- Manuals

- Brands

- Stanley Manuals

ManualsLib has more than 3342 Stanley manuals

Popular Categories:

Indoor Furnishing

Lawn Mower

Power Supply

Vacuum Cleaner

Featured manuals

BM1S — Automatic 12V Battery Charger/Maintainer Manual

FATMAX SL10LEDS — Lithium LED Spotlight Manual

Accessories

Models

Document Type

3253560774073

User Manual

77-075

Operating Instructions

77-152

Manual

• Manual

FATMAX PPS200S

Instruction Manual

FORESITE Mobile Depth Sensor

Smart Manual

S150

User Manual

• User Manual

• Manual

S300

Instructions Manual

• User Manual

• Operating Instructions

• User Manual

Show all Stanley Accessories manuals

Adapter

Models

Document Type

204063

Quick Reference Manual

Fatmax SFMCB100

Original Instructions Manual

• Manual

POWERMAX 31308

Quick Start Manual

WY-06

Instruction Manual

Air Compressor

Models

Document Type

79-004

Instruction Manual And Safety Instructions

8216035SCR011

Instruction Manual

• Instruction Manual

A6BB304SCR512

Instruction Manual

AC6168

Manual

AC6359

Instruction Manual

• Manual

AC6511

User Manual

AIR KIT

Instruction Manual For Owner’s Use

AIRPRO 120

Instruction Manual

AIRPRO 120 CDC120SCA

Instruction Manual

Show all Stanley Air Compressor manuals

Air compressors

Models

Document Type

AC6359

Instruction Manual

• Manual

Analytical Instruments

Models

Document Type

Fatmax FMHT0-77421

User Manual

Fatmax TLM165S

User Manual

• User Manual

IntelliMeasure 77-018

Instruction Manual

STHT1-77366

User Manual

• User Manual

• Safety, Maintenance And Warranty

STHT77363

User Manual

TLM30

User Manual

• User Manual

TLM40

User Manual

TLM99

User Manual

• Instructions Manual

• User Manual

• Instructions Manual

• User Manual

TLM99s

User Manual

• Instructions Manual

• User Manual

• Instructions Manual

• User Manual

Show all Stanley Analytical Instruments manuals

Automobile Accessories

Models

Document Type

SIMPLE START BBC2CS

Instruction Manual

Automobile Battery Charger

Models

Document Type

TGC11

Instruction Manual

Automobile Electronics

Models

Document Type

GLPS

Instruction Manual

Battery Charger

Models

Document Type

BC15

Instruction Manual

BC1509

Instruction Manual

• Instruction Manual

BC15BS

Instruction Manual

BC209

Instruction Manual

• Instruction Manual

BC209h284504

Instruction Manual

BC2509

Instruction Manual

• Instruction Manual

BC25BS

Instruction Manual

Show all Stanley Battery Charger manuals

Blower

Models

Document Type

FATMAX SFMCBL01B

Original Instructions Manual

FATMAX SFMCBL01B (H1)

Original Instructions Manual

FATMAX SFMCBL01B-XJ

Original Instructions Manual

Fatmax SFMCBL7M1

Manual

FATMAX SFMCBLB76

Original Instructions Manual

FATMAX V20 LITHIUM ION SFMCBL730

Original Instructions Manual

SLB- 3IN1

Original Instructions Manual

SPT500

Original Instructions Manual

• Quick Start Manual

• Original Instructions Manual

Show all Stanley Blower manuals

Boiler

Models

Document Type

Tara

Installation And Operation Instructions Manual

• Installation & Operating Instructions Manual

• Installation And Operating Instructions Manual

Brush Cutter

Models

Document Type

SPS-1400

Original Instructions Manual

SPS-900

Original Instructions Manual

Cables and connectors

Models

Document Type

SXAE00013

Manual

SXAE00014

Manual

Camera Accessories

Models

Document Type

77-255

Instruction Manual

IntelliSensor Pro

User Manual

• Instruction Manual

Card Reader

Models

Document Type

909020113

Installation Manual

909028117

Installation Manual

GS3-MT

Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

GS3LFM

Installation Manual

• Installation Manual

Oneprox GS3-LF

Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

Show all Stanley Card Reader manuals

Cell Phone

Models

Document Type

MyCall Communicator 806A5601

User Manual

S241

Quick Start Manual

Cell Phone Accessories

Models

Document Type

S231

Quick Start User Manual

Chainsaw

Models

Document Type

CS05

User Manual

• User Manual

• Safety, Operation And Maintenance Manual

• User Manual

CS06

User Manual

• User Manual

• Safety, Operation And Maintenance Manual

• User Manual

CS06920

User Manual

CS06930

User Manual

Show all Stanley Chainsaw manuals

Chipper

Models

Document Type

2-Way Feed Chipper / Shredder

Owner’s Manual

• Owner’s Manual

Chippers/Shredders

Models

Document Type

CH2

Owner’s Manual

CH7

Owner’s Manual

Circuit breakers

Models

Document Type

MB256

User Manual

MB25616

User Manual

MB556

User Manual

Cleaning Equipment

Models

Document Type

FATMAX SFMCPC93

Original Instructions Manual

Fatmax SFMCPC93M1

Manual

SXPWSF001

Owner’s Operating Manual

Clock Radio

Models

Document Type

TIMERMAX TM251

Quick Start Manual

Construction Equipment

Models

Document Type

SRA 68

User Manual

SRA60

Parts Manual

• User Manual

Control Systems

Models

Document Type

GUARD STST1-71238

Manual

GUARD STST1-79226

Manual

GUARD STST320000

Manual

GUARD STST321000

Manual

Control Unit

Models

Document Type

70500

Instruction And Service Manual

• Instruction And Service Manual

• Instruction And Service Manual

• Instruction And Service Manual

70501

Instruction And Service Manual

• Instruction And Service Manual

71502

Instruction And Service Manual

• Instruction And Service Manual

71504

Instruction And Service Manual

MC521

Quick Reference Manual

MC521 Pro

Installation And Operation Manual

• Installation And Operation Manual

• Quick Reference Manual

• Installation And Operation Manual

• Installation And Operation Manual

Pellet Stove Wi-Fi Kit

Manual

Show all Stanley Control Unit manuals

Controller

Models

Document Type

204143

Installation And Operation Manual

DE-MC521

Quick Reference Manual

• Quick Reference Manual

EX5500

Installation & Configuration Manual

JUMP iT J5C09D

Instruction Manual

JUMPiT J309E

Instruction Manual

JUMPiT J309GB

Instruction Manual

Magic-Force HDFE

Quick Reference Manual

Magic-Force HDLE

Quick Reference Manual

Magic-Swing HDFE

Quick Reference Manual

Magic-Swing HDLE

Quick Reference Manual

Show all Stanley Controller manuals

Cookers

Models

Document Type

Alpha 120

Servicing Instructions

Alpha 120K

Commissioning Instructions

Alpha 150K

Servicing Instructions

• Commissioning Instructions

BRANDON 100K

Installation And Commissioning Instructions

• User Manual

• Operation Instructions Manual

• Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Instructions

BRANDON 60K

Installation And Commissioning Instructions

• User Manual

• Operation Instructions Manual

Show all Stanley Cookers manuals

Cordless Saw

Models

Document Type

FATMAX SCC500

Manual

STCT1850

Manual

STCT1860

Manual

Crimp tool

Models

Document Type

CT04

Safety, Operation And Maintenance User’s Manual

CT06

Safety And Operation Manual

• User Manual

DUBUIS BPL036

Instruction Manual

DUBUIS BPP060F

User Manual

IBC600

User Manual

• User Manual

• User Manual

PBCC40

User Manual

• User Manual

PBCC65

User Manual

• User Manual

• User Manual

PBCC85

User Manual

• User Manual

• User Manual

PBD1200

User Manual

• User Manual

PBD1201

User Manual

• User Manual

• User Manual

Show all Stanley Crimp tool manuals

Cutter

Models

Document Type

78-411

Instruction Manual

Dubuis BCP065C

Instruction Manual

DUBUS BCE025G

Instruction Manual

IBC600

User Manual

• User Manual

• User Manual

PBCC40

User Manual

• User Manual

PBCC65

User Manual

• User Manual

• User Manual

PBCC85

User Manual

• User Manual

• User Manual

PBD1200

User Manual

• User Manual

PBD1201

User Manual

• User Manual

• User Manual

Show all Stanley Cutter manuals

Cutting tool

Models

Document Type

PBCC65

User Manual

• User Manual

• User Manual

DC Drives

Models

Document Type

PD45

User Manual

• User Manual

SCH20

User Manual

• Original Instructions Manual

• Manual

SCH201

User Manual

• Original Instructions Manual

Dehumidifier

Models

Document Type

ST-12L-DH-E

Quick Start Manual

• Manual

ST-12L-DH-ME

Instruction Manual

ST-16L-DH-E

Quick Start Manual

• Manual

ST-16L-DH-ME

Instruction Manual

ST-20L-DH-E

Quick Start Manual

• Manual

ST-20L-DH-ME

Instruction Manual

ST-30L-DH-E

Manual

Show all Stanley Dehumidifier manuals

Desktop

Models

Document Type

07535

Instruction Manual

• Instruction Manual

STST98182-1

User Manual

Door

Models

Document Type

7400-Series

Quick Reference Manual

Door locks

Models

Document Type

48369 / 01 CP/BP

Quick Installation Manual

EL

Manual

ES4

Installation Instructions

ES5

Installation Instructions

Omnilock 45HOM

Installation Instructions Manual

• Installation Addendum

• Installation Template

QEL 200

User Manual

• User Manual

• Quick Start Manual

• Installation Instructions

• Quick Start Manual

• Installation Instructions

QEL 200 EL Series

User Manual

QET100 Series

Installation Instructions

Show all Stanley Door locks manuals

Door Opening System

Models

Document Type

28064

Quick Start Manual

Dura-Glide 2000AG Series

Installation Instructions, Quick Reference Manual

Dura-Glide Series

Owner’s Operation And Maintenance Manual

• Operation And Maintenance Manual

Dura-Guard Series

Owner’s Operation And Maintenance Manual

• Operation And Maintenance Manual

Dura-Max Series

Owner’s Operation And Maintenance Manual

Dura-Storm Series

Owner’s Operation And Maintenance Manual

• Operation And Maintenance Manual

Show all Stanley Door Opening System manuals

Drill

Models

Document Type

5035048724255

Original Instructions Manual

78-339

Quick Start Manual

78-407

Instruction Manual

CD10

User Manual

• User Manual

CD12

User Manual

DL07

User Manual

• Operation And Service Manual

• Service Manual

• User Manual

Show all Stanley Drill manuals

Electric Heater

Models

Document Type

EH6883

User Manual

ST-02-230-E

Operating Instructions Manual

• Operating Instructions Manual

• Instruction Manual

• Manual

• Manual

• Instruction Manual

• Manual

• Manual

ST-02-240-E

Operating Instructions Manual

• Operating Instructions Manual

• Instruction Manual

• Manual

• Manual

• Instruction Manual

• Manual

• Manual

ST-03-230-E

Operating Instructions Manual

• Operating Instructions Manual

• Instruction Manual

• Manual

• Manual

• Instruction Manual

• Manual

• Manual

ST-033-230-E

Operating Instructions Manual

• Operating Instructions Manual

• Instruction Manual

• Manual

• Manual

• Instruction Manual

• Manual

• Manual

ST-05-400-E

Operating Instructions Manual

• Operating Instructions Manual

• Instruction Manual

• Manual

• Manual

• Instruction Manual

• Manual

• Manual

ST-09-400-E

Operating Instructions Manual

• Operating Instructions Manual

• Instruction Manual

• Manual

• Manual

• Instruction Manual

• Manual

• Manual

ST-302-231-E

Instruction Manual

ST-303-231-E

Instruction Manual

ST-305-401-E

Instruction Manual

Show all Stanley Electric Heater manuals

Engine

Models

Document Type

HV18

User Manual

• Safety, Operation & Maintenance

OHV Series

Manual

Extender

Models

Document Type

Simple Start

Quick Start Manual

Simple Start P2G7S

Quick Start Manual

SSLION

Instruction Manual

Fan

Models

Document Type

146796099

Instruction Manual

146796199

Instruction Manual

655302

Operation And Maintenance Manual

655702

Operation And Maintenance Manual

FATMAX SFMCE001

Original Instructions Manual

FT10

Installation & Commissioning Instructions

ST-12F

Instruction Manual

ST-12F-DDF-E

User’s Manual And Operating Instructions

• User’s Manual And Operating Instructions

• User’s Manual And Operating Instructions

Show all Stanley Fan manuals

Fire Alarms

Models

Document Type

SCSS-700

Installation & Operation Manual

Fitness Equipment

Models

Document Type

Sprinter 190

Manual

Flashlight

Models

Document Type

95-112

Manual

95-148

Manual

95-155

Manual

• Manual

BARFLEX BF0109

Instruction Manual

• Instruction Manual

• Instruction Manual

BARFLEX BF0109CA

Instruction Manual

FatMax 95-154

Quick Start Manual

FatMax FMHT72397

Instructions

Show all Stanley Flashlight manuals

Flood Light

Models

Document Type

LAMPMAX DELUXE

Quick Start Manual

Garage Door Opener

Models

Document Type

U-INSTALL

Owner’s Manual

• Owner’s Manual

Garbage Disposal

Models

Document Type

HS3000

Service Manual

Gas Heater

Models

Document Type

ST-11P-CPH-EC

User’s Manual And Operating Instructions

ST-11P-CPH-EU

User’s Manual And Operating Instructions

ST-11T-CPH-E

User’s Manual And Operating Instructions

• User’s Manual And Operating Instructions

ST-14A-CH-E

Instruction Manual

• Manual

• Instructions Manual

ST-14S-CH-E

Instruction Manual

• Manual

• Instructions Manual

Gate Opener

Models

Document Type

Dura-Glide 2000

Installation And Operation Manual

Dura-Glide 3000

Installation And Operation Manual

Dura-Glide 5200

Installation And Operation Manual

Dura-Glide 5300

Installation And Operation Manual

Dura-Guard

Installation And Operation Manual

Dura-Max 5400 Series

Installation And Operation Manual

Dura-Storm

Installation And Operation Manual

DuraCare 7500A TL-FBO

Installation And Operation Manual

ProCare 8300A

Installation And Operation Manual

Gateway

Models

Document Type

GW1200

Installation & Configuration Manual

SHX-GTW

Installation Instructions

Generators

Models

Document Type

SIG 3200

Original Instructions Manual

Glue Gun

Models

Document Type

6-GR25

Original Instructions Manual

FATMAX STHT6-70416

Original Instructions Manual

GPS

Models

Document Type

Hugs

User Manual

Kisses

User Manual

Grinder

Models

Document Type

FATMAX FMC761

Original Instructions Manual

• Original Instructions Manual

FATMAX FMC761M2

Original Instructions Manual

FatMax FME820

Instruction Manual

FatMax FME841

Original Instructions Manual

FATMAX FMEG125V

Manual

FATMAX FMEG210

Manual

• Original Instructions Manual

FATMAX FMEG220

Manual

• Original Instructions Manual

Show all Stanley Grinder manuals

Hand Mixer

Models

Document Type

SDR1400

Original Instructions Manual

• Manual

• Original Instructions Manual

• Instruction Manual

• Original Instructions Manual

Handsets

Models

Document Type

AudioHS-QSG

Installation And Programming

Headlamp

Models

Document Type

HL1S

Instruction Manual

HL2PKS

Instruction Manual

HL2S

Instruction Manual

HLWAKS

Instruction Manual

HLWAKSL

Manual

Heat Pump

Models

Document Type

Solis ECO

Operation And Installation Manual

Heat Pump Accessories

Models

Document Type

WSL141

Manual For Installation, Operation And Maintenance

WSL142

Manual For Installation, Operation And Maintenance

Heater

Models

Document Type

5900

User Manual

657888110095

Manual

675900

Manual

957071

Instruction Manual

Show all Stanley Heater manuals

Impact Driver

Models

Document Type

78-342

Quick Start Manual

78-343

Instruction Manual

AUTOMATIVE STMT70116-8

Quick Start Manual

Fat Max FMC041

Original Instructions Manual

Fatmax FMC040

User Manual

• Instruction Manual

FatMax FMC645

User Manual

• Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

Show all Stanley Impact Driver manuals

Indoor Fireplace

Models

Document Type

Argon Built 3 Sided

Manual

Argon Built In ARBI100

Installation And Operating Instructions Manual

Argon Built In ARBI130

Installation And Operating Instructions Manual

Argon Cube

Manual

Argon NMARWH110

Manual

Argon NMARWH140

Manual

Argon NMARWH90

Manual

Argon Wall Mounted ARWH110

Installation And Operating Instructions Manual

Argon Wall Mounted ARWH140

Installation And Operating Instructions Manual

Argon Wall Mounted ARWH200

Installation And Operating Instructions Manual

Show all Stanley Indoor Fireplace manuals

Indoor Furnishing

Models

Document Type

DELUXE CLOSET SYSTEM

Assembly Instructions Manual

H5CHSBK

Use And Care Manual

Show all Stanley Indoor Furnishing manuals

Industrial Equipment

Models

Document Type

71502

Instruction And Service Manual

• Instruction And Service Manual

AV 10

Instruction And Service Manual

• Assembly Instructions Manual

AV 5

Instruction And Service Manual

• Assembly Instructions Manual

AVDEL Avseal II 73200

Assembly Instructions Manual

AVDEL Avseal II PB2500

Assembly Instructions Manual

AVDEL Avseal II PB3400

Assembly Instructions Manual

AVDEL Avseal II ProSet XT

Assembly Instructions Manual

EP30200

User Manual

PP10

User Manual

QED100

Quick Start Manual

Show all Stanley Industrial Equipment manuals

Inverter

Models

Document Type

E-SG 2200

Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

E-SG 4000

Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

FATMAX PCI140CA

Instruction Manual

HP1

Safety, Operation And Maintenance Manual

Show all Stanley Inverter manuals

IP Access Controllers

Models

Document Type

PAC iPAC

Quick Start Manual

Keypad

Models

Document Type

40HZ

Manual

9KZ

Manual

EXZ

Manual

KEYPAD EZ LOCKS

Brochure & Specs

Kitchen Appliances

Models

Document Type

BRANDON

Operation Instructions Manual

• Operation Instructions Manual

BRANDON 100K

Installation And Commissioning Instructions

• User Manual

• Operation Instructions Manual

• Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Instructions

BRANDON 80K

Installation And Commissioning Instructions

• User Manual

• Operation Instructions Manual

• Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Instructions

BRANDON DHW

Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Manual

BRANDON DHW OIL

Operation Instructions Manual

BRANDON DRY

Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Manual

BRANDON DRY OIL

Operation Instructions Manual

Brandon OCD

User Instructions

COMERAGH — 50

Operating Instructions Manual

• Instruction Manual

• Installation And Operation Instructions Manual

DHW

Operating Instructions Manual

Show all Stanley Kitchen Appliances manuals

Label Maker

Models

Document Type

HeavyDuty Labeler 1150DX

Manual

HeavyDuty Labeler ST-1150

Manual

ST-1150

User Manual

Laminate Trimmer

Models

Document Type

ST55

Manual

• Manual

• Original Instructions Manual

• Instruction Manual

Laser Level

Models

Document Type

77-121

Manual

77-189

Instruction Manual

CL2XTi

Manual

CLLi

Instructions For Use Manual

CROSS 90

User Manual

• Instructions Manual

Cubix STHT77340

User Manual

Fat Max S2

Instruction Manual

Fat Max S2XL

Instruction Manual

• Instruction Manual

FatMax AL32

Manual

Show all Stanley Laser Level manuals

Lawn and Garden Equipment

Models

Document Type

1303W

Quick Start Manual

BDS6520

Instruction Manual

EA08

User Manual

• Safety, Operation & Maintenance

• User Manual

FATMAX SFMSTB930

Original Instructions Manual

STR-4 IN 1

Original Instructions Manual

Lawn Mower

Models

Document Type

100″ Tow BEHIND MOWER

Owner’s Manual

100TS

Owner’s Manual

• Owner’s Manual

309311x692A

Instruction Book

36BDS

Owner’s Manual

36BS

Owner’s Manual

36FDS

Owner’s Manual

• Owner’s Manual

36FS

Owner’s Manual

• Owner’s Manual

Show all Stanley Lawn Mower manuals

Light Fixture

Models

Document Type

Fatmax FMHT81507-1

Instruction Manual

Fatmax FMHT81508-1

Instruction Manual

Lighting Equipment

Models

Document Type

FT448

Instruction Manual

LIGHTTIMER SELECT TWIN TM501

Instructions Manual

PSL1000S

Instruction Manual

SB01AL

Instruction Manual

SCT12

Manual

Locks

Models

Document Type

203820

Installation Instructions Manual

3 Series

Service Manual

83KM-93KM

Installation Instructions Manual

85KM-95KM

Installation Instructions Manual

9K Series

Manual

BEST ACCESS SYSTEMS 45HM IDH Max

Manual

BEST ACCESS SYSTEMS 45HM Series

Quick Start Manual

GS3-MT PIN

Installation Manual

GS3PIN

Installation Manual

OmniLock

Illustrated Parts Catalog

Show all Stanley Locks manuals

Measuring Instruments

Models

Document Type

0-77-030

User Manual

• Manual

4V360H

Manual

77-030

Manual

BRANDON OIL MK3

Installation Manual

CL2i

User Manual

Compulevel

User Manual

CROSS 90

User Manual

• Instructions Manual

Fatmax FMHT77356

Manual

Fatmax FMHT77357

Manual

Show all Stanley Measuring Instruments manuals

Media Converter

Models

Document Type

PC1A09

Instruction Manual

PC509

Instruction Manual

PC809

Instruction Manual

Medical Equipment

Models

Document Type

AeroScout EX5210R

Installation & Configuration Manual

Bed-Check Vr

Quick Programming Manual

M200

Setup & User Manual

T14

User Manual

Mixer

Models

Document Type

Fatmax FME190

Original Instructions Manual

• Original Instructions Manual

SDR1400

Original Instructions Manual

• Manual

• Original Instructions Manual

• Instruction Manual

• Original Instructions Manual

Monitor

Models

Document Type

UMP 91621

User Manual

Multimeter

Models

Document Type

Fatmax FMHT77419

User Manual

STHT0-77364

User Manual

Nail Gun

Models

Document Type

76001

Service Manual

• Original Instruction

• Instruction Manual

• Original Instruction

• Instruction Manual

• Instruction Manual

• Instruction Manual

76003

Service Manual

• Instruction Manual

• Instruction Manual

• Instruction Manual

APC-2IN1

Technical Data Manual

APC-BN

Technical Data Manual

APC-FN

Technical Data Manual

Bostitch BT1855

Original Instructions Manual

BOSTITCH F21PL

Original Instructions Manual

BOSTITCH F28WW

Original Instructions Manual

BOSTITCH F33PT

Original Instructions Manual

BOSTITCH F33PTSM

Original Instructions Manual

Show all Stanley Nail Gun manuals

Other

Models

Document Type

ProSet XT3

Service Manual

• Instruction Manual

• Instruction Manual

• Instruction Manual

• Instruction Manual

• Instruction Manual

ProSet XT4

Instruction Manual

• Instruction Manual

• Instruction Manual

• Instruction Manual

• Instruction Manual

• Service Manual

TA54

User Manual

• Safety, Operation & Maintenance

Oven

Models

Document Type

BRANDON DHW

Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Manual

BRANDON DRY

Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Manual

Paint Sprayer

Models

Document Type

160123XSTN

Instruction Manual For Owner’s Use

161132XSTN

Instruction Manual For Owner’s Use

Pellet stove

Models

Document Type

FUSION PELLET STOVE

Operating & Installation Manual

Pipe cleaners

Models

Document Type

FATMAX V20 LITHIUM ION SFMCGA75

Original Instructions Manual

FATMAX V20 LITHIUM ION SFMCGA75M1

Original Instructions Manual

Planer

Models

Document Type

FatMax FME630

Original Instructions Manual

• Manual

Fatmax KFFMEW630

Original Instructions Manual

STEL360

User Manual

STPP7502

Instruction Manual

• Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

Show all Stanley Planer manuals

Pole Saw

Models

Document Type

CS25

User Manual

• User Manual

• User Manual

CS25112P

User Manual

CS2581106

User Manual

CS25812

User Manual

CS258812

User Manual

CS28

User Manual

• User Manual

• User Manual

Show all Stanley Pole Saw manuals

Portable Generator

Models

Document Type

AL35

Safety, Operation And Maintenance User’s Manual

FATMAX EVO160 TIG LIFT

Manual

G2250S

Owner’s Manual

• Owner’s Manual

G3250S

Owner’s Manual

• Owner’s Manual

G5000S

Owner’s Manual

• Owner’s Manual

• Owner’s Manual

G8000S

Owner’s Manual

• Owner’s Manual

• Owner’s Manual

Show all Stanley Portable Generator manuals

Power distribution unit

Models

Document Type

Fatmax PPRH5DS

Instruction Manual

Power Hammer

Models

Document Type

FATMAX SFMEH230

Original Instructions Manual

• Original Instructions Manual

FATMAX SFMEH230K-QS

Original Instructions Manual

LaBounty MRP

Safety, Operation & Maintenance Instructions

STHM10

Original Instructions Manual

• Original Instructions Manual

• Instruction Manual

STHM10K

Original Instructions Manual

STHM5

Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

• Original Instruction

• Manual

Power Screwdriver

Models

Document Type

Fatmax FMC011S

Manual

Fatmax FMC021

Manual

FATMAX FMC626C2K

Original Instructions Manual

FATMAX FMC627

Original Instructions Manual

• Manual

FATMAX FMHT66719

Original Instructions Manual

FATMAX KFMCD011

Original Instructions Manual

• Original Instructions Manual

• Original Instructions Manual

FATMAX KFMCD011S2

Original Instructions Manual

• Original Instructions Manual

Fatmax SCD718

Original Instructions Manual

• Original Instructions Manual

Show all Stanley Power Screwdriver manuals

Power Strips

Models

Document Type

POWERMAX 6

Instructions

Power Supply

Models

Document Type

FATMAX PP1DCS

Instruction Manual

FatMax PPRH5KL

Quick Start Manual

FATMAX PPRH7DS

Instruction Manual

GT09

Safety, Operation And Maintenance User’s Manual

GT13

Safety, Operation And Maintenance User’s Manual

J5C09D

Instruction Manual

J7C09D

Instruction Manual

PLUGBANK 6

Manual

PPRH5

Instruction Manual

• Instruction Manual

Show all Stanley Power Supply manuals

Power Tool

Models

Document Type

00496014

Instruction And Service Manual

031312004

Safety, Operation & Maintenance

07287

Instruction And Service Manual

07530

Instruction And Service Manual

• Instruction And Service Manual

07531

Instruction And Service Manual

• Instruction And Service Manual

07532

Instruction And Service Manual

• Instruction And Service Manual

07536

Instruction And Service Manual

• Instruction And Service Manual

07537-00200

Instruction And Service Manual

150703XSTN

Instruction Manual For Owner’s Use

150704XSTN

Instruction Manual For Owner’s Use

Show all Stanley Power Tool manuals

Power Tool Accessories

Models

Document Type

S3007

Operating Instructions

Power Tools

Models

Document Type

0753 MKII

Instruction And Service Manual

07530

Instruction And Service Manual

• Instruction And Service Manual

07531

Instruction And Service Manual

• Instruction And Service Manual

07532

Instruction And Service Manual

• Instruction And Service Manual

73200

Instruction And Service Manual

• Instruction And Service Manual

• Instruction And Service Manual

76001

Service Manual

• Original Instruction

• Instruction Manual

• Original Instruction

• Instruction Manual

• Instruction Manual

• Instruction Manual

76002

Original Instruction

• Instruction Manual

• Original Instruction

• Instruction Manual

• Instruction Manual

• Instruction Manual

EZM1000

Instruction And Service Manual

• Instruction And Service Manual

Show all Stanley Power Tools manuals

Pressure Washer

Models

Document Type

BXPW1300E

Original Instructions Manual

BXPW1300PE

Original Instructions Manual

BXPW1400E

Original Instructions Manual

BXPW1400PE

Original Instructions Manual

BXPW1500E

Original Instructions Manual

BXPW1500PE

Original Instructions Manual

BXPW1600E

Original Instructions Manual

BXPW1600PE

Original Instructions Manual

BXPW1700E

Original Instructions Manual

BXPW1700PE

Original Instructions Manual

Show all Stanley Pressure Washer manuals

Printer

Models

Document Type

MODEL 1

User Manual

STDG5006

Original Instructions Manual

Projector Accessories

Models

Document Type

PJMM-2465C

Installation Manual

Radio

Models

Document Type

FatMax FMC770

Original Instructions Manual

• Manual

FATMAX FMCR001

Manual

Ranges

Models

Document Type

BRANDON 100K

Installation And Commissioning Instructions

• User Manual

• Operation Instructions Manual

• Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Instructions

BRANDON 60K

Installation And Commissioning Instructions

• User Manual

• Operation Instructions Manual

BRANDON 80K

Installation And Commissioning Instructions

• User Manual

• Operation Instructions Manual

• Installation And Commissioning Instructions

• Operation Instructions Manual

• Installation And Commissioning Instructions

DONARD 60K

Installation And Operating Instructions Manual

Errigal and

Installation And Operating Instructions Manual

• Instruction Manual

• Installation And Operating Instructions Manual

• Assembly, Installation And Operating Instructions

• Training Manual

Woodburning Range and

Installation And Operating Instructions Manual

• Assembly, Installation And Operating Instructions

Receiver

Models

Document Type

FATMAX FMHT1-77359

User Manual

FatMax FMHT1-77360

Manual

Remote Control

Models

Document Type

31166

Quick Start Manual

31184

Quick Start Manual

51180

Instructions

• Quick Start Manual

51186

Quick Start Manual

51192

Installation & Pairing

56316

Quick Start Manual

56322

Quick Start Manual

56325

Manual

56326

Quick Start Manual

58325-AHR

Manual

Show all Stanley Remote Control manuals

Remote Starter

Models

Document Type

350 AMP

Instruction Manual

FatMax

Instruction Manual

• Instruction Manual

• Instruction Manual

fatmax 700

Instruction Manual

Fatmax J7C5

Instruction Manual

J309

Instruction Manual

• Instruction Manual

• Instruction Manual

• Instruction Manual

J45C09

Instruction Manual

J45TK

Manual

Show all Stanley Remote Starter manuals

Rfid Systems

Models

Document Type

EX5200

Deployment Manual

PAC iEVO Series

Quick Start Manual

Rivet Tools

Models

Document Type

07535

Instruction Manual

• Instruction Manual

73200

Instruction And Service Manual

• Instruction And Service Manual

• Instruction And Service Manual

73482

Instruction And Service Manual

• Instruction And Service Manual

73483

Instruction And Service Manual

74202

Service Manual

• Service Manual

• Instruction Manual

76005

Instruction Manual

AV 20

Instruction And Service Manual

• Instruction And Service Manual

AV 25

Instruction And Service Manual

Show all Stanley Rivet Tools manuals

Rotary Hammer

Models

Document Type

Fatmax FMCD900

Original Instructions Manual

Fatmax FMER524

Manual

Fatmax SFMCH900 Series

Original Instructions Manual

• Manual

• Original Instructions Manual

Fatmax SFMCH900B

Original Instructions Manual

Show all Stanley Rotary Hammer manuals

Safety Equipment

Models

Document Type

DE-MC521

Quick Reference Manual

• Quick Reference Manual

Sander

Models

Document Type

78-409

Quick Start Manual

FAT MAX FMEW214

Manual

FAT MAX KFFMEW210

Manual

FAT MAX SFMEE500

Original Instructions Manual

FATMAX FMCW210

Original Instructions Manual

• Original Instructions Manual

FATMAX FMCW220

Original Instructions Manual

• Original Instructions Manual

Fatmax FMEW204

Original Instructions Manual

• Original Instructions Manual

Show all Stanley Sander manuals

Saw

Models

Document Type

CO23

User Manual

CO23341

User Manual

CO25

Service Manual

• User Manual

• User Manual

CO25141

User Manual

CO2514101

Service Manual

CO25541

User Manual

CO2554101

Service Manual

COV10 V SERIES

User Manual

Show all Stanley Saw manuals

Scanner

Models

Document Type

GS3-MT

Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

Oneprox GS3-LF

Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

• Installation Manual

Security Sensors

Models

Document Type

FATMAX FMHT77652

User Manual

FATMAX FMHT77653

User Manual

IntelliLaser Pro

Instruction Manual

• Instruction Manual

• User Manual

INTELLILASER PRO 0-77-260

User Manual

IntelliSensor Pro

User Manual

• Instruction Manual

K2

Manual

LD100

User Manual

QED300

Installation Instructions Manual

• Installation Instructions

• Manual

S100

User Manual

• User Manual

S50

User Manual

Show all Stanley Security Sensors manuals

Security System

Models

Document Type

BEST SSS-SEDA

Manual

Easikey 250

User And Installation Manual

SCSS-700VS

Installation & Operation Manual

Shelter FOB 9KX

Operating Instructions

VIP Series

Installation & Operation Manual

Server

Models

Document Type

ACS

Quick Start Manual

Snow Blower

Models

Document Type

30SS

Owner’s Manual

• Owner’s Manual

36SS

Owner’s Manual

• Owner’s Manual

• Owner’s Manual

45SS

Owner’s Manual

• Owner’s Manual

• Owner’s Manual

SPT-163-560

Original Instructions Manual

SPT-182-570

Original Instructions Manual

• Original Instructions Manual

Show all Stanley Snow Blower manuals

Speakers

Models

Document Type

FatMax FMC772B

Original Instructions Manual

• Original Instructions Manual

MOBILE

Quick Start User Manual

Spotlight

Models

Document Type

FatMax

Instruction Manual

• Instruction Manual

• Instruction Manual

FATMAX SL10LEDS

Instruction Manual

• User Manual

FL5W10

Instruction Manual

• Instruction Manual

FL5W15S

Instruction Manual

HID0109

Instruction Manual

HIDC10

Instruction Manual

HIDLIS

Manual

Show all Stanley Spotlight manuals

Staple Gun

Models

Document Type

TR35

Quick Start Manual

Stove

Models

Document Type

0063AU5289

Assembly, Installation And Operation Instructions

Aoife

Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

• User Instructions

Ardmore

Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

ARDMORE HPB

Manual

Argon Arranmore

Installation And Operating Instructions Manual

Argon Bailey

Installation And Operating Instructions Manual

Show all Stanley Stove manuals

Stud Sensor

Models

Document Type

3253560775889

User Manual

IntelliSensor 77-110

Instruction Manual

S100

User Manual

• User Manual

S150

User Manual

• User Manual

• Manual

S200

User Manual

S300

Instructions Manual

• User Manual

• Operating Instructions

• User Manual

STHT77587

User Manual

• Manual

Show all Stanley Stud Sensor manuals

Swimming Pool Vacuum

Models

Document Type

PoolTec

Owner’s Manual

• Owner’s Manual

PoolTec 28817

Owner’s Manual

Switch

Models

Document Type

51180

Instructions

• Quick Start Manual

ECO Pro

Quick Reference Manual

Thermometer

Models

Document Type

Fatmax FMHT0-77422

User Manual

• Original Instructions Manual

STHT0-77365

User Manual

• User Manual

Tiller

Models

Document Type

SGT-25-450-H

Original Instructions Manual

SGT-25-450-V

Original Instructions Manual

SGT-51-820-H

Original Instructions Manual

Timer

Models

Document Type

31250

Quick Start Manual

31251

Quick Start Manual

38424

Quick Start Manual

51215

Quick Start Manual

56470

Quick Start Manual

56471

Quick Start Manual

DR-1589

Manual

GS-302

Operating Instructions Manual

LIGHTTIMER SELECT TWIN

Manual

PLUGBANK 3 SELECT

Operating Instructions Manual

Show all Stanley Timer manuals

Tool Storage

Models

Document Type

FatMax XTREME

User Manual

Garage Workshop T3

Assembly Instructions Manual

Show all Stanley Tool Storage manuals

Tools

Models

Document Type

07536

Instruction And Service Manual

• Instruction And Service Manual

07536-02100

Instruction And Service Manual

150

Quick Start Manual

160173XSTN

Instruction Manual For Owner’s Use

204018

Quick Reference Manual

55

Quick Manual

• How To Use Manual

65AT

Manual

70500

Instruction And Service Manual

• Instruction And Service Manual

• Instruction And Service Manual

• Instruction And Service Manual

Show all Stanley Tools manuals

Tractor

Models

Document Type

MHP3

User Manual

• User Manual

Trimmer

Models

Document Type

Fatmax SFMCHTB866

Original Instructions Manual

FATMAX SFMCPH845

Original Instructions Manual

Fatmax SFMCST933

Instructions Manual

• Original Instructions Manual

FATMAX SFMCSTB933

Original Instructions Manual

• Original Instructions Manual

FATMAX V20

Original Instructions Manual

FATMAX V20 SFMCST933

Instructions Manual

FATMAX V60

Original Instructions Manual

SFMCSTB963

Original Instructions Manual

Show all Stanley Trimmer manuals

TV Accessories

Models

Document Type

TTL-6644TS

Installation Manual

TV Mount

Models

Document Type

TLR-EC3215T

Installation Manual

TLS-120T

Installation Manual

TLS-210S

Installation Manual

TLX-105FM

Installation Manual

TMS-DS1113T

Installation Manual

Ultrasonic Jewelry Cleaner

Models

Document Type

SXPW0101

Owner’s Operating Manual

Vacuum Cleaner

Models

Document Type

199-4375-2

Owner’s Manual

8111007W

Owner’s Manual

8210413B

Owner’s Manual

BXVC15PE

Manual

BXVC20PE

Manual

BXVC20PTE

Manual

BXVC20XE

Manual

BXVC20XTE

Manual

BXVC25PDE

Manual

BXVC30PDE

Manual

Show all Stanley Vacuum Cleaner manuals

Vibratory rammers & tampers

Models

Document Type

TA54

User Manual

• Safety, Operation & Maintenance

TA54103

Safety, Operation & Maintenance

TA54603

Safety, Operation & Maintenance

TA54603A

Safety, Operation & Maintenance

Water Pump

Models

Document Type

76501-02000

Manual

76501-02500

Manual

76502-02000

Manual

76502-02500

Manual

76503-02000

Manual

76503-02500

Manual

76504-02000

Manual

76504-02500

Manual

76505-02000

Manual

76505-02500

Manual

Show all Stanley Water Pump manuals

Welding Accessories

Models

Document Type

E-Protection 2000 E

User Manual

E-Protection 2000 E 11

User Manual

PC1T09

Instruction Manual

Welding System

Models

Document Type

460081

User Manual

EPX10

User Manual

• Safety, Operation And Maintenance User’s Manual

FATMAX TIG LIFT

User Manual

GOLDEN ARC MINI

User Manual

IPER E181

User Manual

MIKROMIG

User Manual

RW30110

User Manual

RW30112

User Manual

RW30120

User Manual

Show all Stanley Welding System manuals

Wood Router

Models

Document Type

SRR1200

Original Instructions Manual

• Original Instructions Manual

• Instruction Manual

• Original Instructions Manual

SRR1200-RU

Original Instructions Manual

Wood stove

Models

Document Type

Aoife

Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

• User Instructions

Errigal and

Installation And Operating Instructions Manual

• Instruction Manual

• Installation And Operating Instructions Manual

• Assembly, Installation And Operating Instructions

• Training Manual

K1200

Installation And Operating Instructions Manual

• Instruction Manual

K1700

Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

• Instruction Manual

K2300

Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

• Instruction Manual

Lismore

Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

• Installation And Operating Instructions Manual

Solis F1100 Panoramic

Installation And Operating Instructions Manual

Work Light

Models

Document Type

7629101430

Instruction Manual

7629104430

Instruction Manual

7634802430

Instruction Manual

BARFLEX BF0109

Instruction Manual

• Instruction Manual

• Instruction Manual

BF01AL

Instruction Manual

DR-1577

Operator’s Manual

FATMAX FMCL001B

Original Instructions

FATMAX SFMCL020

Original Instructions Manual

Show all Stanley Work Light manuals

- Home

- Stanley

Количество руководств по эксплуатации : 202

Инструкции по эксплуатации

Укажите здесь торговую марку и тип

Количество руководств по эксплуатации : 202

В настоящее время вы находитесь на странице с руководствами . Выберите одну из категорий продуктов, чтобы быстро найти нужное руководство . Не удалось найти нужный продукт ? Тогда попробуйте вбить в строку поиска и модель, чтобы найти нужное руководство . На ManualsPDF.ru в настоящее время имеется 202 руководств , разделенных на 28. Самые популярные категории продуктов :

- Компрессоры

- Зарядные устройства

- Лазерные указки

Самые популярные продукты из на сегодня:

- Stanley BC15BS

- Stanley SXVC30XTDE

- Stanley TLM30

Стэнли Логистикс, Инк., работает как глобальная компания, предоставляющая финансовые услуги. Фирма предоставляет инвестиционно-банковские продукты и услуги своим клиентам и заказчикам, включая корпорации, правительства, финансовые учреждения и частных лиц. Их официальный webсайт Стэнли.com.

Каталог руководств пользователя и инструкций для продуктов Stanley можно найти ниже. Продукция Stanley запатентована и зарегистрирована под торговыми марками Стэнли Логистикс, Инк.

Контактная информация:

Адрес: Morgan Stanley & Co. 1 International Place, 13th Floor Boston, MA 02110

Найти

3Gal (11.5Liter) WET/DRY VACUUM) OWNER’S MANUALIMPORTANT: READ THIS OPERATOR’S MANUAL BEFORE USING! Manufactured in China Toll-free helpline for replacement parts: 1-888-899-0146 © 2015 Alton Industry Ltd. Group – All Rights Reserved PRODUCT SPECIFICATIONS Power 220V/50/60Hz/ 900W Motor By-Pass, Single Stage Tank Capacity 3 Gallon Hose 1-1/4 in. x 5 ft. Power cord 10 ft. Length …

Подробнее “STANLEY SL18136 Wet-Dry Vacuum Owner’s Manual”

STANLEY SL18115 Пылесос на 5 галлонов Руководство пользователя ХАРАКТЕРИСТИКИ ИЗДЕЛИЯ Питание: 120 В / 60 Гц / 7 А Двигатель: байпас, одинарный Stage Емкость резервуара: 5 галлонов. Шланг: 1-1/4 дюйма x 5 футов. Шнур питания: SJTW18AWG / 10 футов. Длина ПРЕДУПРЕЖДЕНИЕ. Используйте только удлинители, предназначенные для использования вне помещений. Удлинители в плохом…

Подробнее «Руководство по эксплуатации пылесоса STANLEY SL18115 на 5 галлонов»

STANLEY SL18402-8B Пылесос для сухой и влажной уборки объемом 8 галлонов Руководство пользователя ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ ИЗДЕЛИЯ Мощность: 120 В / 60 Гц / 10 А Двигатель: Single Stage Емкость резервуара: 8 галлонов. Шланг: 1-7/8 дюйма x 6 футов. Шнур питания: SJTW18AWG / 10 футов. Длина ПРЕДУПРЕЖДЕНИЕ. Используйте только удлинители, предназначенные для использования вне помещений. Удлинители в…

Подробнее «Руководство пользователя пылесоса для сухой и влажной уборки STANLEY SL18402-8B на 8 галлонов»

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ И ОБСЛУЖИВАНИЮ ОРИГИНАЛЬНАЯ ИНСТРУКЦИЯ Гидропневматический электроинструмент Инструмент для заклепочных гаек — 74200 ОРИГИНАЛЬНАЯ ИНСТРУКЦИЯ 74200 Инструмент с резьбовой вставкой © 2021 Stanley Black & Decker inc. Все права защищены. Предоставленная информация не может быть воспроизведена и/или обнародована каким-либо образом и с помощью любых средств (электронных или механических) без предварительного явного и письменного разрешения от…

Подробнее «Руководство по эксплуатации инструмента с резьбовой вставкой STANLEY 74200»

Инструкция по эксплуатации ударной отвертки STANLEY SBI810 Overview Рисунок Инструкции Использование по назначению Ваш бесщеточный ударный шуруповерт STANLEY SBI810 предназначен для завинчивания и завинчивания гаек. Этот прибор предназначен для профессиональных и частных непрофессиональных пользователей. Инструкции по технике безопасности Общие предупреждения по безопасности при работе с электроинструментом Внимание! Прочтите все предупреждения о безопасности, инструкции, иллюстрации и технические характеристики, прилагаемые к этому …

Подробнее «Руководство по эксплуатации ударной отвертки STANLEY SBI810»

STANLEY 74200 Инструмент для установки заклепок-гаек Информация о продукте Инструмент для заклепок-гаек – 74200 представляет собой гидропневматический инструмент, предназначенный для установки заклепок-гаек. Инструмент имеет следующие характеристики: Спецификация установочного инструмента Вес: 2 кг (4.4 фунта) Ход: 7 мм (0.28 дюйма) Давление воздуха: 6–8 бар (87–116 фунтов на кв. дюйм) Гидравлическое давление: 30–80 бар …

Подробнее «Инструкция по эксплуатации инструмента для изготовления заклепочных гаек STANLEY 74200»

STANLEY ESAFOR MK II 74290 Гидропневматический электроинструмент © 2021 Stanley Black & Decker inc. Все права защищены. Предоставленная информация не может быть воспроизведена и/или обнародована каким-либо образом и с помощью любых средств (электронных или механических) без предварительного письменного разрешения от STANLEY Engineered Fastening. Предоставленная информация основана на…

Подробнее «Руководство пользователя гидропневматического электроинструмента STANLEY ESAFOR MK II 74290»

Гидравлические/пневматические заклепочные инструменты STANLEY EZM1000 ВВЕДЕНИЕ Предоставленная информация не может быть воспроизведена и/или обнародована каким-либо образом и с помощью любых средств (электронных или механических) без предварительного явного и письменного разрешения от STANLEY Engineered Fastening. Предоставленная информация основана на данных, известных на момент внедрения этого продукта. …

Подробнее «Руководство пользователя гидравлических/пневматических заклепочных инструментов STANLEY EZM1000»

Гидропневматический электроинструмент 74200. Руководство пользователя. РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ И ОБСЛУЖИВАНИЮ. ОРИГИНАЛЬНАЯ ИНСТРУКЦИЯ. Гидропневматический электроинструмент 74200. Все права защищены. Предоставленная информация не может быть воспроизведена и/или обнародована каким-либо образом и с помощью любых средств (электронных или механических)…

Подробнее «Руководство пользователя гидропневматического электроинструмента STANLEY 74200»

Гидропневматический силовой модуль 71501 Руководство пользователя Гидропневматический силовой модуль 71501 © STANLEY Black & Decker, 2021 г. Все права защищены. Предоставленная информация не может быть воспроизведена и/или обнародована каким-либо образом и с помощью любых средств (электронных или механических) без предварительного письменного разрешения от STANLEY Engineered Fastening. Представленная информация основана на…

Подробнее «Руководство пользователя гидропневматического силового модуля STANLEY 71501»

ENGLISH (Original Instructions)

SM18

English

French

Russian

Ukrainian

Turkish

ةيبرعلا

14

27

42

61

77

107

ENGLISH (Original Instructions)

2

0000 00-00

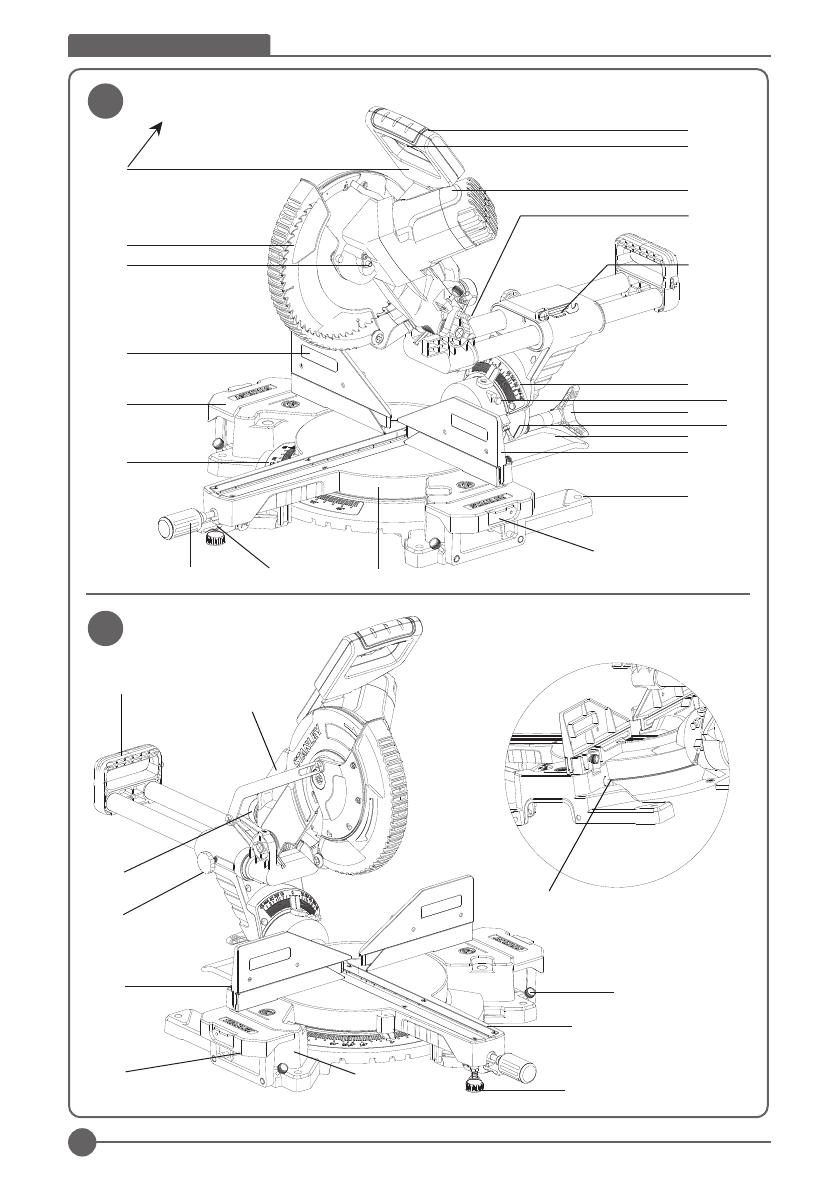

a

l

w

ggg

q

mm

cc

aa

p

c

j

ee

dt

e

f

v

u

b

x

o

n

aaa

m

ddd

r

g

k

s

i

ii

bbb

ccc

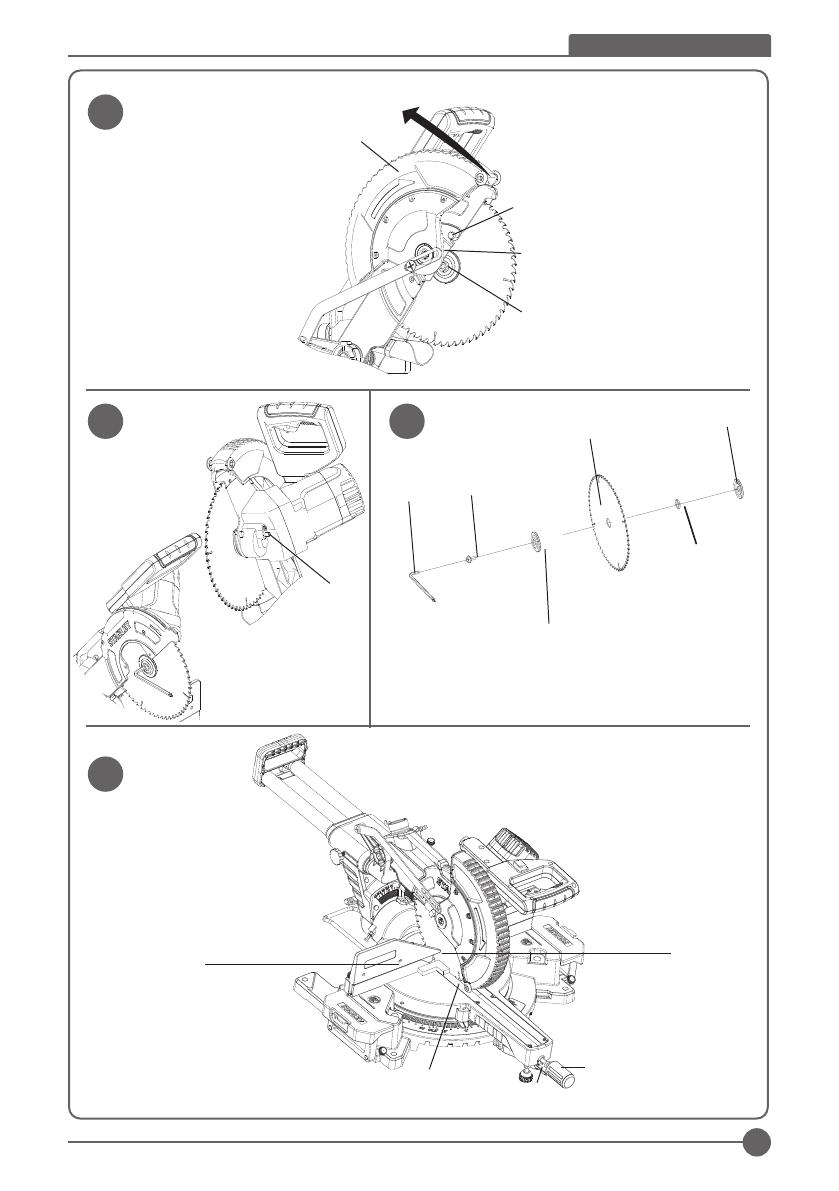

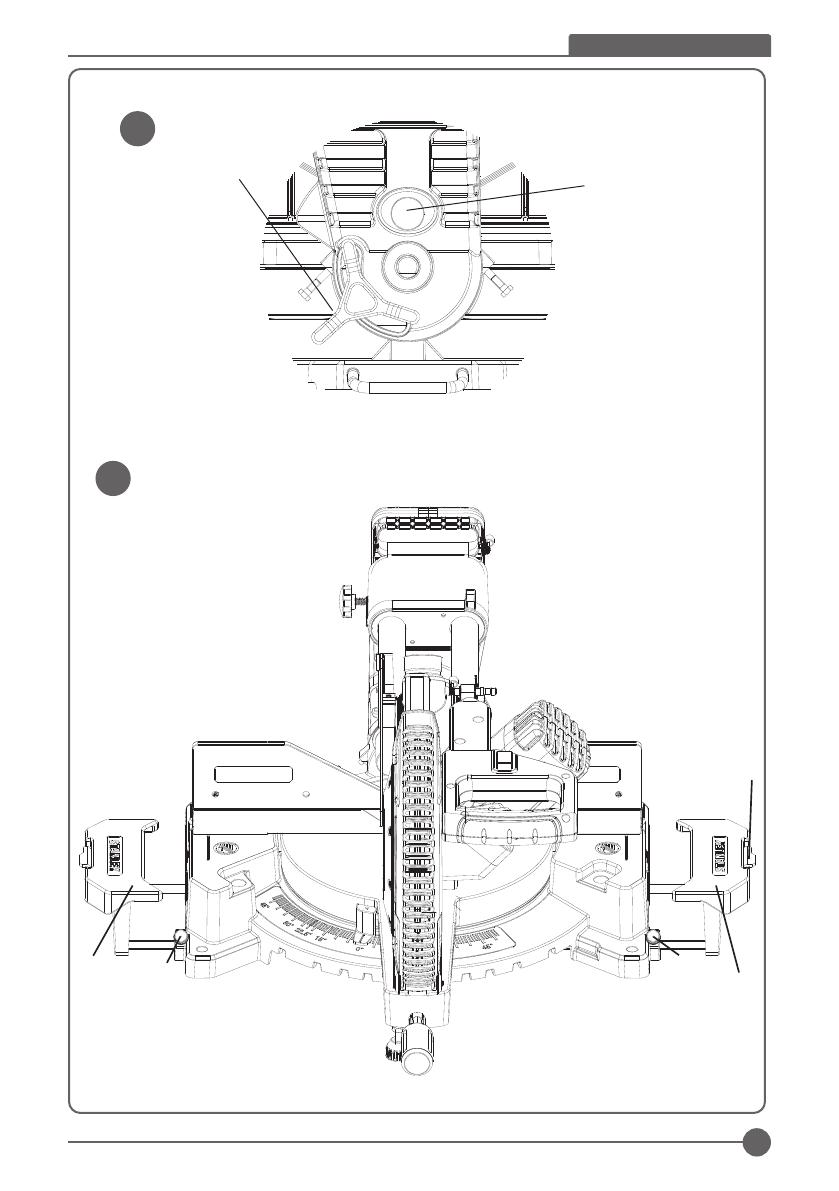

1

2

3

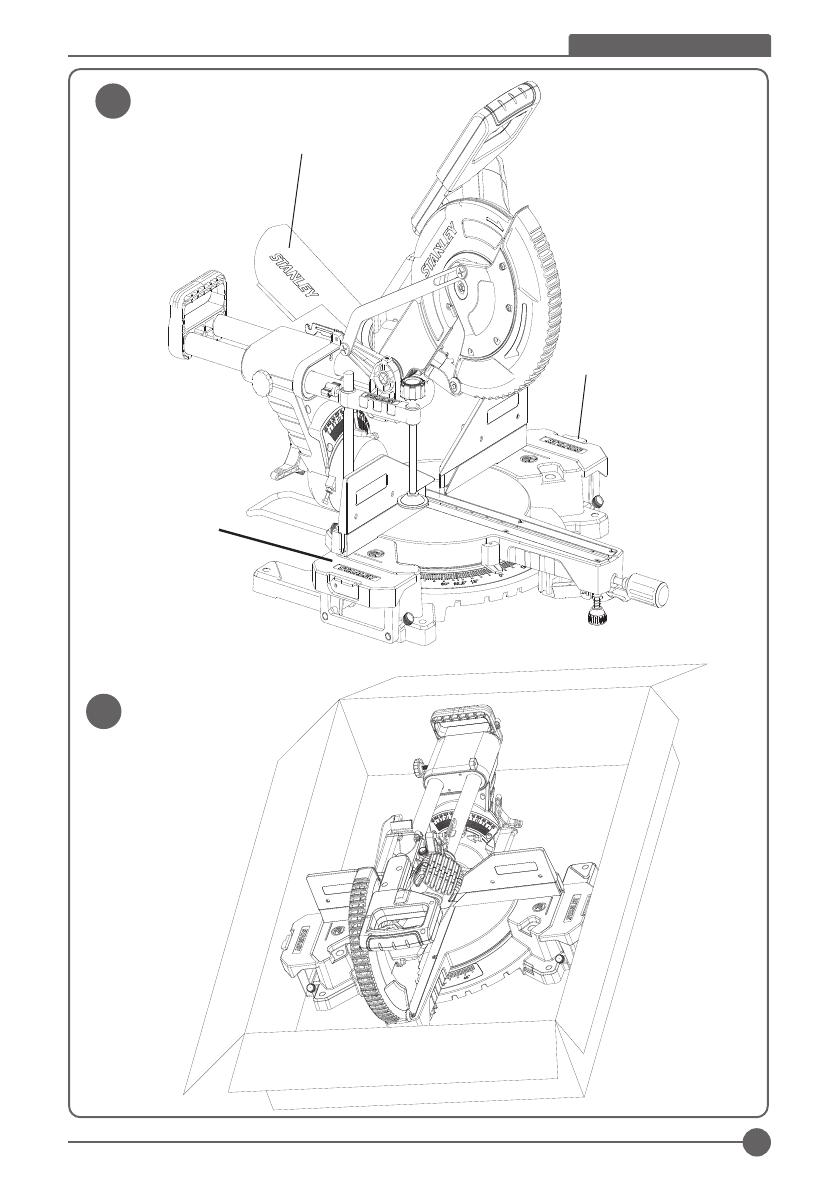

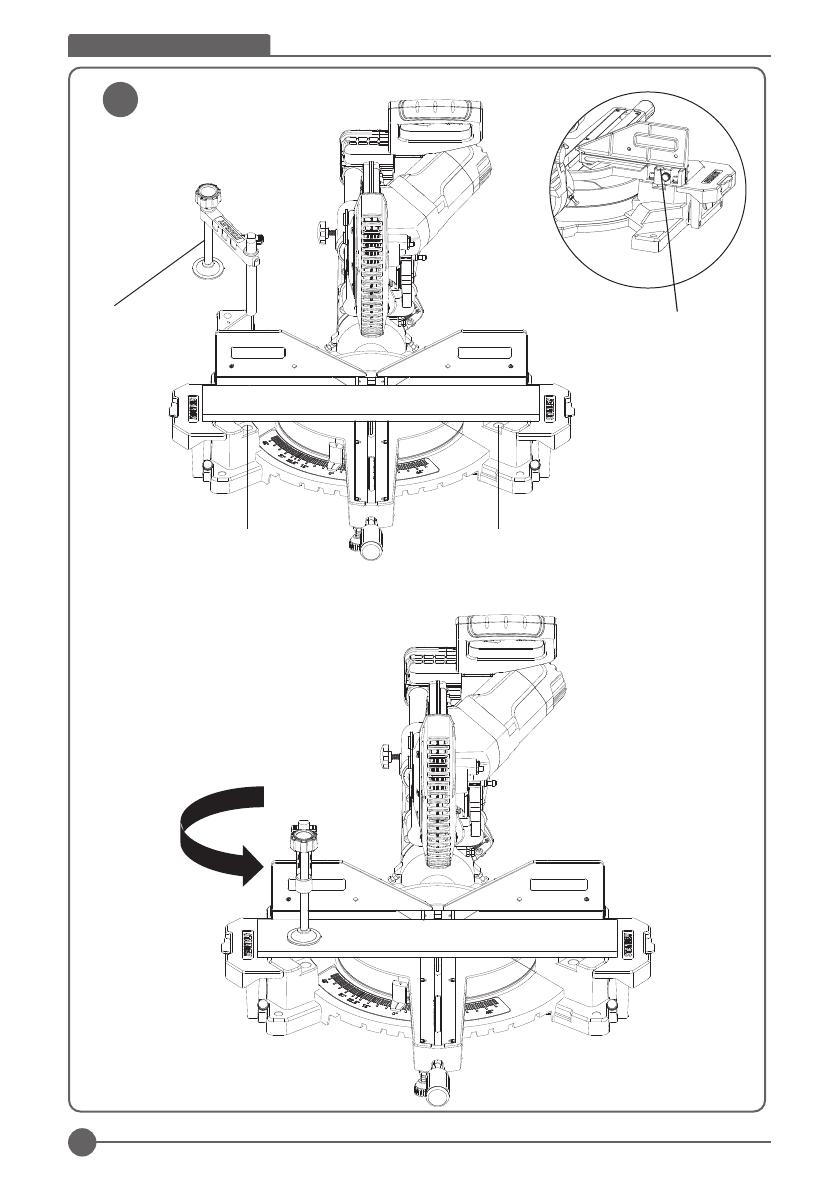

ENGLISH (Original Instructions)

ii

ff

ee

3

4

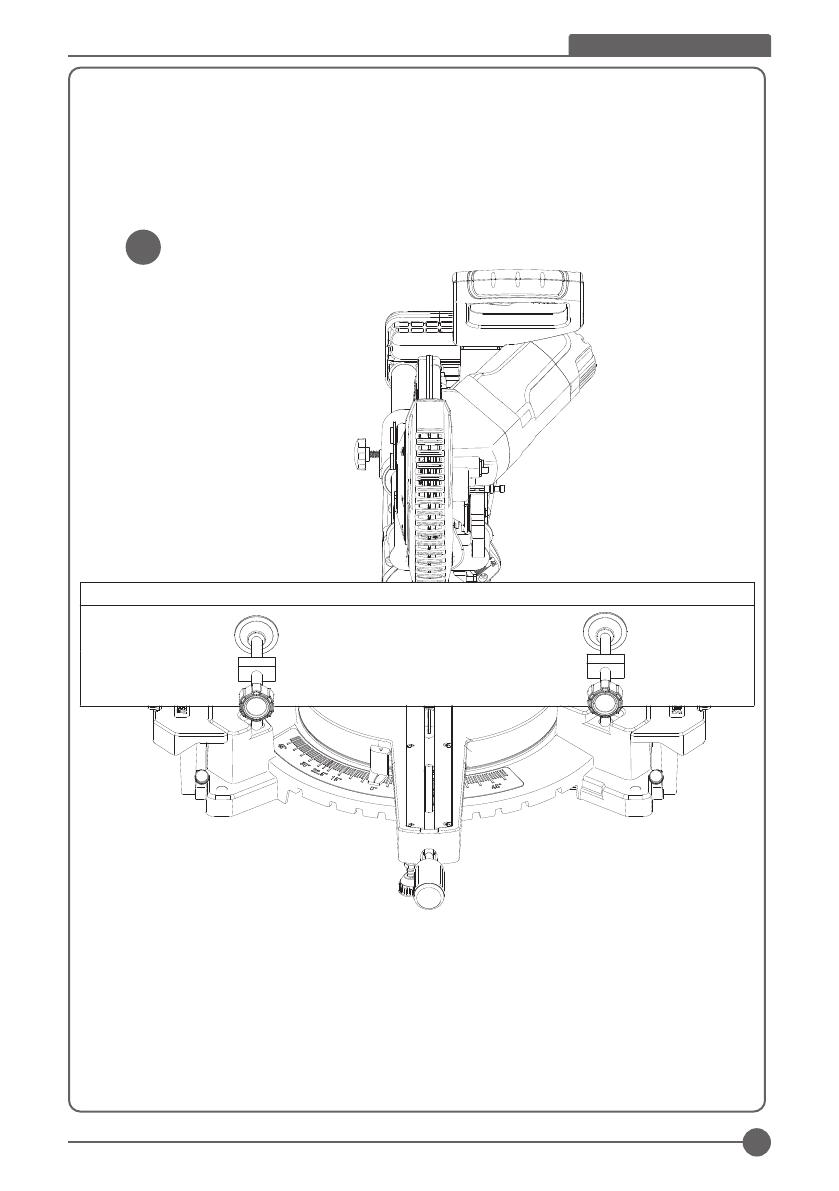

ENGLISH (Original Instructions)

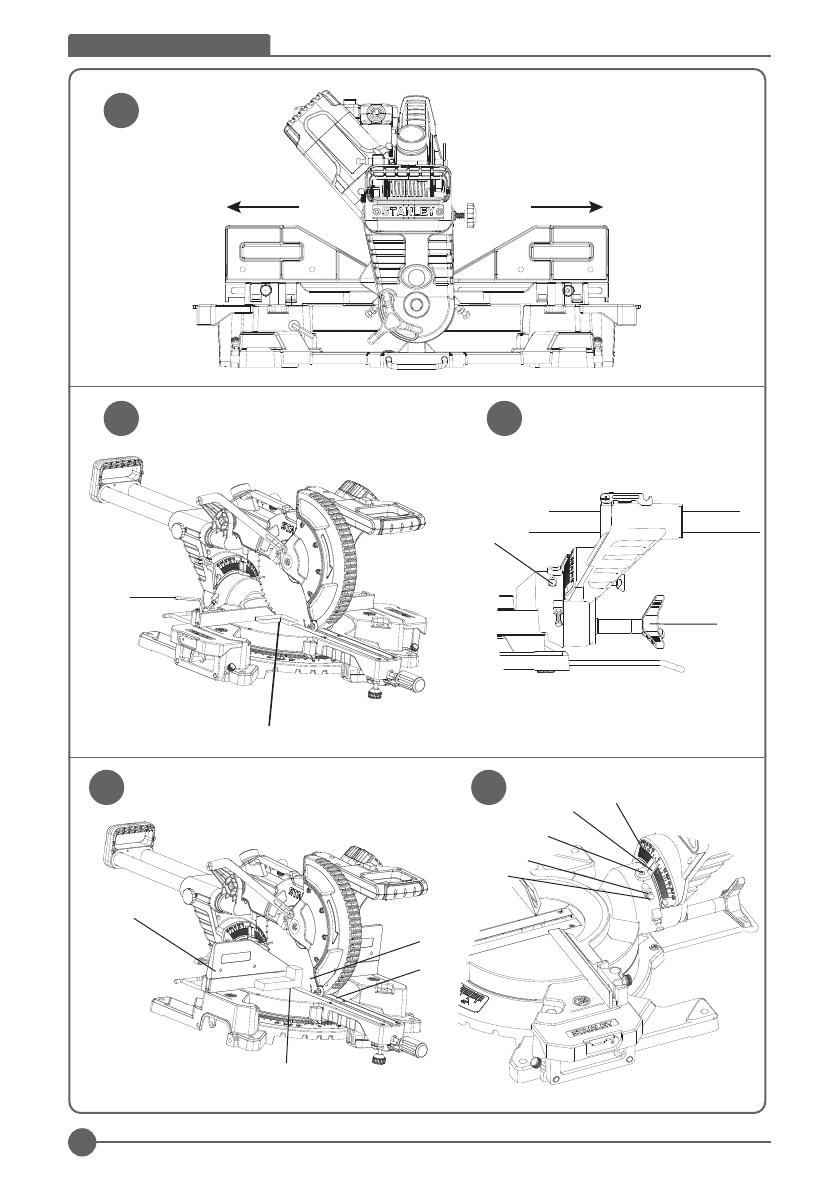

4

i

mm

o

j

7

5

6

5

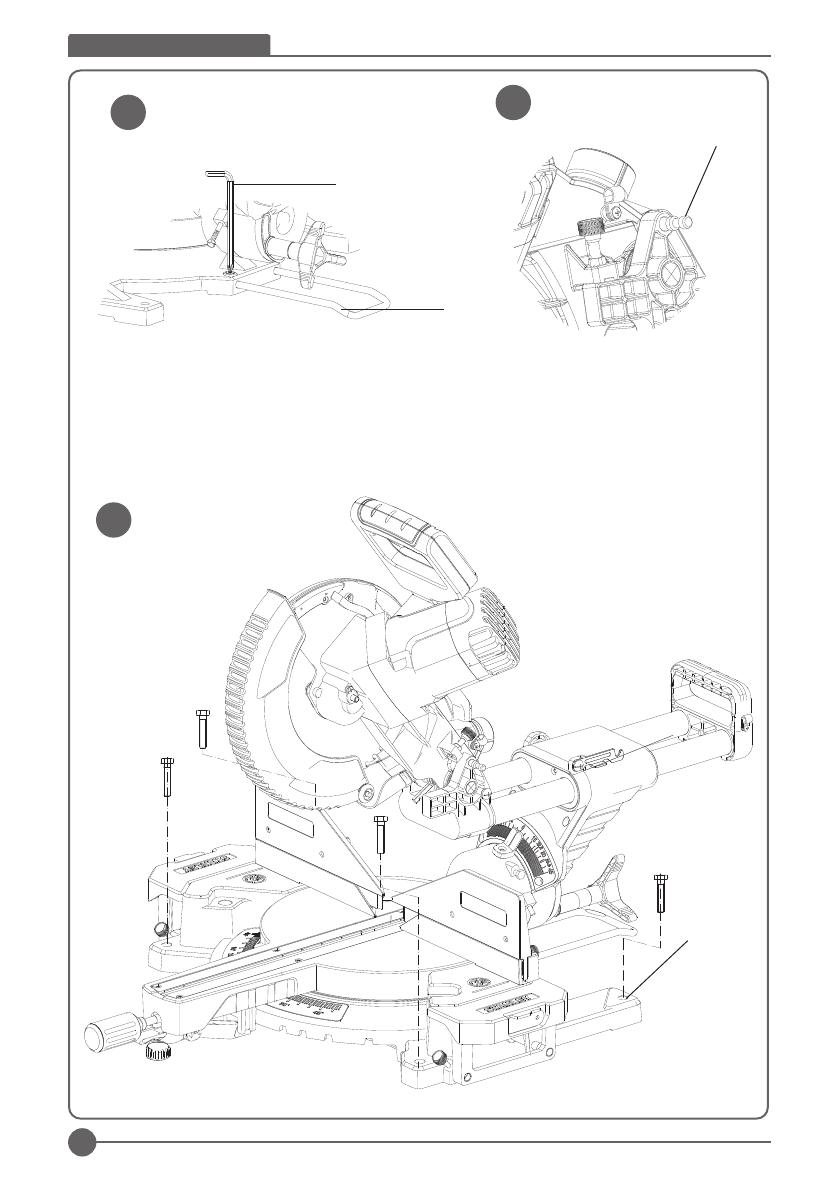

ENGLISH (Original Instructions)

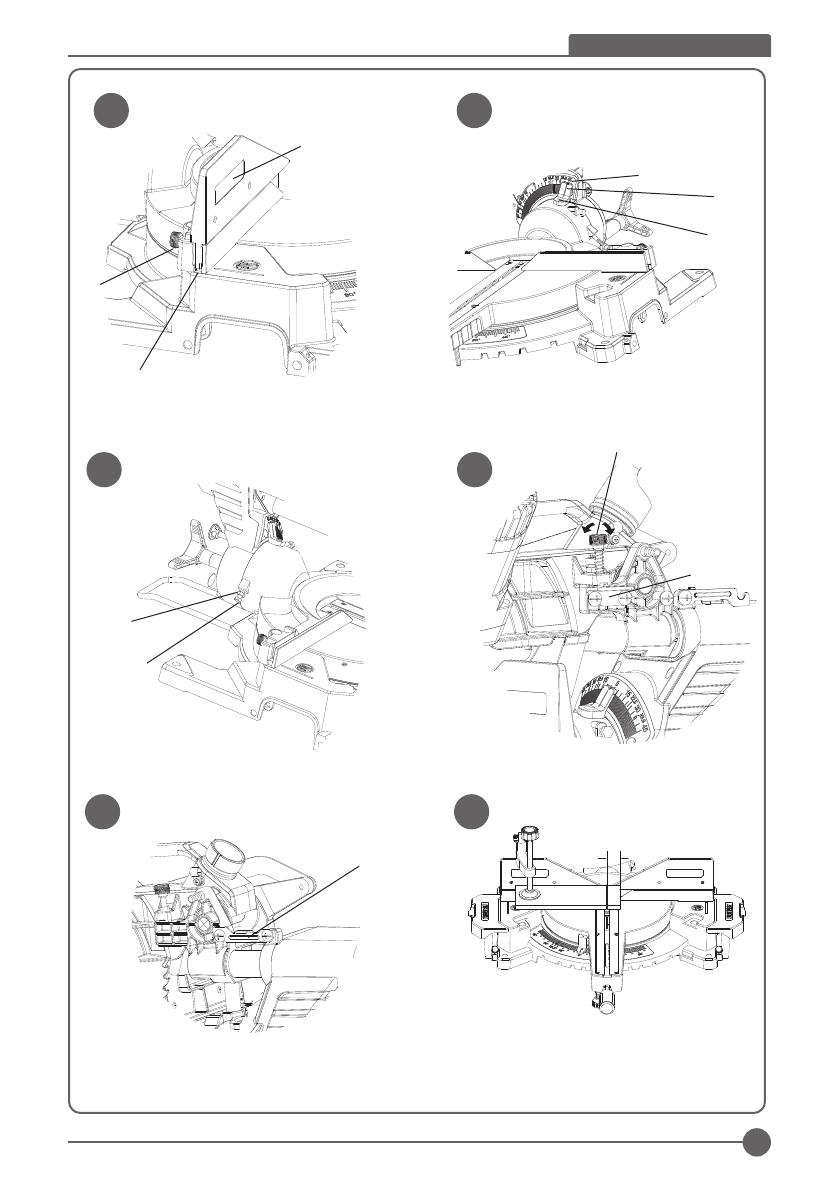

i

nn

pp

v

s

t

e

oo

oo

rr

uu

x

ll

nn

kk

bb

8

9 10

11

ENGLISH (Original Instructions)

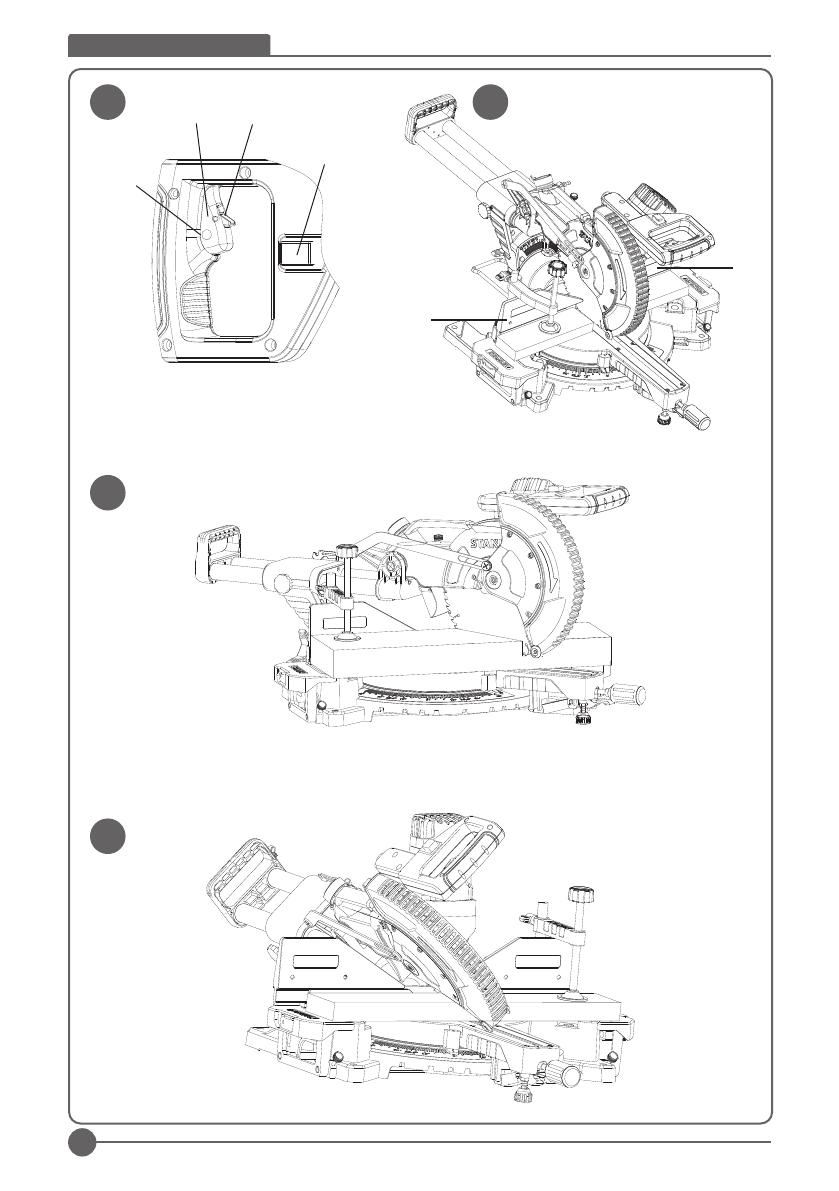

6

tt

i

tt

oo

s

v

cc

p

xx

q

yy

ww

cc

12

13 14

15 16

7

ENGLISH (Original Instructions)

v

k

zz

aa

ww

>30mm

ggg

q

yy

xx

17

19

18

20

21 22

ss

hhh

ENGLISH (Original Instructions)

8

dd

bb

c

v

y

I

23

25

26

24

9

ENGLISH (Original Instructions)

ee

ii

ii

h

h

p

fff

27

28

ENGLISH (Original Instructions)

10

gg

29

11

ENGLISH (Original Instructions)

30

ENGLISH (Original Instructions)

12

31

32

34

35

33

13

ENGLISH (Original Instructions)

36

37

ENGLISH (Original Instructions)

14

INTENDED USE

Your STANLEY Mitre Saw SM18 has been designed for

cutting wood and aluminum, wood products, aluminum

products and plastics. It performs the sawing operations of

cross-cutting, bevelling and mitring easily, accurately and

safely. This tool is intended for professional use.

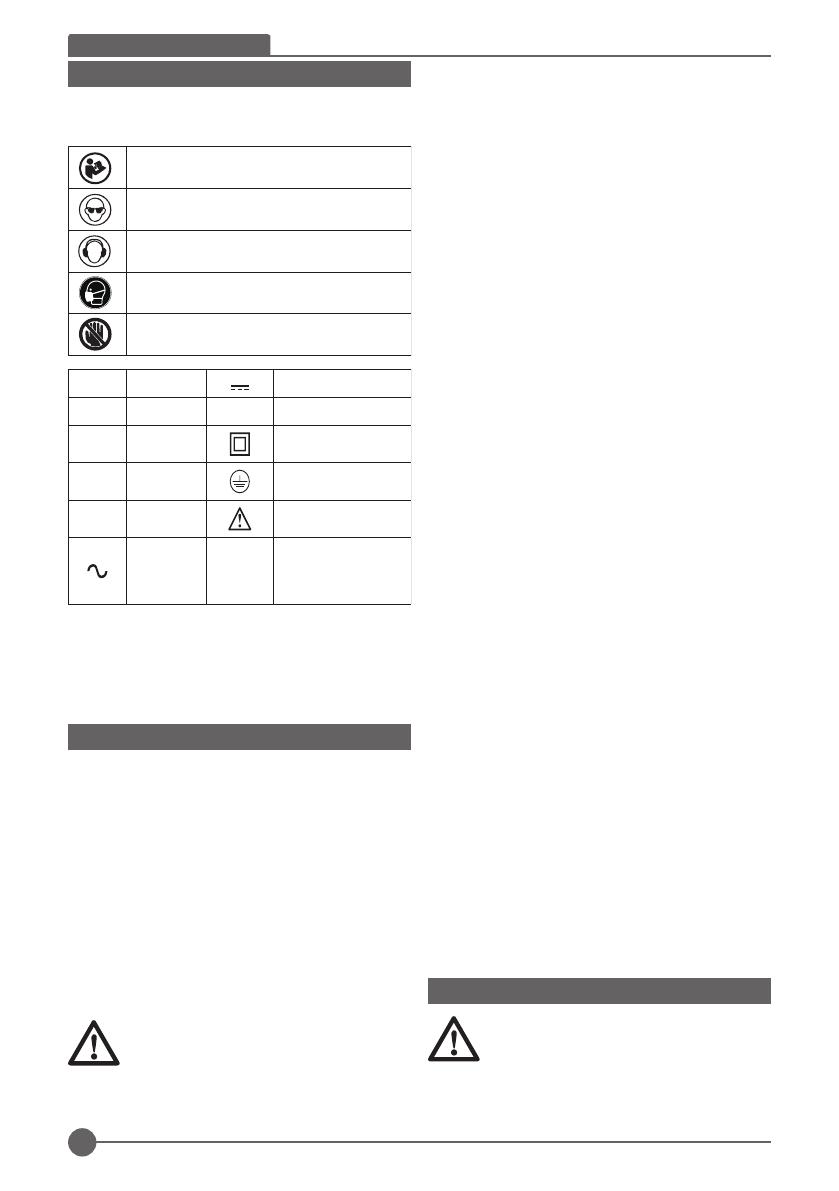

SAFETY INSTRUCTIONS

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to

these symbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

Denotes risk of electric shock.

Denotes risk of fire.

Warning: To reduce the risk of injury, read the

instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings, instruc—

tions, illustrations and specifications pro—

vided with this power tool. Failure to follow all

instructions listed below may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future

reference

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery operated

(cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

2. Electrical Safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal Safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may

result in serious personal injury.

b. Use personal protective equipment. Always wear

eye protection. Protective equipment such as a dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

c. Prevent unintentional starting. Ensure the switch

is in the off position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch

on invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

h. Do not let familiarity gained from frequent use of

tools allow you to become complacent and ignore

tool safety principles. A careless action can cause

severe injury within a fraction of a second.

15

ENGLISH (Original Instructions)

4. Power Tool Use And Care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

c. Disconnect the plug from the power source and/

or remove the battery pack, if detachable from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

e. Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

h. Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

5. Service

a. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power tool

is maintained.

SAFETY INSTRUCTIONS FOR MITRE SAWS

♦ Mitre saws are intended to cut wood or wood—like

products, they cannot be used with abrasive cut-

off wheels for cutting ferrous material such as

bars, rods, studs, etc. Abrasive dust causes moving

parts such as the lower guard to jam. Sparks from

abrasive cutting will burn the lower guard, the kerf

insert and other plastic parts.

♦ Use clamps to support the workpiece

wheneverpossible. If supporting the workpiece

by hand, you must always keep your hand at least

100 mm from either side of the saw blade. Do not

use this saw to cut pieces that are too small to be

securely clamped or held by hand. If your hand is

placed too close to the saw blade,there is an increased

risk of injury from blade contact.

♦ The workpiece must be stationary and clamped or

held against both the fence and the table. Do not

feed the workpiece into the blade or cut “freehand”

in any way. Unrestrained or moving workpieces could

be thrown at high speeds,causing injury.

♦ Push the saw through the workpiece. Do not

pull the saw through the workpiece. To make a

cut, raise the saw head and pull it out over the

workpiece without cutting, start the motor, press

the saw head down and push the saw through

the workpiece. Cutting on the pull stroke is likely to

cause the saw blade to climb on top of the workpiece

and violently throw the blade assembly towards the

operator.

♦ Never cross your hand over the intended line of

cutting either in front or behind the saw blade.

Supporting the workpiece “cross handed” i.e. holding

the workpiece to the right of the saw blade with your

left hand or vice versa is very dangerous.

♦ Do not reach behind the fence with either hand

closer than 100 mm from either side of the saw

blade, to remove wood scraps, or for any other

reason while the blade is spinning. The proximity

of the spinning saw blade to your hand may not be

obvious and you may be seriously injured.

♦ Inspect your workpiece before cutting. If the

workpiece is bowed or warped, clamp it with the

outside bowed face toward the fence. Always

make certain that there is no gap between the

workpiece, fence and table along the line of the

cut. Bent or warped workpieces can twist or shift and

may cause binding on the spinning saw blade while

cutting. There should be no nails or foreign objects in

the workpiece.

♦ Do not use the saw until the table is clear of all

tools, wood scraps, etc., except for the workpiece.

Small debris or loose pieces of wood or other objects

that contact the revolving blade can be thrown with

high speed.

♦ Cut only one workpiece at a time. Stacked multiple

workpieces cannot be adequately clamped or braced

and may bind on the blade or shift during cutting.

♦ Ensure the mitre saw is mounted or placed on

a level, firm work surface before use.A level and

firm work surface reduces the risk of the mitre saw

becoming unstable.

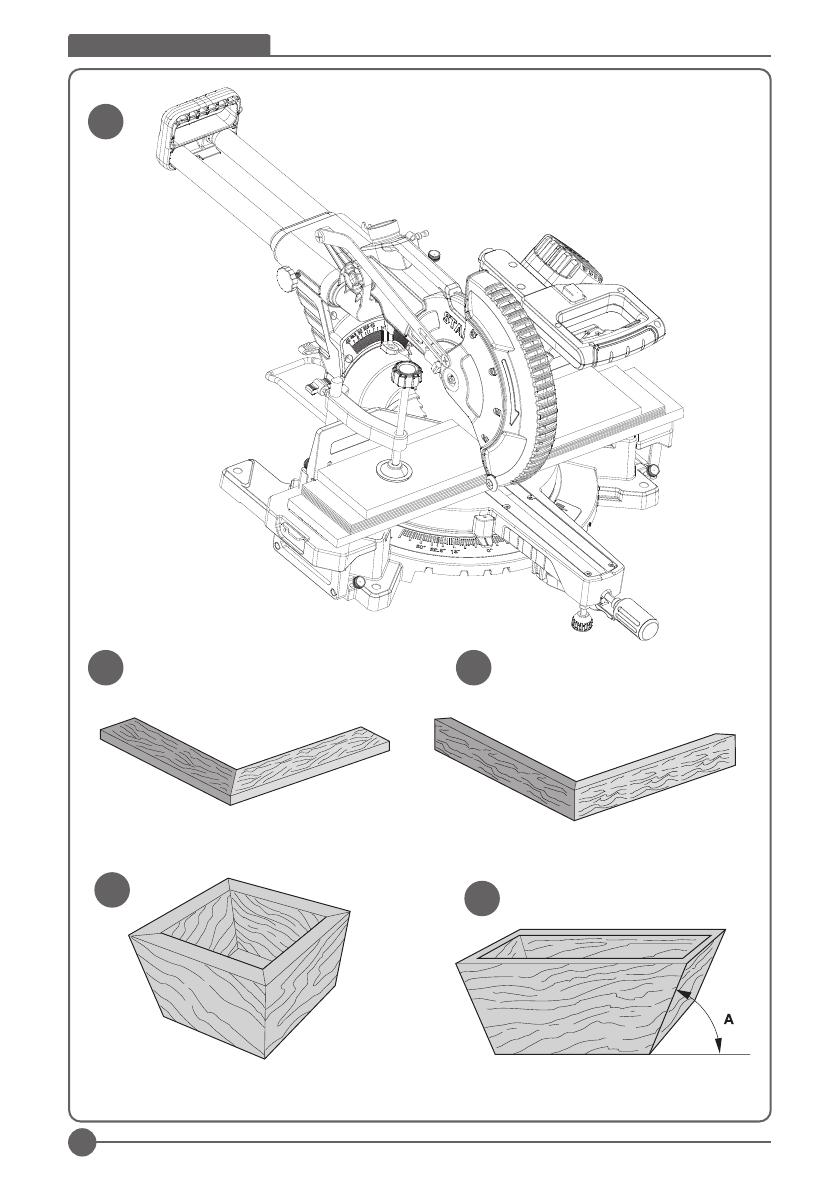

♦ Plan your work. Every time you change the bevel

or mitre angle setting, make sure the adjustable

fence is set correctly to support the workpiece

and will not interfere with the blade or the

guarding system. Without turning the tool “ON” and

with no workpiece on the table, move the saw blade

through a complete simulated cut to assure there will

be no interference or danger of cutting the fence.

♦ Provide adequate support such as table

extensions, saw horses, etc. for a workpiece that

is wider or longer than the table top. Workpieces

longer or wider than the mitre saw table can tip if not

securely supported. If the cut-off piece or workpiece

ENGLISH (Original Instructions)

16

tips, it can lift the lower guard or be thrown by the

spinning blade.

♦ Do not use another person as a substitute for a

table extension or as additional support. Unstable

support for the workpiece can cause the blade to bind

or the workpiece to shift during the cutting operation

pulling you and the helper into the spinning blade.

♦ Thecut-offpiecemustnotbejammedorpressed

byanymeansagainstthe spinning saw blade. If

confined, i.e. using length stops, the cut-off piece could

get wedged against the blade and thrown violentiy.

♦ Always use aclamp or a fixture designed to

properly support round material such as rods or

tubing. Rods have a tendency to roll while being cut,

causing the blade to “bite” and pull the work with your

hand into the blade.

♦ Let the blade reach full speed before contacting

the workpiece. This will reduce the risk of the

workpiece being thrown.

♦ If the workpiece or blade becomes jammed, turn

the mitre saw off.Wait for all moving parts to stop

and disconnect the plug from the power source

and/ or remove the battery pack. Then work to

free the jammed material. Continued sawing with

a jammed workpiece could cause loss of control or

damage to the mitre saw.

♦ After finishing the cut, release the switch, hold

the saw head down and wait for the blade to stop

before removing the cut-off piece. Reaching with

your hand near the coasting blade is dangerous.

♦ Hold the handle firmly when making an incomplete

cut or when releasing the switch before the saw

head is completely in the down position. The

braking action of the saw may cause the saw head to

be suddenly pulled downward, causing a risk of injury.

ADDITIONAL SAFETY RULES FOR MITRE

SAWS

♦ The machine is provided with a special configured

power supply cord which can only be replaced by the

manufacturer or its authorised service agent.

♦ Do not use the saw to cut other materials than those

recommended by the manufacturer.

♦ Cutting plastics, sap coated wood, and other materials

may cause melted material to accumulate on the blade

tips and the body of the saw blade, increasing the risk

of blade overheating and binding while cutting.

♦ Do not operate the machine without guards in posi—

tion, or if guards do not function or are not maintained

properly.

♦ Ensure that the arm is securely fixed when performing

bevel cuts.

♦ Keep the floor area around the machine level,

well-maintained and free of loose materials, e.g., chips

and cut-offs.

♦ Use correctly sharpened saw blades. Observe the

maximum speed mark on the saw blade.

♦ Make sure all locking knobs and clamp handles are

tight before starting any operation.

♦ Never place either hand in the blade area when the

saw is connected to the electrical power source.

♦ Never attempt to stop a machine in motion rapidly by

jamming a tool or other means against the blade; seri—

ous accidents can occur.

♦ Before using any accessory consult the instruction

manual. The improper use of an accessory can cause

damage.

♦ Use a holder or wear gloves when handling a saw

blade.

♦ Ensure that the saw blade is mounted correctly before

use.

♦ Make sure that the blade rotates in the correct

direction.

♦ Take care when slotting.

♦ Do not use blades of larger or smaller diameter than

recommended. For the proper blade rating refer to the

technical data. Use only the blades specified in this

manual, complying with EN 847-1.

♦ Consider applying specially designed noise-reduction

blades.

♦ Do not use HSS blades.

♦ Do not use cracked or damaged saw blades.

♦ Do not use any abrasive or diamond discs.

♦ Never use your saw without the kerf plate.

♦ Raise the blade from the kerf in the workpiece prior to

releasing the switch.

♦ Do not wedge anything against the fan to hold the

motor shaft.

♦ The blade guard on your saw will automatically raise

when the arm is brought down; it will lower over the

blade when head lock up release lever (cc) is pushed.

♦ Never raise the blade guard manually unless the saw

is switched off. The guard can be raised by hand when

installing or removing saw blades or for inspection of

the saw.

♦ Check periodically that the motor air slots are clean

and free of chips.

♦ Replace the kerf plate when worn. Refer to service

parts list included.

♦ Disconnect the machine from the mains before

carrying out any maintenance work or when changing

the blade.

♦ Never perform any cleaning or maintenance work

when the machine is still running and the head is not

in the rest position.

♦ When possible, always mount the machine to a bench.

♦ The front section of the guard is louvered for visibility

while cutting. Although the louvers dramatically

reduce flying debris, they are openings in the guard

and safety glasses should be worn at all times when

viewing through the louvers.

♦ Connect the saw to a dust collection device when

sawing wood. Always consider factors which influence

exposure of dust such as:

– type of material to be machined (chip board

produces more dust than wood);

17

ENGLISH (Original Instructions)

– sharpness of the saw blade;

– correct adjustment of the saw blade,

– dust extractor with air velocity not less than 20 m/s.

Ensure that the local extraction as well as hoods, baffles

and chutes are properly adjusted.

♦ Please be aware of the following factors influencing

exposure to noise:

– use saw blades designed to reduce the emitted

noise;

– use only well sharpened saw blades;

♦ Machine maintenance shall be conducted periodically;

♦ Machine faults, including guards or saw blade, shall be

reported as soon as they are discovered;

♦ Provide adequate general or localized lighting;

♦ Ensure the operator is adequately trained in the use,

adjustment and operation of the machine;

♦ Ensure that any spacers and spindle rings are suitable

for the purpose as stated in this manual.

♦ Refrain from removing any cut-offs or other parts of

the workpiece from the cutting area while the machine

is running and the saw head is not in the rest position

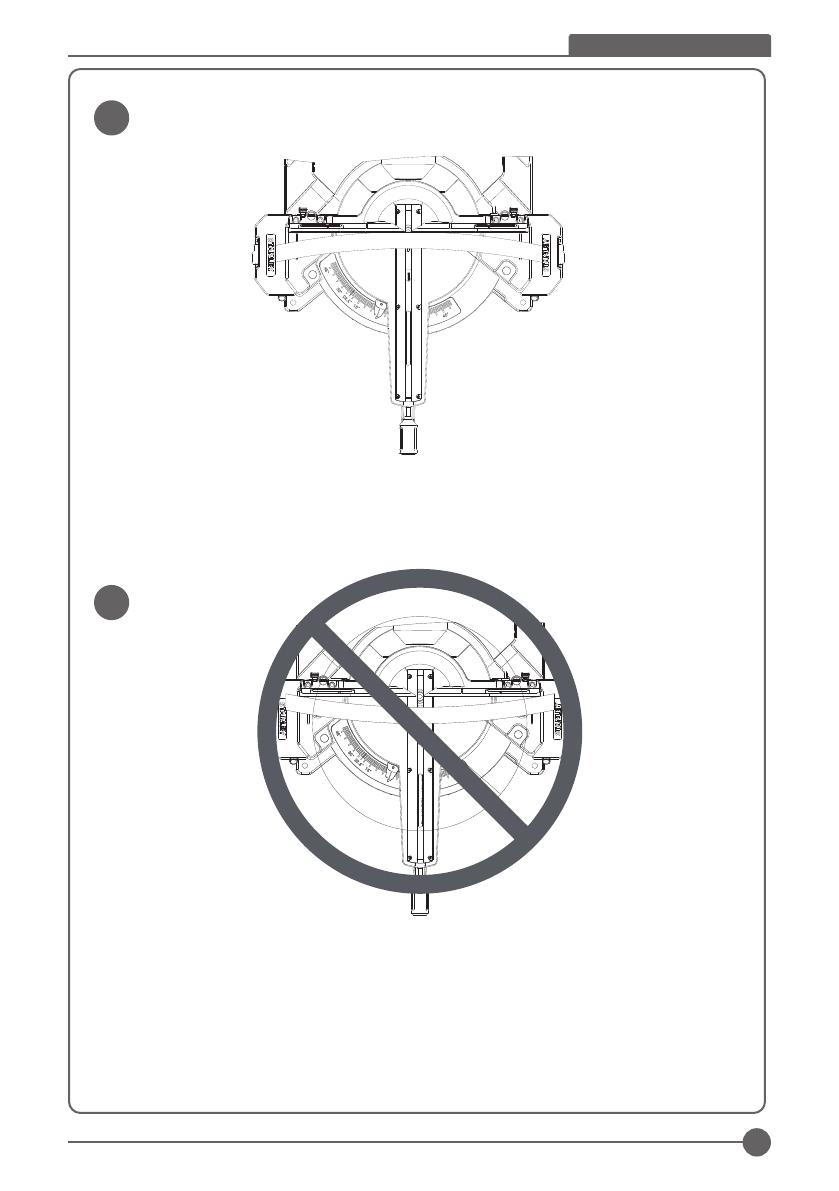

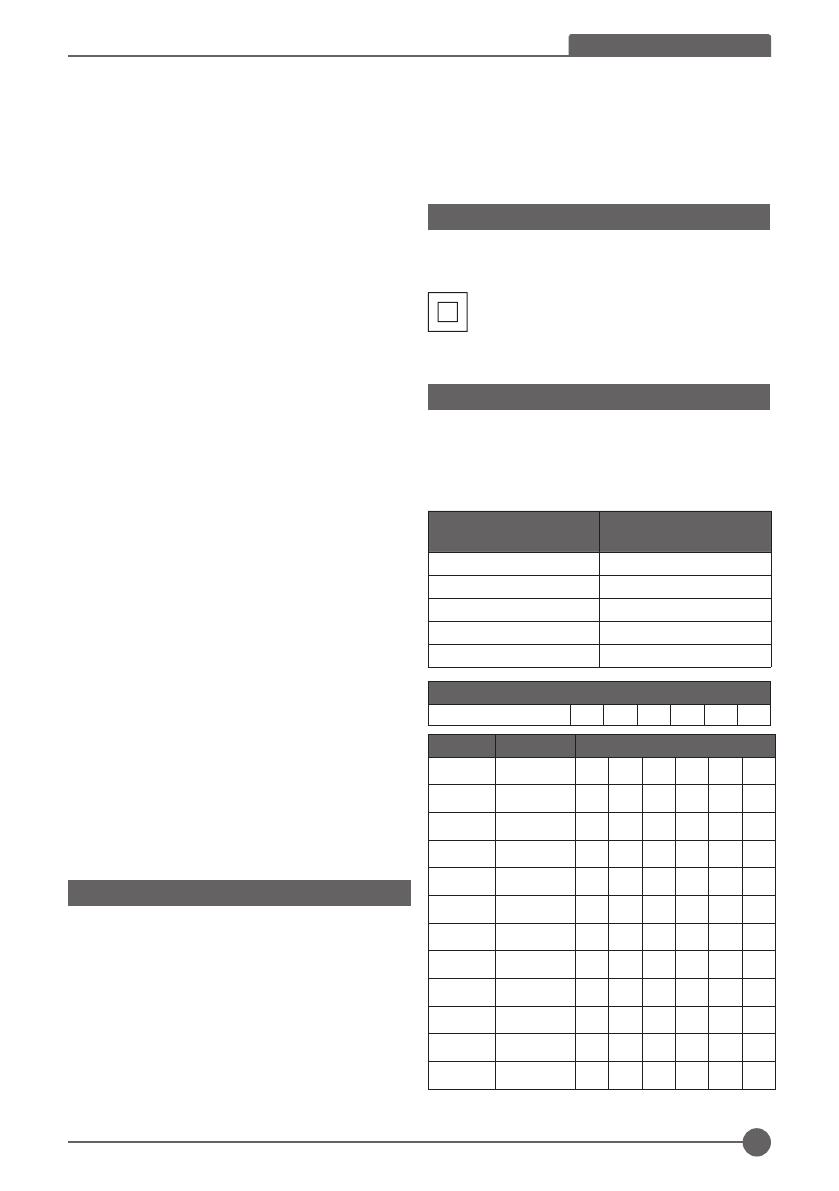

♦ Never cut workpieces shorter than 30 mm(Figure 34).

♦ Without additional support the machine is designed to

accept the maximum workpiece size of:

– Height 75 mm by width 140 mm by length 460 mm

– Longer workpieces need to be supported by suit—

able additional table(work support). Always clamp

the workpiece safely.

♦ In case of an accident or machine failure, immediately