restraint System «Air Bag» used along with a seat belt, helps to reduce the risk or

severity of injury to the driver and front passenger in a frontal collision. The Supplemental Restraint

System consists of air bag modules (located in the center of the steering wheel and on the instrument

panel on the passenger side), a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

•

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

•

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system.

Ii

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the

harness connectors or for the complete harness, for easy identification.

Supplemental Restraint System (SRS) «AIR

BAG» (Single Air Bag System)

The Supplemental Restraint System «Air Bag» and used along with a seat belt, helps to reduce the risk

or severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of

an air bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable. Information necessary to service the system safely is included in the

RS section of this Service Manual.

WARNING:

•

To avoid rendering the SRS inoperative, which could increase the

in the event of a collision which would result in air bag inflation, all

by an authorized NISSAN dealer.

•

Improper maintenance, including incorrect removal and installation

injury caused by unintentional activation of the system.

•

Do not use electrical test equipment on any circuit related to the

Service Manual.

AT-7

risk of personal injury or death

maintenance must be performed

of the SRS, can lead to personal

SRS unless instructed

to in this

•

DESCRIPTION

Cross-sectional View

EXCEPT MODEL 34X81

Band servo piston

Reverse clutch drum

Converter housing

High clutch

Brake band

Torque converter

SAT502HB

AT-8

DESCRIPTION

Cross-sectional View (Cant’ d)

MODEL 34X81

Reverse clutch drum

Band servo piston

High clutch

Front planetary gear

Reverse clutch

Low one-way clutch

Oil pump assembly

Brake band

Rear planetary gear

Converter housing

Forward clutch

Overrun clutch

Low & reverse brake

Torque converter

Input shaft

c

Idler gear

…

-;-

I

,»‘I

L_

Forward one-way clutch

Reduction pinion gear

Final gear

Differential case

SAT101EA

AT-9

•

DESCRIPTION

Hydraulic Control Circuit

MODEL 34X68

Low & reverse

brake

High clutch

Forward

clutch

4th

speed cut

valve

Overrun

clutch

control

valve

Lock-up

control

valve

1-2

shift

valve

Torque

‘~ ..•.•

converter

relief

..••…..

valve

..

>..•.••••

Governor

valve

X

: Drain port

Detent valve

: Orifice

SAT1961

AT-10

DESCRIPTION

Hydraulic Control Circuit (Cont’d)

MODEL 34X69 AND 34X70

Torque

converter

High clutch

Forward

clutch

Oil

pump

4th

speed

cut

valve

i

accumulator

valve

Lock-up

control

valve

Overrun

clutch

control

valve

II

•

1-2

shift valve

00 cancel

solenoid

X

: Drain

=:= :

port

Orifice

SAT509H

AT-11

DESCRIPTION

Hydraulic Control Circuit (Cont’d)

MODEL 34X80

Low & reverse

Torque

converter

Oil

brake

Overrun

,clutch

tJ

I g~

pump

I

~J

speed cut

valve

C-1

(~

Forward

clutch

—;::;-;r.]O

~~ l]

~

J~

~

UL «-‘ IU4~1~~

~%~

1

~frEJ!

-!

6 ~,

Lock-up_

control

valve

tf1

(T,

N

~iJ —

Reverse

clutch

Band servo

(Jp::-

1 ~

4th

Overrun

clutch

controlvalve

High clutch

-~

1-2

accumulator

valve

cooler-

L-

_

—

m

0

~,—J

—

,-O…J

ILJ

ar

r

I ‘—,~

r::r=<

,’-

=-

II

.

,,’

~tL

‘

(

I

‘

IJ

—

—

(

I

,

~1

i i

xU

~H

::l.

-= ~ I

rr=-

LL:

L~

Torque x'»

converter

relief

valve

~

x

—

r

~

i i

‘

2 ~ ‘-

3-4 shift valv~-HiliJI

Governor../l

valve

Pressure

regulator

valve

~M~ ·

F= f=’l

.,.11

L 2-3

~

=—=-.J

!lJF

—

II

:;;; ~ I

=-.—‘

00 cancel

solenoid

»

1-

~

L…—…l

I

nn

I

1-2

shift

valve

~reducing_

~

«~’L—.J

lJl.

U

p RNb’21

11

r’

.

4-2

I ~valve=

~

seq!!.enc~

,-=-valve—j

h

1J;;;.Q»t….

Ma~alve

II

~

II

‘i-VD

-,

.»

c: I

I

modifier

Throttle

valve

II

•

‘:fj’~1

I

:=~-‘

Pressure

modifier valve

: Drain port

~I»

shift

valve

..-

D ~Y&

X

I~

J~

Detent valve

1″

Throttle valve

.

If.’

.

«;’Jnn!

~

~

l…

,

Klckdown

modifier

valve

:::::: : Orifice

SAT1971

AT-12

DESCRIPTION

Hydraulic Control Circuit (Cont’d)

MODEL 34X81

Oil

pump

Torque

converter

High clutch

4th speed

cut valve

Lock-up

control valve

Overrun

clutch

control valve

•

1-2

shift valve

3-4 shift valve

X

Drain port

:::::= : Orifice

SAT1981

AT-13

DESCRIPTION

Shift Mechanism

CONSTRUCTION

,:-1

18

SAT214H

ill

@

@

@

@

Brake band

Reverse clutch

High clutch

@

Front sun gear

Front pinion gear

@

o

@

@l

@

@

Torque converter

Oil pump

Input shaft

FUNCTION

@

@

@

@

Front internal gear

Front planetary carrier

Rear sun gear

Rear pinion gear

Rear internal gear

Rear planetary carrier

Forward clutch

Forward one-way clutch

@

@

@

@

@

@

@

@

Overrun clutch

Low one-way clutch

Low & reverse brake

Parking pawl

Parking gear

Output shaft

Idle gear

Output gear

OF CLUTCH AND BRAKE

Glutch and brake components

Abbr.

Function

Reverse clutch

RIG

To transmit input power to front sun gear

High clutch

HIG

To transmit input power to front planetary carrier

Forward clutch

FIG

To connect front planetary carrier with forward one-way clutch

Overrun clutch

OIG

To connect front planetary carrier with rear internal gear

Brake band

BIB

To lock front sun gear

Forward one-way clutch

F/O.G

Low one-way clutch

LlO.G

Low & reverse brake

L & RIB

When forward clutch is engaged, to stop rear internai gear from rotating in opposite direction against engine speed

To stop front planetary carrier from rotating in opposite direction

against engine speed

To lock front planetary carrier

AT-14

DESCRIPTION

Shift Mechanism (Cont’d)

OPERATION

OF CLUTCH AND BRAKE

Band servo

Shift posi- Reverse

tion

clutch

High

clutch

Forward

clutch

Overrun

clutch

2nd

apply

3rd

release

Forward

Low

one-way one-way

clutch

clutch

4th

apply

Low &

reverse

brake

Lock-up

PARK POSITION

P

R

REVERSEPOSITION

0

0

NEUTRAL POSITION

N

D

‘4

1st

0

’10

2nd

0

’10

0

’10

‘2@

@

‘3@

@

3rd

0

0

4th

0

@

1st

0

0

2nd

0

0

1st

0

0

2nd

0

0

• •

••

• •

•• •

•

0

2

0

1

‘1

‘2

‘3

‘4

o

Remarks

0

Automatic shift

1<—>2<—>3<—>4

0

Automatic shift

1<—>2

0

Locks (held stationary) in 1st

speed 1 <— 2

Operates when overdrive switch is sel to «OFF».

Oil pressure is applied to both 2nd «apply» side and 3rd «release» side of band servo piston. However, brake band does not contract

because oil pressure area on the «release» side is greater than that on the «apply» side.

Oil pressure is applied to 4th «apply» side in condition ‘2 above, and brake band contracts.

AIT will not shift to 4th when overdrive switch is set to «OFF» position.

Operates.

•

Operates. During «progressive»

@

Operates but does not affect power transmission.

acceleration.

Control System

CONTROL SYSTEM

Engine

AIT

:

Governor valve

1

1

I

1

Lock-up cancel

solenoid’1

‘1:

1

1

Equipped on model

34X69, 34X70 and 34X80

I

: Electrical signal

1

1

Overdrive

control switch

OD cancel solenoid :

;

….

: Hydraulic pressure

I

J

L

AT-15

SAT985HA

•

DESCRIPTION

NOTE

AT-16

TROUBLE DIAGNOSES

Preliminary Check (Prior to Road Testing)

Fluid leakage

AIT FLUID CHECK

Fluid leakage check

1.

2.

3.

4.

Clean area suspected of leaking, — for example, mating

surface of converter housing and transmission case.

Start engine, apply foot brake, place selector lever in «0»

position and wait a few minutes.

Stop engine.

Check for fresh leakage.

SAT288G

Fluid condition check

Fluid color

Suspected problem

Oark or black with burned odor

Wear of frictional material

Milky pink

Water contamination

— Road water entering through

filler tube or breather

Varnished fluid, light to dark brown

and tacky

Oxidation

— Over or under filling

— Overheating

Fluid level check — Refer to MA section (CHASSIS AND

BODY MAINTENANCE).

Road Testing

Perform

AT-20.

road

tests

using

«Symptom»

chart.

Refer to page

«P» POSITION

1.

2.

Place selector lever in «P» position and start engine. Stop

engine and repeat the procedure in all positions, including

neutral position.

Stop vehicle on a slight upgrade and place selector lever in

«P» position. Release parking brake to make sure vehicle

remains locked.

«R» POSITION

1.

2.

Manually move selector lever from «P» to «R», and note

shift quality.

Drive vehicle in reverse long enough to detect slippage or

other abnormalities.

«N» POSITION

1.

2.

Manually move selector lever from «R» and «0» to «N» and

note shift quality.

Release parking brake with selector lever in «N» position.

Lightly depress accelerator

pedal to make sure vehicle

does not move. (When vehicle is new or soon after clutches

have been replaced, vehicle may move slightly. This is not

a problem.)

AT-17

•

TROUBLE DIAGNOSES

Road Testing (Cont’d)

«0» POSITION

SAT612GA

1. Manually move selector lever from «N» to «D» position, and

note shift quality.

2. Using the shift schedule as a reference, drive vehicle in «D»

position. Record, on symptom chart, respective vehicle

speeds at which up-shifting and down-shifting occur. These

speeds are to be read at three different throttle positions

(light, half and full), respectively. Also determine the timing

at which shocks are encountered during shifting and which

clutches are engaged.

3. Determine whether lock-up properly occurs while driving

vehicle in proper gear position and at proper vehicle speed.

4. Check to determine if shifting to overdrive gear cannot be

made while OD control switch is «OFF».

5. Drive vehicle in «D3» position at half to light throttle position. Keep driving at 60 to 70 km/h (34 to 43 MPH). FUlly

depress accelerator pedal to make sure transaxle downshifts from 3rd to 2nd gear.

6. Drive vehicle in «D2» position at half to light throttle position. Keep driving at 25 to 35 km/h (16 to 22 MPH). Fully

depress accelerator pedal to make sure transaxle downshifts from 2nd to 1st gear.

SAT497G

«2» POSITION

1. Shift to «2» position and make sure vehicle starts in 1st

gear.

2. Increase vehicle speed to make sure transaxle upshifts from

1st to 2nd gear.

3. Further increase vehicle speed. Make sure transaxle does

not upshift to 3rd gear.

4. Drive vehicle in «22» position at half to light throttle position.

Keep driving at 25 to 35 km/h (16 to 22 MPH). Fully depress

accelerator pedal to make sure transaxle downshifts from

2nd to 1st gear.

5. Allow vehicle to run idle while in «2» position to make sure

that transaxle downshifts to 1st gear.

6. Move selector lever to «D» position and allow vehicle to

operate at 30 to 40 km/h (19 to 25 MPH). Then, shift to «2»

position to make sure transaxle downshifts to 2nd gear.

«1» POSITION

1. Place selector lever in «1» position and accelerate vehicle.

Make sure transaxle does not shift from 1st to 2nd gear

although vehicle speed increases.

2. Drive vehicle in «1» position. Release accelerator pedal to

make sure that engine compression acts as a brake.

3. Place selector lever in «D» or «2» position and allow vehicle to run at 15 to 25 km/h (9 to 16 MPH). Then move selector lever to «1» position to make sure transaxle downshifts

to 1st gear.

AT-18

TROUBLE DIAGNOSES

Road Testing (Cont’d)

SHIFT SCHEDULE

Drive the vehicle for approx. 10 minutes. Measure the oil temperature. When the oil temperature

becomes between 50 and

80°C (122 and 176°F), carry out this check.

VEHICLE SPEED WHEN SHIFTING

GEARS

Model 34X68

Throttle position

Full throttle

Half throttle

Vehicle speed km/h (MPH)

0, ~ O2

O2

->

03

48 — 56

88 — 96

(30 — 35)

(55 — 60)

03

->

04

04

—

~

03

03

->

O2

O2

->

0,

12

~

1,

133 — 141

80 — 88

37 — 45

45 — 53

(83 — 88)

(50 — 55)

(23 — 28)

(28 — 33)

31 — 39

54 — 62

102 — 110

75 — 83

44 — 52

7 — 15

45 — 53

(19 — 24)

(34 — 39)

(63 — 68)

(47 — 52)

(27 — 32)

(4 — 9)

(28 — 33)

O2

03

Model 34X69 and 34X70

Throttle pasition

Full throttle

Half throttle

Vehicle speed km/h (MPH)

0, ~ O2

~

03

51 — 60

94 — 102

(32 — 37)

(58 — 63)

->

04

04

—

~

03

03

->

O2

O2

~

0,

12

~

1,

136 — 144

85 — 93

40 — 48

48 — 56

(85 — 89)

(53 — 58)

(25 — 30)

(30 — 35)

30 — 38

52 — 60

97 — 105

67 — 75

42 — 50

8 — 16

48 — 56

(19 — 24)

(32 — 37)

(60 — 65)

(42 — 47)

(26 — 31)

(5 — 10)

(30 — 35)

0, ~ O2

O2

03

Model 34X80

Throttle position

Full throttle

Half throttle

Vehicle speed km/h (MPH)

->

03

52 — 60

100 — 108

(32 — 37)

(62 — 67)

~

04

04

—

->

03

03

~

O2

O2

->

0,

1″ -> 1,

145 — 153

90 — 98

40 — 48

49 — 57

(90 — 95)

(56 — 61)

(25 — 30)

(30 — 35)

30 — 38

53 — 61

103 — 111

69 — 77

42 — 50

8 — 16

49 — 57

(19 — 24)

(33 — 38)

(64 — 69)

(43 — 48)

(26 — 31)

(5 — 10)

(30 — 35)

Model 34X81

Throttle position

Full throttle

Half throttle

Vehicle speed km/h (MPH)

0, ~ O2

O2

->

03

58 — 66

107 — 115

(36 — 41)

(66 — 71)

03

~

04

04

—

->

03

03

->

O2

O2

~

0,

12

~

1,

160 — 168

96 — 104

39 — 47

48 — 56

(99 — 104)

(60 — 65)

(24 — 29)

(30 — 35)

33 — 41

57 — 65

105 — 113

69 — 77

45 — 53

8 — 16

48 — 56

(21 — 25)

(35 — 40)

(65 — 70)

(43 — 48)

(28 — 33)

(5 — 10)

(30 — 35)

AT-19

•

TROUBLE DIAGNOSES

Road Testing (Cont’d)

ROAD TEST SYMPTOM CHART

Numbers are arranged in order of probability.

Perform inspections starting with number one

and work up.

Circled numbers indicate that the transaxle

must be removed from the vehicle.

ON VEHICLE

~

Q)

c:

.;:

~

‘;:

::l

0″

«lJ

Iii

~

«lJ

c:

ro

;:

(/)

(/)

~

;:

Ol

c:

~

~

::l

(/)

(/)

Q)

>

Iii

>

ec s:0

E

0

c:

0

.E

I-

c:

W

ec

:::i

0

2

5

3

4

7

When shifting from 1st to 2nd or

2nd to 3rd

2

4

3

6

When shifting from 3rd to 4th

2

4

3

5

When shifting from D to 2 and 1

position.

When OD switch is set from

«ON» to «OFF»

2

4

3

5

When shifting from 2nd to 1st in

«1» position

2

4

3

5

When shifting from 1st to 2nd

2

4

3

5

When shifting from 2nd to 3rd

2

4

3

6

When shifting from 3rd to 4th

2

4

3

5

Sharp shocks in shifting from «N» to «D» position

Shift slippage with accelerator

pedal depressed

:0

ro

.l:l

od

<.l

0

~

Q)

~e

Q)

c:

‘0,

~

0Q)

0

When shifting from 4th to 2nd

2

5

3

6

When shifting from 4th to 3rd

2

4

3

6

When shifting from 4th to 1st

and shifting from 3rd to 1st

2

5

3

6

When vehicle starts

2

4

3

6

When upshifting

2

4

3

7

When shifting from «D» to «2»

and» 1″ position

2

4

3

5

When OD switch is set from

«ON» to «OFF»

2

4

3

7

When shifting from 2nd to 1st in

«1» position

2

4

3

5

Too Iowa gear change point

from 2nd to 3rd and from 3rd to

2nd.

3

2

6

Too high a gear change point

from 2nd to 3rd and from 3rd to

2nd.

3

2

6

Too Iowa gear change point

from 2nd to 1st in «1» position.

3

2

6

Too high a gear change point

from 2nd to 1st in «1» position.

3

2

6

Poor power/acceleration

No engine braking

Shift quality

AT-20

Q)

>

Iii

>

Q)

E

~e

l-

Q)

>

co>

Q)

~

eC

>

Iii

>

ro

«3

~

<.l

~

B

«lJ

0-

>

2

Q)

Shift slippage when upshifting

Q)

>

Iii

>

Q)

Q)

Q)

ro

>

Iii

>

Q)

C

2

«lJ

c:

‘0

Q)

>

Iii

>

Ol

: Valve expected to be malfunctioning

Shift shocks

~

Ol

~

~

::l

(/)

(/)

~

0

Q)

>

Iii

>

Q)

Q)

>

Iii

>

>

Iii

>

~

.c

;:

;;:

(/)

(/)

M

C)’

N

.l:l

.2

u

c:

eQ;

>

0

«lJ

0

E

~

::l

(/)

(/)

Q)

0:

TROUBLE DIAGNOSES

Road Testing (Cont’d)

…

..

ON VEHICLE

…

~

OFF VEHICLE

Q)

>

Iii

>

~

~0

~0

Q)

>

Iii

Q)

>

Q)

>

Iii

Qi

Q)

>

>

~

Iii

Q)

>

Q)

;;::

(;

‘6

c;;

0

~

~

E

E

c:::

~

0

(J

(J

«0

nl

-‘»

(J

‘}’

~

~

>

Q)

>

Iii

Iii

>

>

OJ

OJ

U

c:::

«E

:;:;

‘}’

C»)

c:::

~

«0

~

ii)

~

>

Iii

0

>

~

CT

(;

l-

Q)

>

Oi

Q)

Q)

Q)

~

«0

>

:;

>

Iii

>

0

1:

E

«0

u

Q)

Q)

~

.r:

I-

Q)

0-

‘»

.r:

::

Q)

u

c:::

0

~

~

0

..J

~

Q)

0(J

>

Oi

«2

u

Q)

.r:

>

.B

CT

Q)

‘»

N

.}

«0

0

~

~

‘»‘»

Ci

Q)

~

0

c:::

(j;

>

0

~

c:::

Q)

>

Oi

>

(;

c:::

(j;

>

0

~

‘»

>

Iii

Q)

~

~

~>

c:::

u

B

c:::

Q)

(5

‘»

Qj

(J

c:::

nl

(J

D

0

~

U

~

Q)

t

Q)

>

c:::

0

u

~

Q)

CT

0

E

~

Q)

‘»

nl

Q)

~

0

~

Q)

«~

~

«0

.r:

u

nl

U

.r:

.r:

>-

.B

~

~

U

‘»

c:::

nl

‘»(;

Z

.r:

(;

.B

~~

E

~

~~

E

~

(;

(J

(J

I-

<{

(J

(J

<{

c:::

ill

«0

D

OJ

«;:

«~

‘»c:::0

E

c:::

E’

:;

c:::

.B

«~

«2′»

1:

0

(J

D

0

(j;

t

>

c:::

0

u

~

Q)

CT

(;

l-

5

.r:

u

.B

Q)

6

I

.r:

~

0-

E

~

0-

u

Q)

~

Q)

>

Q)

(5

e::

9

8

.r:

.B

~

u

.r:

OJ

I

:;

u

nl

Q)

c:::

«0

0

«0

tii

tii

(;

(;

~

LL

~

LL

.B

~

U

c:::

;:

(j;

>

0

>nl

~

Q)

c:::

Q)

>

~

o1S

~

0

~

0

..J

A

8

5

4

7

5

5

5

If

I[

5

4

5

4

5

4

5

AT-21

c:::

lD

0..

~

6

6

6

8

7

7

6

10

11

7

8

11

8

9

7

13

14

15

10

16

17

12

11

9

9

10

8

8

8

6

4

OJ

~

8

9

0

-‘»

Q)

7

6

6

u

.Q

9

9

6

E

nl

c:::

6

7

7

«0

7

7

4

0

0-

tii

7

8

5

c:::

Q)

c:::

Q)

~

0

..J

tl

:;

U

8

8

•

.r:

.r:

u

7

•

TROUBLE DIAGNOSES

Road Testing (Cont’d)

~

Numbers are arranged in order of probability.

Perform inspections starting with number one

and work up.

Circled numbers indicate that the transaxle

must be removed from the vehicle.

(J)

. Valve expected to be malfunctioning

~

«0

::J

c:

III

‘0

c:

III

a;

Lock-up quality

(J)

:0

III

<.>

£

.~

rtl

~

eC

.8

:0

6

u

EO

0

J::.

Q)

rtl

~

.~

(J)

E

e

J::.

~

01

c:

~

(J)

.!::

01

c:

UJ

oil

~

::J

rtl

rtl

~

0.

(J)

c:

(J)

>

0;

>

ec

0

::i

u

Failure to change gear from 4th

to 2nd with accelerator pedal

depressed.

3

2

6

Failure to change gear from 3rd

to 2nd with accelerator pedal

depressed.

3

2

6

Failure to change gear from 1st

to 2nd in «0» and «2» position.

3

2

6

Vehicle does not start from

«1st» in «0» and «2» position.

3

2

6

Failure to change gear to 3rd

and 4th in «0» position.

3

2

6

Changes gear to 1st directly

when selector lever is set from

«D» to «1» position.

3

2

6

Changes gear to 2nd in «1»

position.

3

2

6

Lock-up point is extremely high

or low.

3

2

6

Torque converter does not lockup.

3

2

7

Lock-up is not released when

accelerator pedal is released.

Engine does not start in «P» and «N» positions or engine starts

in positions other than «P» and «N» positions.

2

2

Vehicle moves with selector lever in «P» position.

AT-22

3

.8III

«0

0.

J::.

~

>

>

0;

>

(J)

«0

(J)

(J)

(J)

>

0;

>

(J)

E

0

.c~

>

0;

>

(J)

c

.~

rr

«0

(J)

>

0;

>

01

c:

.;::

0;

Shift quality

..

ON VEHICLE

(J)

:;

01

>

0;

>

0;

~

~

::J

::J

rtl

rtl

(J)

c:

III

::E

a:

>

0;

>

J::.

ii

0

<.>

(J)

(J)

(J)

>

0;

>

>

0;

>

>

0;

>

;:

‘E

;t:

J::.

rtl

J::.

rtl

«‘f

C’)

C’)

N

:c

rtl

C)’

(J)

eC

£

::J

(3

c:

~

0

E

~

2

::J

>

a:

li;

0

rtl

rtl

(J)

TROUBLE DIAGNOSES

Road Testing (Conl’d)

…

~ …

ON VEHICLE

~

OFF VEHICLE

QJ

>

OJ

>

…

«0

.0

c:

QJ

QJ

>

(5

OJ

>

OJ

QJ

…

OJ

>

>

QJ

>

0

.8

~

«0

E

c:

:;:

0

«0

-»

()

~

QJ

>

QJ

~

::l

E

::l

()

()

OJ

>

Ol

.~

E

:;:;

‘}’

C’)

>

OJ

>

Ol

c:

.0

::l

«0

~

u;

~

~

~

…

2

Qi

>

c:

0

()

QJ

::l

2»

0

f-

rr

0

(5

QJ

>

OJ

>

QJ

>

OJ

~

«0

0

E

QJ

E

2

.s::

f-

>

«5

()

«0

QJ

QJ

0.

en

.s::

::;

>

OJ

>

e1:

0

()

0.

l’

-»

()

0

..J

QJ

>

~

>

en

en

OJ

QJ

()

c:

QJ

::l

0QJ

en

N

..,;.

QJ

0.

0c:

Qi

>

QJ

>

OJ

>

ac:

Qi

>

0

0

Cl

Cl

4

5

4

5

4

5

4

5

4

5

4

5

4

5

4

5

4

5

…

en

>

.s::

.B

::l

t3

~

‘»

~

~en

0

2

>

«0

Qi

en

Z

.s::

>

c:

0

0

.~

«0

::l

E

QJ

>

OJ

QJ

en

.0

c:

~0

en

Qi

Q)

0

()

()

c:

‘»

()

Cl

0

QJ

::l

2″

0

f-

QJ

Cl

1ii

1ii

::l

::l

E

E

()

()

()

()

<{

<{

::l

::l

Ol

c:

..:;

.~

‘»

.s::

‘»

.B

en

c:

0

E

c:

~

7

.B

::l

t3

c:

c:

.B

.s::

«0

Qi

.~

t

.s::

.s::

en

>

c:

.B

::l

.B

::l

t3

e1:

0

()

Cl

0

QJ

0

()

QJ

::l

0-

0

f-

.s::

>-

0.

E

::l

0.

<5

u

QJ

en

Qi

>

QJ

a:

.s::

.B

::l

t3

.s::

Ol

I

«0

:a

~

0

u..

‘»d>

:;:

c:

0

«0

:a:;:

0

u..

.s::

.B

::l

t3

c:

.B

::l

t3

>-

‘»

:;:

d>

.s::

.B

.!!l

t3

QJ

~

QJ

>

~

t

>

:;:

:;:

0

..J

0

..J

QJ

0

0

QJ

c:

0

c:

c:

::l

o(l

0.

«0

c:

~ID

Start engine, apply foot brake, and place selector lever in

«0» position.

•

SAT7678

6. Accelerate to wide-open throttle gradually while applying

foot brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

• During test, never hold throttle wide-open for more than 5

seconds.

Stall revolution .standard:

Refer to SDS, AT-166.

SAT514G

8. Move selector lever to «N» position.

9. Cool off ATF.

• Run engine at idle for at least one minute.

10. Repeat steps 5 through 9 with selector lever in «2», «1» and

«R positions.

n

SAT7718

AT-24

TROUBLE DIAGNOSES

Stall Tasting (Cont’d)

JUDGEMENT

OF STALL TEST

Selector

Damaged

Judgement

lever position

o

L

L

H

o

o

L

o

H

L

D

H

2

H

R

o : Stall

H

L

revolution

: Stall revolution

than specified.

is normal.

is higher

: Stall revolution

than specified.

is lower

components

Forward

cluth

one-way

Engine

•

Torque converter

one-way clutch

Hydraulic

circuit

line pressure

clutch

Low one-way

clutch

for

control

(Line pressure

Reverse

is low.)

D

H

2

H

R

Selector

lever position

o

o

H

o

H

o

Clutches and brakes except

high clutch, brake band and

overrun clutch are OK.

(Condition of high clutch,

brake band and overrun

clutch cannot

stall test.)

be confirmed

by

Judgement

SAT871H

AT-25

TROUBLE DIAGNOSES

Pressure Testing

•

•

Test port for

line pressure

Location of pressure test port.

Always replace pressure plugs

bolts.

as they are self-sealing

governor pressure

SAT565D

LINE PRESSURE TEST PROCEDURE

1.

2.

Check AfT and engine fluid levels. If necessary, add fluid.

Drive vehicle for about 10 minutes until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 — 80°C (122 — 176°F)

3.

Install pressure

SAT647B

gauge to line pressure

port.

4. Set parking brake and block wheels.

Continue to depress brake pedal fully while

pressure test at stall speed.

performing

line

SAT513G

5.

Start engine and measure

speed.

Line pressure:

Refer to SOS, AT-166.

JUDGEMENT

•

SAT494G

line pressure

at idle and stall

OF LINE PRESSURE TEST

If line pressure does not rise, first check to make sure that

throttle wire is connected properly.

1) When line pressure while idling is low at all positions («D»,

«2», «1», «R» and «P»), the problem may be due to:

•

Wear on interior of oil pump

AT-26

TROUBLE DIAGNOSES

Pressure Testing (Cont’d)

•

Oil leakage at or around oil pump, control valve body, transmission case or governor

•

Sticking pressure regulator valve

•

Sticking pressure modifier valve

2) When line pressure while idling is low at a particular

position, check the following.

•

If oil leaks at or around low & reverse brake circuit, line

pressure becomes low in «R» position. But line pressure is

normal in «P», «D», «2» or «1» position.

3) When line pressure is high while idling, pressure regulator

valve may have stuck.

GOVERNOR

PRESSURE TESTING

1. Check AIT and engine fluid levels. If necessary, add fluid.

2.. Drive vehicle for about 10 minutes until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 — 80°C (122 — 176°F)

‘-)

~)o

(

3.

Install pressure

gauge to governor

pressure

port.

4.

5.

6.

Be

Set parking brake and block rear wheels.

Jack up front wheels.

Set selector lever in D position and drive vehicle.

careful of rotating wheels.

Front

SAT498G

Governor pressure:

•

Governor

pressure

is not generated

when vehicle

is

stopped. (front wheels are not rotating.)

•

Governor pressure rises gradually in response to vehicle

speed. (front wheel rotating speed.)

If not, check governor valve assembly. Refer to AT-36.

AT-27

•

TROUBLE DIAGNOSES

Wiring Diagram —

AT —

AT-A/T-01

(b):

:

@:

FUSE

BLOCK

(J!B)

@:

@:

@:

Refer to EL-POWER.

([@

(El06)

LHD models

RHO models

For Europe and Israel

Except@

GA engine

SR engine

l—t~’~

Y ~Next

I

y

III

Y

~ .~

~

y

(E202)

METER (00

C~INATION

OFF

INDICATOR)

OR!B

I .-

O~

OR!B ~1-

DRIB

(BID (Elan

CBID

rm

3 00 CANCEL

SOLENOID

VALVE

(E224) : @

OR!B

I

L

(El0n

OVERDRIVE

CONTROL

SWITCH

~

~

.-1

OR!B ~O

OR!B ~

/I; II

P!B@l)

E20l

I P!B ~

@ (E20n

SR

i

P!B ~

II II E203

P!B ~

<0>

~

0—1

-cz::n.

OR!B

OR!B ~

(E?6)(E203)

SR

OFF

~

~

OR!B P!B

4 ~~

TA

~o ~

•

DRIB -ea-O~

OR!B ~

ORI!B

ON

t~)

I!::iJl

@

O~

A!T CONTROL

VALVE (E223) : @

TORQUE

CONVERTER

CLUTCH

SOLENOID

VALVE

Y

~

I .-

112•61

page

L

PIB -@>Next

page

JOINT

CONNECTOR-1

B

L ~==~

~

B

B

r———————————,

Refer to last page

(Foldout page) .

~

(E224)

~GY

L

~

~~

~@D

~W

~

~

B

rn:rn:rz::rnJ

(E202),~

B

GY

CHID ,(EtOn

([@ ,(El06)

~

@J)

W@

B

ITIII:illIillIi ~

~

BR

HAT001

AT-28

TROUBLE DIAGNOSES

Wiring Diagram — AT —

(Coni’ d)

AT-A/T-02

ECM

(ECCS

CONTROL

MODULE)

LKUP

@

NEUT

I1¥Jl

3 5

11 • 1

P/B

t

LHD models

: RHO models

@: Except for Europe

and Israel

~:

GA engine for Australia

@: Except@

*1 … @ 30 , @ 115

(b):

em

G/OR

~CIID~

~-

I

G/OR

. {~P/8~

~

G/OR

lltlJr — $100 — ~

Precedlng ~

page

G/OR

CHID

c:

C

Q)

0-

o

,/

,-

r-/

~

I

2

I

I

I

Normal

:

.J

,/

/

£

I-

If throttle wire stroke is improperly adjusted the following problems may arise.

• «P1» is the throttle drum fully-open position. When «P1» is

too far in direction «T», the shift schedule will be @ in the

figure. And the kickdown range will greatly increase.

• When «P1» is too far in direction «U», the shift schedule will

be CD in the figure. And the kickdown will not occur.

,,~/~

o

Vehicle speed

SAT669H

AT-34

ON-VEHICLE SERVICE

Control Cable Installation and Adjustment

•

•

•

Move selector lever from the «P» range to the «1» range.

You should be able to feel the detents in each range.

The control cable needs adjustment in the following cases:

1) When the detents cannot be felt;

2) When the pointer indicating the range is improperly

aligned.

Always adjust control cable when it is removed from selector lever or manual shaft.

SEC. 349

Front

~

<;:::J

Selector lever assembly

4.4 — 5.9 (0.45 — 0.60, 39.1 — 52.1) Transax1,e

~

•

Cable bracket

~4.4

~

— 5.9

(0.45 • 0.60.

39.1 — 52.1)

4.4 • 5.9 (0.45 — 0.60, 39.1 — 52.1)

•

‘I

Floor panel

17.5 — 23.7 (1.8 • 2.4, 13 • 17)

Sub frame

.~

4.4 — 5.9 (0.45 • 0.60. 39.1 — 52.1)

AIT control cable assembly

~

: N.m (kg-m, in-Ib)

~

: N.m (kg-m, ft-Ib)

SAT499HA

INSTALLATION

-{‘

.~

did

Selector lever

I’y- Clamp

,I .

‘4’i»» .,)

‘OJ}

»

I

,i

Selector lever bracket Vu

7/ /

( (

. tll@:::(-c/»,/.I

»’J)!I’r.

cY’?1I /’

;

j \-.. ) ~j ‘.-It

‘.~/;,J~

‘j (,k;;. l~.: eee:::

Control cable

t;- ‘II/.f Lock nut ~i’.— l~}I’

p

u

/,<,:.~ 4.4 • 5.9 N.m

.. »

— (0.45 — 0.6 kg-m,

‘~-39.1 — 52.1 in-Ib)

A(

i t:J- .,’-‘

1. Place selector lever and manual shaft at «P» position.

2. Connect control cable to selector lever and tighten control

cable lock nut. Clamp control cable to selector lever

bracket.

,

D

I

SAT230EA

AT-35

ON-VEHICLE SERVICE

Control Cable Installation and Adjustment

(Cont’d)

3.

4.

5.

6.

7,

8.

Connect control cable to manual shaft and clamp control

cable to bracket at transaxle.

Pull control cable in the direction of the arrow shown in the

illustration by specified force.

Specified force: 6.9 N (0.7 kg, 1.5 Ib)

Return control cable in the opposite direction of the arrow

for 1.0 mm (0.039 in).

Tighten control cable lock nut.

Move selector lever from «P» position to «1» position. Make

sure that selector lever can be moved smoothly without any

sliding noise.

Apply grease to contacting areas of selector lever and control cable. Install any part removed.

SAT576E

ADJUSTMENT

1.

2.

3.

4.

5.

6.

7.

Loosen control cable lock nut at transaxle side.

Place selector lever and manual shaft at «P» position.

Pull control cable in the direction of the arrow shown in the

illustration by specified force.

Specified force: 6.9 N (0.7 kg, 1.5 Ib)

Return control cable in the opposite direction of the arrow

for 1.0 mm (0.039 in).

Tighten control cable lock nut.

Move selector lever from «P» position to «1» position. Make

sure that selector lever can be moved smoothly without any

sliding noise.

Apply grease to contacting areas of selector lever and control cable.

SAT577E

Governor Valve

1.

2.

3,

Remove air duct.

Remove governor

Remove governor

AT-36

cap snap ring.

cap,

ON-VEHICLE SERVICE

Governor Valve (Cont’d)

4.

5.

Remove governor valve assembly from transaxle.

Check governor valve assembly if necessary «DISASSEMBLY»,

AT-65.

Refer to

Inhibitor Switch Adjustment

1. Remove control cable end from manual shaft.

2. Set manual shaft in «N» position.

3.» Loosen inhibitor switch fixing bolts.

4.

Use a 4 mm (0.16 in) pin for this adjustment.

a. Insert the pin straight into the manual shaft adjustment hole.

b.

5.

6.

7.

8.

SAT580E

9.

Rotate inhibitor switch until the pin can also be inserted

straight into hole in inhibitor switch.

Tighten inhibitor switch fixing bolts.

Remove pin from adjustment hole after adjusting inhibitor

switch.

Reinstall any part removed.

Adjust control cable — Refer to «Control Cable Installation

and Adjustment», AT-35.

Check continuity of inhibitor switch — Refer to «Electrical

Components Inspection», AT-30.

Differential Side Oil Seal Replacement

1.

2.

Remove drive shaft assemblies. Refer to FA section

(«Removal»,

«FRONT AXLE — Drive Shaft»).

Remove oil seals.

AT-37

•

ON-VEHICLE SERVICE

Differential Side Oil Seal Replacement

(Cont’d)

3. Install oil seals.

• Apply ATF to oil seal surface before installing.

Converter housing side (RHS)

Transmission

case side (LHS)

SAT259EA

Transmission

case side

B

Oil

seal

Converter housing

side

•

Install oil seals so that dimensions «A» and «8» are within

specifications.

Unit: mm (in)

Oil seal

A

B

5.5 — 6.5 (0.217 — 0.256)

0.5 (0.020) or less

4. Reinstall any part removed.

A

SAT639D

AT-38

REMOVAL AND INSTALLATION

Removal

•

•

•

•

•

•

•

•

•

•

•

Remove battery and bracket.

Remove air duct.

Disconnect AIT solenoid harness connector, inhibitor switch

harness connector and speedometer

pinion harness connector.

Disconnect throttle wire at engine side.

Drain ATF.

Remove undercover and side cover.

Disconnect control cable from transaxle.

Disconnect oil cooler hoses.

Remove

«FRONT

Remove

Remove

drive shafts Refer to FA section

AXLE — Drive Shaft»).

exhaust front tube.

starter motor from transaxle.

(«Removal»,

•

Remove front and rear gussets and engine rear plate.

•

Remove bolts securing torque converter to drive plate.

Rotate crankshaft for access to securing bolts.

•

Support engine by placing a jack under oil pan.

Do not place jack under oil pan drain plug.

•

•

•

•

Support transaxle with a jack.

Remove LH and rear mountings from transaxle.

Remove bolts fixing AIT to engine.

Lower transaxle while supporting it with a jack.

AT-39

•

REMOVAL AND INSTALLATION

Installation

•

Drive plate runout

Maximum allowable runout:

Refer to EM section («Inspection»,

«CYLINDER