- 17741

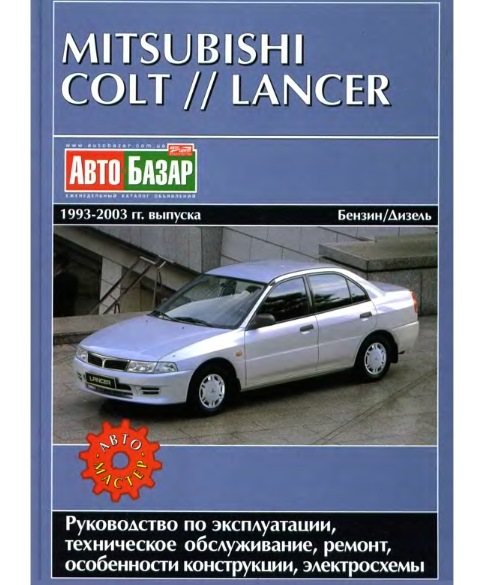

Мануал по ремонту двигателей Митсубиси 4 модификации 4G13, 4G92, 4G93, 4D68 с описанием и подробными картинками — замена тнвд gdi, датчиков, ГРМ, ГБЦ, Блок, коленвал, распредвал и тд

Двигатель 4G93 технические характеристики

Объем двигателя, куб.см 1834

Максимальная мощность, л.с. 110 — 150

Расход топлива, л/100 км 3.9 — 10

Тип двигателя 4-цилиндровый, 16-клапанный, DOHC

Доп. информация о двигателе DOHC

Диаметр цилиндра, мм 78 — 81

Количество клапанов на цилиндр 4

Автор Mitsubishi

формат PDF

Ремонт двигателя 4g93

Добавлять комментарии могут только зарегистрированные пользователи.

[

Регистрация

|

Вход

]

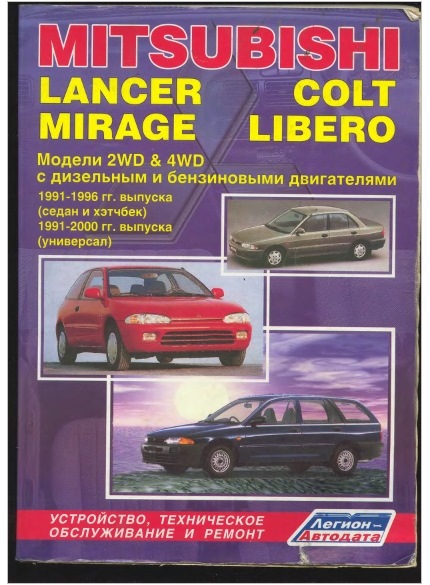

Всем привет! Решил поделиться книгами по ремонту и эксплуатации автомобиля Митсубиси Лансер, так как они разбросаны по просторам интернета и не везде даются для бесплатного скачивания.Нашел 3 книги и надеюсь кому-то пригодятся.

1

2

3

1.Необходимо скачать по ссылке: dfiles.ru/files/xha5n4hio

.

2.Разархивировать папку ;

3.Установить для просмотра DjVU editor.

- Manuals

- Brands

- Mitsubishi Manuals

- Engine

- 4G92-DOHC-MIVEC

Manuals and User Guides for Mitsubishi 4G92-DOHC-MIVEC. We have 2 Mitsubishi 4G92-DOHC-MIVEC manuals available for free PDF download: User Manual, Manual

Mitsubishi 4G92-DOHC-MIVEC User Manual (172 pages)

4G9 Series

Brand: Mitsubishi

|

Category: Engine

|

Size: 4.59 MB

Table of Contents

-

Table of Contents

1

-

General Information

3

-

Technical Data

3

-

Service Specifications

6

-

-

1-1

6

-

Rework Dimensions

9

-

Torque Specifications

10

-

New Tightening Method — by Use of Bolts to be Tightened in Plastic Area

16

-

Sealant

16

-

Form-In-Place Gasket

17

-

Disassembly

17

-

Surface Preparation

17

-

Form-In-Place Gasket Application

17

-

-

-

2 Special Tools

18

-

2-1

18

-

4G9 Engine (E

18

-

-

-

3 Alternator and Ignition System

21

-

3-1

21

-

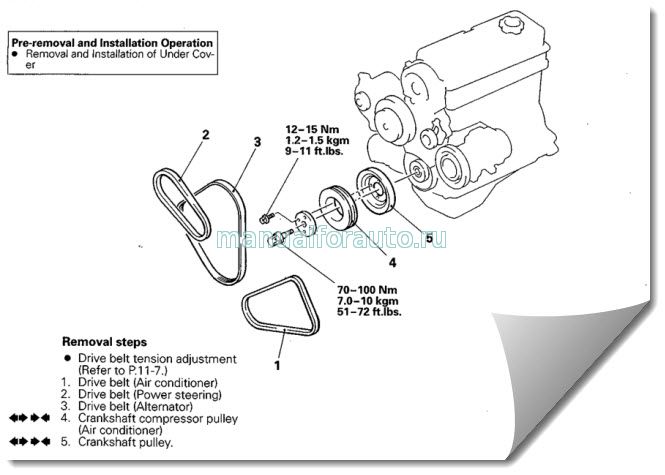

Removal and Installation <SOHC> (Engines with Distributor)

21

-

Removal and Installation (SOHC for Other than Pajero) (Engines Without Distributor)

22

-

Removal and Installation <SOHC for Pajero Io> (Engines Without Distributor)

23

-

Removal and Installation (DOHC)

25

-

Removal and Installation (DOHC-MIVEC)

26

-

Removal and Installation (DOHC–GDI for Carisma, Space Star, Space Runner, Galant)

27

-

Alternator Brace (M8)

28

-

Cam Position Sensing Cylinder

28

-

Cam Position Sensor Support

28

-

Crankshaft Bolt

28

-

Ignition Coil

28

-

Oil Level Gauge

28

-

Power Steering Pump Pulley

28

-

Removal and Installation (DOHC-GDI for Pajero Io)

28

-

Spark Plug

28

-

«BA Front Flange/Crankshaft Pulley/Crankshaft Bolt Installation

29

-

Installation Service Points «AA Cam Position Sensor Support

29

-

Removal Service Point AA» Crankshaft Bolt Removal

29

-

-

4-1

30

-

Camshaft Sprocket Bolt

30

-

Engine Support Bracket, Right

30

-

Timing Belt Rear Cover

30

-

Timing Belt Removal and Installation (SOHC for Carisma (up for 1999 Model)

30

-

Timing Belt Removal and Installation (SOHC for Carisma (from 2000 Model), Lancer (from 2001 Model for Europe), Space Star)

31

-

-

Accessory Mount

33

-

Timing Belt Cover

33

-

Timing Belt Removal and Installation (SOHC for Pajero Io)

33

-

Timing Belt Removal and Installation (DOHC)

34

-

Timing Belt Removal and Installation (DOHC-MIVEC)

35

-

Timing Belt Removal and Installation (DOHC-GDI for Carisma, Space Star, Space Runner)

36

-

Timing Belt Removal and Installation (DOHC-GDI for Galant)

37

-

Timing Belt Removal and Installation (DOHC-GDI for Pajero Io)

38

-

«AA Camshaft Sprocket Bolt Installation

40

-

AA» Timing Belt Removal

40

-

AB» Camshaft Sprocket Bolt Removal

40

-

«BA Timing Belt Tensioner Installation

41

-

«CA Tensioner Spring Installation

41

-

«DA Timing Belt Installation

41

-

«EA Auto-Tensioner Installation

42

-

«FA Timing Belt Installation

43

-

«GA Crankshaft Sensing Blade/Crankshaft Spacer/Crankshaft Sprocket Installation

45

-

Timing Belt Inspection

45

-

Tensioner Pulley, Idler Pulley Inspection

46

-

-

-

5 Fuel and Emission Control System

47

-

5-1

47

-

SOHC Carburetor Removal and Installation

47

-

Fuel and Emission Control System Removal and Installation (SOHC-MPI for Other Tnan Pajero Io)

48

-

Fuel and Emission Control System Removal and Installation (SOHC-MPI for Pajero Io)

49

-

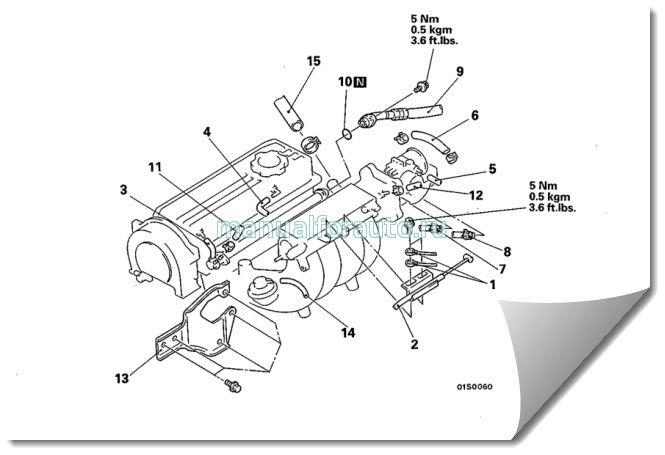

Fuel and Emission Control System Removal and Installation (DOHC)

50

-

«AA Injectors Installation

51

-

«BA Fuel Pressure Regulator Installation

51

-

«CA Gasket Installation

51

-

-

5A. THROTTLE BODY and EGR SYSTEM (GDI)

53

-

Throttle Body and EGR System Removal and Installation (up to 2000 Model for Carisma, 1999 Model for Space Star, Spacer Runner)

53

-

Throttle Body and EGR System Removal and Installation (from 2001 Model for Carisma, Space Star and Galant)

54

-

Throttle Body and EGR System Removal and Installation (for Pajero Io — 4G93)

55

-

Throttle Body and EGR System Removal and Installation (for Pajero Io — 4G94)

56

-

«BA Intake Manifold Stay Installation

57

-

-

-

6 Intake and Exhaust Manifold

58

-

Installation Service Points: «AA Throttle Body Gasket

57

-

6-1

58

-

Intake and Exhaust Manifold Removal and Installation (SOHC-Carburetor)

58

-

Intake and Exhaust Manifold Removal and Installation (SOHC-MPI-Front Wheel Drive (4G92 and 4G93–Except from 2001 Model for Europe))

59

-

Intake and Exhaust Manifold Removal and Installation (SOHC-MPI-Front Wheel Drive (4G92 and 4G93– from 2001 Model for Europe))

60

-

Intake and Exhaust Manifold Removal and Installation (SOHC-MPI-Front Wheel Drive (4G94)

61

-

Intake and Exhaust Manifold Removal and Installation (SOHC-MPI-Rear Wheel Drive (4G93 — Except from 2002 Model for Europe)

62

-

Intake and Exhaust Manifold Removal and Installation (SOHC-MPI-Rear Wheel Drive (4G93 — from 2002 Model for Europe)

63

-

Intake and Exhaust Manifold Removal and Installation (SOHC-MPI-Rear Wheel Drive (4G94)

64

-

Intake and Exhaust Manifold Removal and Installation (DOHC)

66

-

«AA Exhaust Manifold Bracket Installation

67

-

«BA Intake Manifold Stay — Installation

67

-

Rear Wheel Drive

67

-

-

6A. INTAKE MANIFOLD (GDI)

68

-

Intake Manifold (GDI) Removal and Installatoin (up to 2000 Model for CARISMA, 1999 Model for Space Star, Space Runner)

68

-

Intake Manifold (GDI) Removal and Installation (from 2001 Model for Carisma, Space Star and Galant)

69

-

Intake Manifold (GDI) Removal and Installation (for Space Runner)

71

-

Intake Manifold (GDI) Removal and Installation (for Pajero Io)

72

-

«AA Intake Manifold Stay Installation

73

-

-

6B. EXHAUST MANIFOLD (GDI)

74

-

Exhaust Manifold (GDI) Removal and Installation (for Carisma, Space Star, Space Runner)

74

-

Exhaust Manifold (GDI) Removal and Installation (for Galant)

75

-

Exhaust Manifold (GDI) Removal and Installation (for Pajero Io)

77

-

Exhaust Manifold Bracket Installation

78

-

-

6C. INJECTOR and FUEL PUMP ASSEMBLY (GDI)

79

-

Injector and Fuel Pump Assembly (GDI) (up to 2000 Mode for Carisma, 1999 Model for Space Star, Space Runner)

79

-

Injector and Fuel Pump Assembly (GDI) (from 2001 Model for Carisma, Space Star and Galant)

80

-

Injector and Fuel Pump Assembly (GDI) (for Pajero Io — 4G94)

81

-

Injector and Fuel Pump Assembly (GDI) (for Pajero Io — 4G93)

82

-

Backap Ring/O-Ring/Corrugated Washer Installation

83

-

Delivery Pipe and Injector Assembly Installation

83

-

Fuel High Pressure Regulator Installation

84

-

Fuel Pressure Sensor Installation

84

-

Pump Camshaft Case Installation

84

-

Fuel Pump/Fuel Feed Pipe Installation

85

-

O-Ring/Backup Ring/Fuel Pipe Installation

86

-

O-Ring/Fuel Pump Installation

86

-

JA O-Ring/Fuel Pump Installation

87

-

O-Ring/Backup Ring/Fuel Pressure Sensor Installation

87

-

Intake and Exhaust Manifold <4G94 — GDI for PAJERO Io> Removal and Installation

88

-

Intake Manifold Stay Installation

89

-

To Install the Exhaust Manifold Bracket

89

-

-

7-1

90

-

Water Pump and Water Hose Removal and Installation (SOHC — Front Wheel Drive)

90

-

Water Pump and Water Hose Removal and Installation (SOHC — Rear Wheel Drive)

91

-

Water Pump and Water Hose Removal and Installation (DOHC — Front Wheel Drive)

92

-

Water Pump and Water Hose Removal and Installation (DOHC — Rear Wheel Drive)

93

-

Thermostat Installation

94

-

Water Inlet Pipe (Front Wheel Drive/Water Pipe, Rear Wheel Drive/O-Ring Installation)

94

-

Water Outlet Fitting Installation

94

-

Water Pump Installation

94

-

Engine Coolant Temperature Gauge Unit Installation

95

-

Engine Coolant Temperature Sensor Installation

95

-

Water By-Pass Fitting Installation

95

-

-

8-1

96

-

Rocker Arms and Camshafts Removal and Installation (SOHC (with Adjusting Screw))

96

-

Rocker Arms and Camshafts Removal and Installation (SOHC (with Lash Adjuster))

97

-

Rocker Arms and Camshafts Removal and Installation (DOHC)

99

-

Rocker Arms and Camshafts Removal and Installation (DOHC-GDI)

100

-

Rocker Arms and Camshafts Removal and Installation (DOHC-GDI for Carisma (up to 2000 Model), Space Star (1999 Model), Space Runner)

102

-

Rocker Arms and Camshafts Removal and Installation (DOHC-GDI for Carisma, Space Star and Galant (from 2001 Model))

103

-

Rocker Arms and Camshafts Removal and Installation (DOHC-GDI for Pajero Io — 4G94)

104

-

Rocker Arms and Camshafts Removal and Installation (DOHC-GDI for Pajero Io — 4G93)

105

-

Adjusting Screw Installation

106

-

Lash Adjuster Removal

106

-

Rocker Arm Shaft Installation

106

-

Rocker Arms and Rocker Arm Shaft Installation

106

-

Bearing Cap Installation

107

-

Camshaft Installation

107

-

Lash Adjuster Installation

107

-

Oil Seal Installation

107

-

Beam Camshaft Cap Installation

108

-

O-Ring/Cover Installation

110

-

Sealant Application on Rocker Cover

110

-

Sealant Application on Semi-Circular Parking

110

-

Valve Clearance Adjustment

110

-

Camshaft Inspection

113

-

Lash Adjuster (SOHC)

113

-

Lash Adjuster (DOHC)

116

-

Rocker Cover and Camshafts (MIVEC) Removal and Installation

119

-

Camshaft — Inspection

120

-

Oil Control Valve Inspection

120

-

Camshaft Bearing Cap/Camshaft Holder Installation

121

-

Camshaft Holder Assembly Installation

121

-

Install the Camshaft

121

-

Semi-Circular Packing Installation

121

-

Installation of the Oil Seal

122

-

Oil Control Valve Installation

122

-

Rocker Arm Piston Inspection

123

-

Rocker Cover Installation

123

-

To Adjust the Valve Clearance

123

-

Rocker Arms and Rocker Shaft Caps (MIVEC) Removal and Installation

124

-

Rocker Arm Assembly Installation

125

-

-

9-1

126

-

Cylinder Head and Valves Removal and Installation (SOHC)

126

-

Cylinder Head and Valves Removal and Installation (DOHC)

127

-

Cylinder Head and Valves Removal and Installation (DOHC-MIVEC)

128

-

Cylinder Head and Valves Removal and Installation (DOHC-GDI)

129

-

Cylinder Head Bolt Removal

131

-

Retainer Lock Removal

131

-

Valve Handling Precautions

132

-

Valve Stem Seal Removal

132

-

Valve Stem Seal Installation

133

-

Cylinder Head Bolt Installation

134

-

Retainer Lock Installation

134

-

Valve Spring Installation

134

-

Sealant Application to Oil Pressure Switch

135

-

Cylinder Head Inspection

136

-

Valve Inspection

136

-

Valve Guide Inspection

137

-

Valve Seat Inspection

137

-

Valve Spring Inspection

137

-

Valve Guide Replacement

138

-

Valve Seat Reconditioning Procedure

138

-

Valve Seat Replacement Procedure

138

-

-

10-1

140

-

Front Case and Oil Pump Removal and Installation (SOHC (4G92, 4G93))

140

-

Front Case and Oil Pump Removal and Installation (SOHC (4G94 Except for Pajero Io))

141

-

Front Case and Oil Pump Removal and Installation (SOHC (4G94 for Pajero Io))

142

-

Front Case and Oil Pump Removal and Installation (DOHC (Except GDI for Pajero Io))

143

-

Front Case and Oil Pump Removal and Installation (DOHC-GDI for Pajero Io)

144

-

Inner Rotor/Outer Rotor Installation

145

-

Oil Pan Removal

145

-

Outer Rotor/Inner Rotor Removal

145

-

Sealant Application to Oil Pump Case

145

-

Crankshaft Front Oil Seal Installation

146

-

Oil Pan/Upper Oil Pan/Lower Oil Pan Installation

146

-

Oil Filter Installation

147

-

Oil Pump Inspection

147

-

-

11-1

149

-

Piston and Connecting Rod Removal and Installation

149

-

Connecting Rod Cap Removal

150

-

Piston Pin Removal

150

-

Piston Pin Installation

151

-

Oil Ring Installation

152

-

Piston and Connecting Rod Installation

153

-

Piston Ring #2/Piston Ring #1 Installation

153

-

Connecting Rod Bearing Installation

154

-

Connecting Rod Cap Installation

155

-

Connecting Rod Cap Nut Installation

155

-

Crankshaft Pin Oil Clearance (Plastigauge Method)

156

-

Piston Ring Instpection

156

-

Crankshaft, Cylinder Block, Flywheel and Drive Plate Removal and Installation (Manual Transmission)

157

-

Automatic Transmission Removal and Installation

158

-

Crankshaft, Cylinder Block, Flywheel and Drive Plate Removal and Installation (Pajero Io)

159

-

Crankshaft Bearing Installation

160

-

Oil Jet Installation

160

-

Oil Jet Removal

160

-

Bearing Cap/Bearing Cap Bolt Installation

162

-

Crankshaft Journal Oil Clearance (Plastigauge Method)

163

-

Drive Plate Bolt/Flywheel Bolt Installation

163

-

Sealant Application to Oil Seal Case

163

-

To Install the Oil Seal

163

-

Boring Cylinder Inspection

164

-

Cylinder Block Inspection

164

-

Hydro-Flywheel (DOHC-GDI for Pajero Io) Inspection

165

-

Service Bulletins

167

-

Crankshaft Weight

169

-

-

Advertisement

Mitsubishi 4G92-DOHC-MIVEC Manual (130 pages)

4G9 Series

Brand: Mitsubishi

|

Category: Engine

|

Size: 3.36 MB

Table of Contents

-

Engine

1

-

Table of Contents

1

-

General Information

3

-

1 Specifications

5

-

1-1

5

-

Service Specifications

5

-

Rework Dimensions

8

-

Torque Specifications

8

-

-

-

-

Table of Contents

9

-

New Tightening Method — by Use of Bolts to be Tightened in Plastic Area

13

-

Sealant

13

-

Form-In-Place Gasket

14

-

2 Special Tools

15

-

2-1

15

-

3-1

18

-

4-1

27

-

4G9 Engine (E

35

-

Timing Belt

38

-

Auto-Tensioner Bolt

39

-

-

3 Alternator and Ignition System

18

-

4 Timing Belt

27

-

5 Fuel and Emission Control System

40

-

5-1

40

-

Breather Tube

40

-

Carburetor

40

-

EGR Valve

40

-

Fuel Pump

40

-

Delivery Pipe

41

-

Fuel Pressure Regulator

41

-

Fuel Return Pipe

41

-

Throttle Body

43

-

5A. THROTTLE BODY and EGR SYSTEM (GDI)

46

-

-

Throttle Body Stay

43

-

Air Intake Resonator

46

-

Intake Manifold Stay

46

-

Throttle Body

47

-

-

6 Intake and Exhaust Manifold

49

-

Water Hose Clamp

47

-

Water Pipe

47

-

6A. INTAKE MANIFOLD (GDI)

53

-

6B.exhaust MANIFOLD (GDI)

57

-

Exhaust Manifold (M8)

59

-

6C. INJECTOR and FUEL PUMP ASSEMBLY (GDI)

60

-

Clamp

60

-

Fuel Low Pressure Pipe (M6)

60

-

Fuel Low Pressure Pipe (M8)

60

-

Fuel Nipple

60

-

Injector and Fuel Pump Assembly (GDI)

60

-

Delivery Pipe and Injector

61

-

-

7 Water Pump and Water Hose Water Pump

65

-

Fuel Feed Pipe

61

-

Fuel High Pressure Regulator

61

-

Fuel Return Pipe

61

-

Injector Holder

61

-

Spacer

61

-

7-1

65

-

Thermostat Case

65

-

Water Inlet Pipe

65

-

Water By-Pass Fitting

67

-

Water Fitting

67

-

-

8 Rocker Arms and Camshafts

70

-

Water Pipe

67

-

8-1

70

-

Rocker Arm Shaft

70

-

Rocker Cover

70

-

Beam Camshaft Cap (M8)

74

-

8A. ROCKER COVER and CAMSHAFTS (MIVEC)

85

-

8B.rocker ARMS and ROCKER SHAFT CAPS (MIVEC)

90

-

-

9 Cylinder Head and Valves

92

-

9-1

92

-

10-1

106

-

-

10 Front Case and Oil Pump

106

-

11-1

113

-

-

11 Piston and Connecting Rod

113

-

12 Crankshaft, Cylinder Block, Flywheel and Drive Plate

121

-

Advertisement

Related Products

-

Mitsubishi 4G9 series

-

Mitsubishi 4G93-DOHC

-

Mitsubishi 4G93-DOHC-GDI

-

Mitsubishi 4G94-DOHC-GDI

-

Mitsubishi 4G93-SOHC

-

Mitsubishi 4G92-SOHC

-

Mitsubishi 4G94-SOHC

-

Mitsubishi 4G92

-

Mitsubishi 4G93

-

Mitsubishi 4g63

Mitsubishi Categories

Air Conditioner

Controller

Projector

Automobile

Engine

More Mitsubishi Manuals

Mitsubishi Carisma (Mark I) с бензиновыми двигателями: 4G92 SOHC 16V 1.6 л (1597 см³) 90-99-103 л.с./66-73-76 кВт, 4G93 16V SOHC/DOHC MSX/GDI 1.8 л (1834 см³) 116-122-125-140 л.с./85-90-92-103 кВт; Руководство по эксплуатации, техническому обслуживанию и ремонту, технические характеристики, электросхемы, устройство, диагностика, особенности конструкции. Иллюстрированное практическое пособие легковой автомобиль малого класса Мицубиси Харизма (Каризма) с цельнометаллическими несущими кузовами пятидверный хэтчбек и четырёхдверный седан переднеприводные модели первого поколения выпуска с 1995 по 2004 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео Mitsubishi Carisma замена стоек передних амортизаторов и радиатора печки системы охлаждения (Мицубиси Харизма 95-04)

Mitsubishi Carisma общая информация (Мицубиси Харизма 1995-2004)

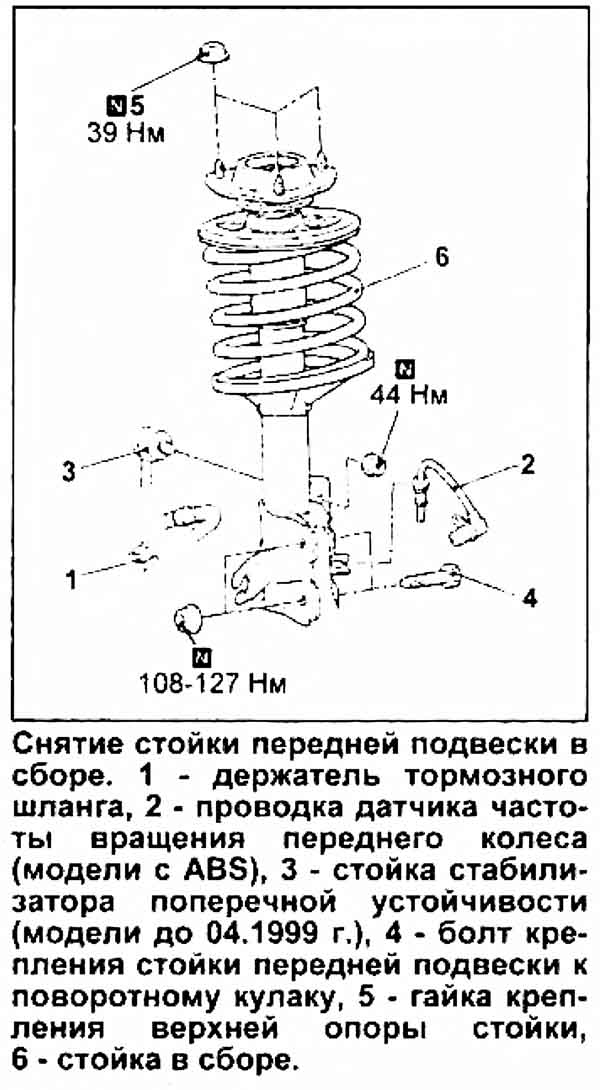

Стойка передней подвески

Снятие

1. Снятие деталей производится в порядке номеров, указанных на рисунке «Снятие стойки передней подвески в сборе».

2. Перед тем, как отвернуть болты крепления стойки передней подвески к поворотному кулаку, подвесьте нижний рычаг на проволоке.

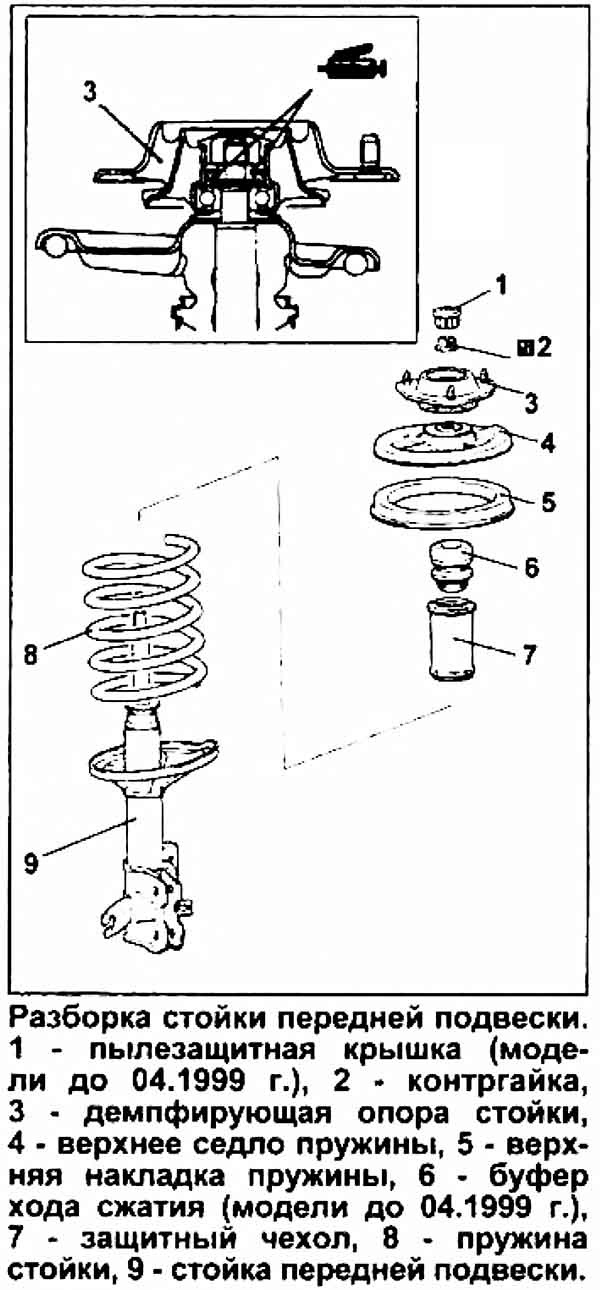

Разборка

1. Разборка производится в порядке номеров, указанных на рисунке «Разборка стойки передней подвески».

2, При разборке обратите внимание на операцию по отворачивания контргайки,

а) С помощью специального инструмента сожмите пружину стойки.

Внимание:

— Установите рычаги стяжки так, чтобы их максимальная длина не превышала длины пружины.

— Не применяйте пневматический инструмент (ударный гайковерт) при затяжке болта стяжки.

б) Удерживая верхнюю чашку пружины с помощью ключа, отверните контргайку.

Внимание: не применяйте пневматический инструмент (ударный гайковерт).

Проверка

1. Проверьте целостность и отсутствие повреждений резиновых элементов,

2. Проверьте пружину на отсутствие

деформаций и повреждений.

3. Убедитесь в отсутствии деформации амортизатора.

4. Проверьте амортизатор на отсутствие утечек.

5. Проверьте подшипник на отсутствие загрязнений и коррозии.

Сборка

1. Сборка производится в порядке, обратном разборке,

2. При сборке обратите внимание на операцию по установке самоконтрящейся гайки.

а) Сожмите пружину при помощи стяжки и временно затяните самоконтрящуюся гайку.

б) Расположите отверстие верхней чашки пружины и отверстие нижней чашки пружины на одной линии.

Примечание: воспользуйтесь подходящей трубкой.

в) Корректно расположите края обоих витков пружины в канавках седел, затем ослабьте затяжку стяжки.

г) Используя ключ, затяните контргайку.

Примечание: не применяйте пневматический инструмент (ударный гайковерт) при затяжке контргайки.

Момент затяжки …………. 78 Нм

Установка

1. Установка деталей осуществляется в порядке, обратном снятию.

2. После завершения установки деталей выполните следующие операции.

а) Проверьте защитные чехлы шаровых шарниров.

б) Проверьте и при необходимости отрегулируйте углы установки передних колес.

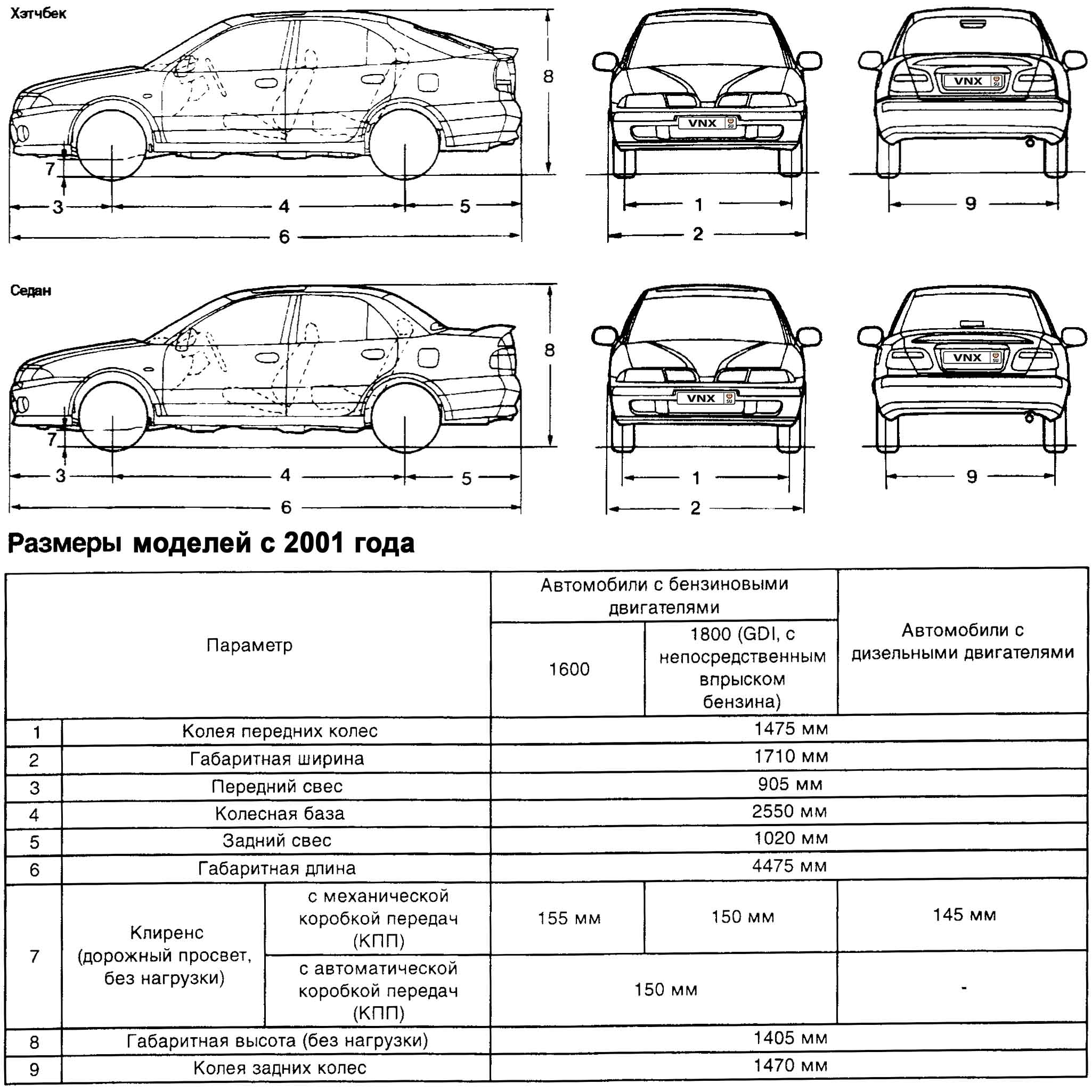

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 4475 |

| 2 | Ширина (без/с зеркалами) / Width | 1710 |

| 3 | Высота (загружен/пустой) / Height | 1405 |

| 4 | Колёсная база / Wheelbase | 2550 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 150 |

| 6 | Снаряжённая масса / Total (curb) weight | 1260 |

| Полная масса / Gross (max.) weight | 1750 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Бензиновый, жидкостного охлаждения, четырехтактный, 4G93 |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 4-цилиндровый, рядный, 16V, DOHC с верхним расположением двух распределительных валов |

| 9 | Диаметр цилиндра / Bore | 81.0 мм |

| 10 | Ход поршня / Stroke | 89.0 мм |

| 11 | Объём / Engine displacement | 1834 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Непосредственный впрыск топлива GDI |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 10.5:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 90 кВт (122 л.с.) при 5500 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 174 Нм при 3750 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | Гидротрансформатор с блокировкой/ Torque Converter |

| 17 | КПП / Transmission type | F4A42 АКПП 4 Автоматическая, четырёхступенчатая, гидромеханическая |

О Книге

- Название: Mitsubishi Carisma 1995-2003 Устройство, техническое обслуживание и ремонт

- Бензиновые двигатели: 4G92 SOHC 16V 1.6 л (1597 см³) 90-99-103 л.с./66-73-76 кВт, 4G93 16V SOHC/DOHC MSX/GDI 1.8 л (1834 см³) 116-122-125-140 л.с./85-90-92-103 кВт

- Выпуск с 1995 года

- Серия: «Ремонт Автомобилей»

- Год издания: 2012

- Автор: Коллектив авторов

- Издательство: «Ассоциация независимых издателей»

- Формат: PDF

- Страниц в книге: 481

- Размер: 325.54 МБ

- Язык: Русский

- Количество электросхем: более 50

4G92 SOHC and 4G92 DOHC MIVEC engine also are used on Mitsubishi Colt sixth generation (1992-2000), a supermini car built by Mitsubishi. This document mostly gives information on general maintenance on overhaul of Mitsubishi engine type above, inspecting and adjusting also given, with pictures and words work together explains things quickly.

This Workshop Manual contains procedures for removal, disassembly, inspection, adjustment, reassembly and installation, etc. for service mechanics.

All information, illustrations and product descriptions contained in this manual are current as at the time of publication. We, however, reserve the right to make changes at any time without prior notice or obligation.

CONTENTS

- GENERAL INFORMATION

- 1. SPECIFICATIONS

- SERVICE SPECIFICATIONS

- REWORK DIMENSIONS

- TORQUE SPECIFICATIONS

- NEW TIGHTENING METHOD–BY USE OF BOLTS TO BE TIGHTENED IN PLASTIC AREA

- SEALANT

- FORM-IN-PLACE GASKET

- 2. SPECIAL TOOLS

- 3. ALTERNATOR AND IGNITION SYSTEM

- 4. TIMING BELT

- 5. FUEL AND EMISSION CONTROL SYSTEM

- 5a. THROTTLE BODY AND EGR SYSTEM (GDI)

- 6. INTAKE AND EXHAUST MANIFOLD

- 6a. INTAKE MANIFOLD (GDI)

- 6b.EXHAUST MANIFOLD (GDI)

- 6c. INJECTOR AND FUEL PUMP ASSEMBLY (GDI)

- 6d.INTAKE AND EXHAUST MANIFOLD <4G94–GDI for PAJERO io>

- 7.WATER PUMP AND WATER HOSE

- 8. ROCKER ARMS AND CAMSHAFTS

- 8a.ROCKER COVER AND CAMSHAFTS (MIVEC)

- 8b.ROCKER ARMS AND ROCKER SHAFT CAPS (MIVEC)

- 9. CYLINDER HEAD AND VALVES

- 10. FRONT CASE AND OIL PUMP

- 11. PISTON AND CONNECTING ROD

- 12.CRANKSHAFT, CYLINDER BLOCK, FLYWHEEL AND DRIVE PLATE

Pub. No.: PWEE9502-I

Language: English

Format: PDF

Pages: 173

Mitsubishi 4G9 (4G92, 4G93, 4G94) Series Engine Repair Manual PWEE9502-I PDF free online