-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

User’s

Manual

Model

GX10/GX20/GP10/GP20/GM10

Communication Command

User’s Manual

IM 04L51B01-17EN

9th Edition

Related Manuals for YOKOGAWA GX10

Summary of Contents for YOKOGAWA GX10

-

Page 1

User’s Manual Model GX10/GX20/GP10/GP20/GM10 Communication Command User’s Manual IM 04L51B01-17EN 9th Edition… -

Page 3: Introduction

YOKOGAWA is strictly prohibited. • The TCP/IP software of this product and the documents concerning it have been developed/created by YOKOGAWA based on the BSD Networking Software, Release 1 that has been licensed from the Regents of the University of California.

-

Page 4: Recorder Version And Functions Described In This Manual

Recorder Version and Functions Described in This Manual Edition Product Explanation GX/GP: Version 1.01 and later — GX/GP: Version 1.02 and later Feature additions. GX/GP: Version 1.03 and later Electromagnetic relay type analog input modules have been added. Feature additions. GX/GP: Version 2.01 and later Support for GX20/GP20 large memory type and expandable I/O has been added.

-

Page 5: How To Use This Manual

For details on the features of the recorder and how to use it, see the following manuals. • Model GX10/GX20/GP10/GP20 Paperless Recorder First Step Guide (IM 04L51B01- 02EN) • Model GX10/GX20/GP10/GP20 Paperless Recorder User’s Manual (IM 04L51B01-01EN) •…

-

Page 6

Blank… -

Page 7: Table Of Contents

Contents Introduction …………………………i Recorder Version and Functions Described in This Manual …………..ii How to Use This Manual ……………………..iii Conventions Used in This Manual ………………….iii Chapter 1 Using Dedicated Commands (General) Operations over an Ethernet Network ……………..1-1 1.1.1 Preparing the Instrument ………………….1-1 1.1.2 Sending Commands and Receiving Responses …………..1-1 Operations over the Serial Interface (RS-232, RS-422/485, USB, Bluetooth) ….

-

Page 8

Contents 2.10.15 Modbus Communication Log (FLog) ………………2-139 2.10.16 FTP Client Log (FLog) ………………….2-140 2.10.17 SNTP (Time Adjustment) Client Log (FLog) ……………2-141 2.10.18 E-Mail Client Log (FLog) ………………..2-142 2.10.19 Web Log (FLog) …………………….2-143 2.10.20 SLMP Log (FLog) …………………..2-144 2.10.21 Control Alarm Summary (FLog) ………………2-145 2.10.22 Control Summary (FLog) ………………..2-146 2.10.23 Detail Event Log Output (FEventLog) (/AS) ……………2-148 2.10.24 External Storage Medium and Internal Memory File List (FMedia) ……..2-157… -

Page 9: Chapter 1 Using Dedicated Commands (General)

Configure the recorder to connect to the Ethernet network that you want to use. For instructions on how to configure the recorder, see section 1.17, “Configuring the Ethernet Communication Function“ in the Model GX10/GX20/GP10/GP20 Paperless Recorder User’s Manual (IM 04L51B01-01EN) or section 2.18, “Configuring the Ethernet Communication Function,”…

-

Page 10: Preparing The Instrument

Configure the recorder to use serial communication. For instructions on how to configure the recorder, see section 1.18, “Configuring the Serial Communication Function (/C2 and / C3 options)“ in the Model GX10/GX20/GP10/GP20 Paperless Recorder User’s Manual (IM 04L51B01-01EN) or section 2.19, “Configuring the Serial Communication Function (/ C3 option),”…

-

Page 11: Connection Procedure (Gx/Gp)

1.2 Operations over the Serial Interface (RS-232, RS-422/485, USB, Bluetooth) 1.2.3 RS-232 Connection Procedure (GX/GP) Connect a cable to the 9-pin D-sub RS-232 connector. Connection • Connector pin arrangement and signal names Each pin corresponds to the signal indicated below. The following table shows the signal name, RS-232 standard, JIS, and ITU-T standard signals.

-

Page 12

1.2 Operations over the Serial Interface (RS-232, RS-422/485, USB, Bluetooth) Handshaking When using the RS-232 interface for transferring data, it is necessary for equipment on both sides to agree on a set of rules to ensure the proper transfer of data. The set of rules is called handshaking. -

Page 13

1.2 Operations over the Serial Interface (RS-232, RS-422/485, USB, Bluetooth) • CS-RS Data transmission control Hardware handshaking is performed between the GX/GP and the PC. When the CS signal becomes False while sending data to the PC, the GX/GP stops the data transmission. -

Page 14: Rs-422/485 Connection Procedure

RS-422/485 Port Converter SDA(–) TD(–) SDB(+) TD(+) RDA(–) RD(–) RDB(+) RD(+) SHIELD EARTH There is no problem of connecting a 220-Ω terminator at either end if YOKOGAWA’s PLCs or temperature controllers are also connected to the communication line. IM 04L51B01-17EN…

-

Page 15

1.2 Operations over the Serial Interface (RS-232, RS-422/485, USB, Bluetooth) • Four-wire system Generally, a four-wire system is used to connect to a host device. In the case of a four- wire system, the transmission and reception lines need to be crossed over. Terminator (external) 120 Ω… -

Page 16

The recommended converter is given below. SYSMEX RA CO.,LTD./MODEL RC-770X, LINE EYE/SI-30FA, YOKOGAWA/ML2 Some converters not recommended by Yokogawa have FG and SG pins that are not isolated. In this case, do not follow the diagram on the previous page (do not connect anything to the FG and SG pins). -

Page 17: Usb Connection Procedure (Gm)

1.2 Operations over the Serial Interface (RS-232, RS-422/485, USB, Bluetooth) 1.2.5 USB Connection Procedure (GM) The procedure to connect a GM to the PC via USB is shown below. For instructions on how to use the PC, see the user’s manual for your PC. Configuring the GM Turn the USB communication function on (default value is on).

-

Page 18: Bluetooth Connection Procedure (Gm, /C8 Option)

1.2 Operations over the Serial Interface (RS-232, RS-422/485, USB, Bluetooth) 1.2.6 Bluetooth Connection Procedure (GM, /C8 option) The procedure to connect a GM to the PC via Bluetooth is shown below. For instructions on how to use the PC, see the user’s manual for your PC. Configuring the GM Turn the Bluetooth function on (default value is on).

-

Page 19: Chapter 2 Commands And Responses

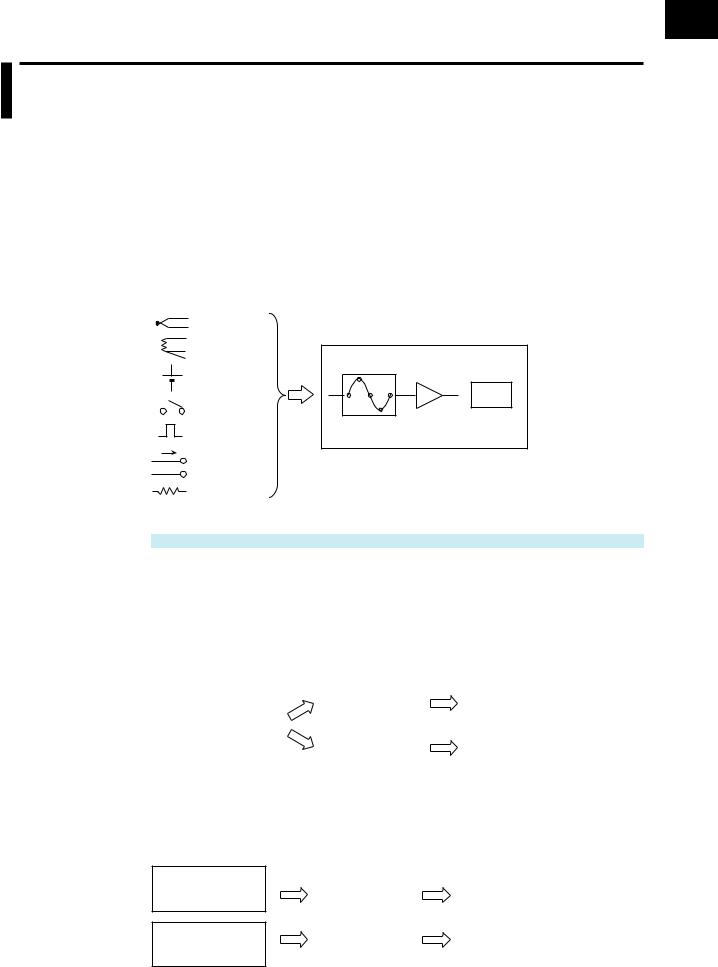

Chapter 2 Commands and Responses Command Transmission and Recorder Responses 2.1.1 General Communication The recorder can work with various applications through the use of commands. The communication that is achieved through commands is referred to as “general communication.” 2.1.2 Command Types and Functions The following types of commands are available.

-

Page 20

2.1 Command Transmission and Recorder Responses Notes on Writing Commands in a Series • Only setting commands can be written in a series. • Queries (see the next section) cannot be written in a series. • If there is an error in one of the commands in a series, the commands before it are canceled, and those after it are not executed. -

Page 21

2.1 Command Transmission and Recorder Responses Parameters Parameters are characteristic values that are attached to commands. Notes on Writing Parameters • Write parameters in their appropriate order. • Spaces around and in the middle of parameters are ignored. Exception is the character strings that users specify. -

Page 22: Recorder Responses

2.1 Command Transmission and Recorder Responses 2.1.4 Recorder Responses The recorder returns the following responses to commands. • If the recorder successfully completes the processing of a received output request command, it outputs the requested data. • If the recorder successfully completes the processing of a received command that is not an output request command, it outputs an affirmative response.

-

Page 23: List Of Commands

2-23 SRangeAICurrent Measurement range of current List of Commands input type AI channel 2-24 SRangePulse Measurement range of pulse input channel 2-25 SRangeDI Measurement range of DI Unless specified otherwise, AI, AO, DI, DO, PI, and PID channel represent I/O channel types. 2-25 SRangeDO DO channel operation…

-

Page 24

2.2 List of Commands 2-39 2-49 Waveform display zone (/MC) Date format SZoneCom SDateFormat 2-39 2-49 SScaleCom Scale display (/MC) [GX/GP] SDst Daylight saving time 2-40 2-49 SBarCom Bar graph display (/MC) SLang Language 2-40 2-50 SPartialCom Partial expanded display (/ STemp Temperature unit MC)[GX/GP]… -

Page 25

2.2 List of Commands 2-57 2-69 SModCCmd Modbus client transmission SFavoriteKind Favorite screen [GX/GP] command (/MC) Multi Batch Setting Commands (/BT) Page 2-58 2-69 SServer Server function Batch text SMltTextField 2-58 2-69 SServerEncrypt Server communication SMltFileHead File header encryption 2-69 SMltFileName File naming rule 2-58… -

Page 26: Output Commands

2.2 List of Commands 2-83 2-30 Reference source of EXPV PID control module channel SCtrlCalc SZoneIO and RSP display (zone high limit, zone 2-83 SCtrlFilterSP Remote SP filter low limit) 2-30 2-83 SScaleIO PID control module channel SCtrlRatioSP Remote SP ratio 2-83 display (scale display position, SCtrlBiasSP…

-

Page 27: Operation Commands

2.2 List of Commands 2-99 2-108 FPrgEvent PV event and time event OSLMPRestore Manually restores SLMP (/E4) 2-108 information output (/PG) Individual re-transmission output OtransChAO 2-99 FPrgEnd Program control end signal status (AO channel) control 2-108 OtransAllAO Collective re-transmission output output (/PG) 2-100 (AO channel) control…

-

Page 28: Instrument Information Commands

• User restriction is placed on the operation. Command Applicable Models The following table lists the commands that are invalid SViewAngle GX10, GP10 according to the limitation types (p1 of the SOpeLimit SMultiPattern GX20, GP20 command or p2 of the SUserLimit command). SMultiKind…

-

Page 29: How To Use Commands

2.2 List of Commands 2.2.7 How to Use Commands 2.2.8 Device Nomenclature in Command Descriptions When Using Ethernet • When not using the login function The following nomenclature is used in the command When you connect a PC to the recorder, the recorder descriptions in section 2.4 to distinguish the devices.

-

Page 30: Parameters

Expandable I/O installed 0 to 6 recording GX20-2/GP20-2: 001 to 1000 [GX/GP] When the unit is GX10/GP10 0 to 2 GM10-1: 1 to 500 display data When the unit is GX20/GP20 0 to 9 Module number GM10-2: 1 to 1000…

-

Page 31: Specifying A Range

AI: 1 or 2, AO: 1 or 2, DI: 1 to 8, DO: 1 registered to to 8 GM10: 20 display groups Logic math GX10: 1 to 20 number GX20-1/GX20-2, GM10-1/GM10-2: 1 Modbus server GX10/GP10/GX20-1/GP20-1: 1 to 16 to 50…

-

Page 32: Setting Commands

When specifying a scan interval of 50 ms or Setting Commands less, the number of channels must be within the limits. (For the limits to the number of channels for each scan interval, see the main unit’s User’s Manual (IM 04L51B01-01EN, or IM 04L55B01-01EN).) SScan The shortest scan interval of the modules…

-

Page 33

2.4 Setting Commands 4-wire RTD type 2 If the scan interval is 50 ms or less, the number of installed modules and the number of channels must Scan Mode Integration time (p4) be within their limits. interval (p3) Auto 50Hz 60Hz Common 3 The shortest scan interval of the module must be… -

Page 34

2.4 Setting Commands SBOLmtAI SModeDI Upper and Lower Burnout Limits of AI DI Module Module Sets the mode of a DI module. Syntax Sets the burnout limits for the general signal range of an SModeDI,p1,p2,p3 AI module (excluding current input type AI modules). No /MT SModeDI,p1,p2,p3,p4 Syntax… -

Page 35: Recording Mode

2.4 Setting Commands SScaleOver SMemKeyConfirm Detection of Values That Exceed the Record Confirmation Action [GX/GP] Scale Sets the record confirmation action. Syntax SMemKeyConfirm,p1 Sets how to detect measurement over-range. Syntax p1 Enable or disable confirmation screen SSclOver,p1 (Off, On) /P1 How to detect values that exceed the Query SMemKeyConfirm? scale…

-

Page 36

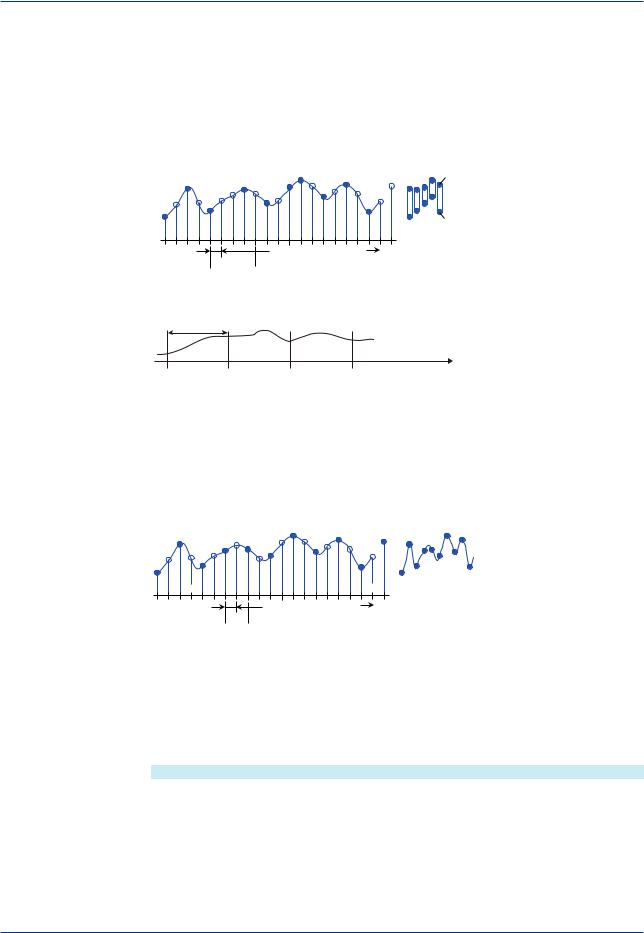

2.4 Setting Commands Scan interval Recording intervals less than or SEventData equal to 50 ms 1ms, 2ms, 5ms, 10ms, 20ms, Event Data Recording 50ms Sets the event data recording mode. 2ms, 10ms, 20ms, 50ms Syntax 5ms, 10ms, 20ms, 50ms SEventData,p1,p2,p3,p4,p5,p6 10ms 10ms, 20ms, 50ms p1 Scan group (1 or 2) -

Page 37

2.4 Setting Commands Description SRecDisp • You cannot use this command to configure settings while recording is in progress. Channel for Recording Display Data • You cannot use this command to configure settings Sets the channel for recording display data. while computation is in progress. -

Page 38

2.4 Setting Commands SRecManual STextField Channel for Recording Manual Sampled Batch Text Data Sets a batch text. Syntax STextField,p1,p2,p3 Sets the channel for recording manual sampled data. Syntax p1 Field number (1 to 24) SRecManual,p1,p2,p3 p2 Title (up to 20 characters, UTF-8) p1 Number (1 to 50) p3 Character string (up to 30 characters, p2 Channel type… -

Page 39

2.4 Setting Commands SFileName SFileFormat File Naming Rule Display/Event Data File Format Sets the file naming rule for data files. Sets the file format of display data files and event data Syntax files. SFileName,p1,p2 Syntax p1 File naming rule SFileFormat,p1 p1 File format (Binary, Text) Date Date… -

Page 40

2.4 Setting Commands p2 Input type (GS) SRangeAI p3 Range (see “Description.”) Measurement Range of AI Channel P4 Calculation type (Scale) p5 Span lower limit Sets the measurement range of an AI channel. Unused Channels p6 Span upper limit Syntax SRangeAI,p1,p2 p7 Bias (–999999 to 999999) p1 Channel number… -

Page 41

2.4 Setting Commands • You cannot use this command to configure settings SRangeAICurrent while computation is in progress. • If p2=TC/RTD/DI/OHM, you cannot specify p4=Sqrt. Measurement Range of Current Input • If p2=GS, you cannot specify p4=Off/Delta. Type AI Channel •… -

Page 42

2.4 Setting Commands p5 Span lower limit p1 Channel number p6 Span upper limit p2 Input type (PulseInput) p7 Bias (–999999 to 999999) p3 Range (LevelRange, ContactRange) p8 Decimal place (0 to 5) LevelRange Level p9 Scaling lower limit ContactRange Contact p10 Scaling upper limit p4 Chattering filter (On, Off) p11 Unit (up to 6 characters, UTF-8) -

Page 43

2.4 Setting Commands • p2=Pulse can be specified when the math function (/ SRangeDI MT) is installed. Measurement Range of DI Channel • If p2=Pulse, p4=Delta or Scale cannot be specified. Sets the measurement range of a DI channel. • p2=Pulse cannot be specified when the operation Unused Channels mode of the DI module is set to Remote. -

Page 44

2.4 Setting Commands Syntax SRangeDO,p1,p2,p3,p4,p5,p6 p5 Span high limit p3= AO_0-20mA 0 to 20000 p1 Channel number p3= AO_4-20mA 4000 to 20000 p2 Output type (Manual) p6 Preset value (0 to 22000) p3 Span lower limit (0 to 1) p7 Reference channel type (Input, Math, P4 Span upper limit (0 to 1) Com) p5 Unit (up to 6 characters, UTF-8) -

Page 45

2.4 Setting Commands SFilter SRjc Sets the First-Order Lag Filter Reference Junction Compensation Method Sets the first-order lag filter of a high-speed AI channel when a high-speed AI module is installed. Sets the reference junction compensation method of an AI Syntax SFilter,p1,p2,p3 channel. -

Page 46

2.4 Setting Commands SAlarmIO,0001,2,On,H,18000,On,DO, SAlarmIO 0205 Description Alarm • You cannot set this on a “Skip” channel. Sets the alarm for an AI, DI, or PI channel. • If p3=Off, you cannot set p4 or subsequent Do Not Set Alarms parameters. -

Page 47

Note SAlmDlyIO,p1,p2,p3,p4 p1 Channel number Green p2 Hour (0 to 24) Blue p3 Minute (0 to 59) Blue violet GX10/GP10 P4 Second (0 to 59) Query GX20/GP20 SAlmDlyIO[,p1]? GM10 Example Set the channel 0001 alarm delay time to 2 Brown minutes 30 seconds. -

Page 48

2.4 Setting Commands SZoneIO SPartialIO Waveform Display Zone Partial Expanded Display [GX/GP] Sets the waveform display zone of an AI, DI, PI, AO, DO, Sets the partial-expansion display of an AI, PI, or PID or PID channel. channel waveform. Syntax Syntax SZoneIO,p1,p2,p3 SPartialIO,p1,p2,p3,p4… -

Page 49

2.4 Setting Commands Query SBandIO[,p1]? SValueIO Example For channel 0001, set a blue band in the range of -0.5000 to 1.0000. Upper/Lower Limit Display Characters SBandIO,0001,In,0,0,255,5000,10000 Sets the upper/lower limit display characters of AI, DI, DO, Description or PID channel. •… -

Page 50

2.4 Setting Commands p16 Input value of uncorrected value 5 SCalibIO p17 Instrument correction coefficient 5 p18 Sensor correction coefficient 5 Calibration Correction p19 Input value of uncorrected value 6 Sets the calibration correction for AI channels. p20 Instrument correction coefficient 6 Disable Calibration Correction p21 Sensor correction coefficient 6 Syntax… -

Page 51

2.4 Setting Commands • For math channels, SPresetAO the specified span Sets the Preset Action upper or lower limit. p3 MAX, MIN, and P-P computation when Sets the preset action of an AO channel. overflow data is detected Syntax SPresetAO,p1,p2,p3,p4 Over Computes using data that p1 Channel number… -

Page 52

2.4 Setting Commands SKConst STlogMath Constant (/MT) TLOG (/MT) Sets a constant for use in computations. Sets the TLOG of a math channel. Syntax Syntax SKConst,p1,p2 STlogMath,p1,p2,p3,p4,p5 p1 Constant number (1 to 100) p1 Channel number p2 Value (–9.9999999E+29 to –1E–30, p2 Timer Type Timer 0, 1E–30 to 9.9999999E+29, eight… -

Page 53

2.4 Setting Commands Query SAlarmMath[,p1[,p2]]? SAlarmMath Example Set a high limit alarm (H) on alarm number 2 of math channel 015. Set the alarm value to 85.0. Alarm (/MT) When an alarm occurs, output to the relay (DO Sets the alarm of a math channel. channel) at number 0105. -

Page 54

2.4 Setting Commands STagMath SBarMath Tag (/MT) Bar Graph Display (/MT) Sets the bar graph display of a math channel. Sets the tag of a math channel. Syntax Syntax STagMath,p1,p2,p3 SBarMath,p1,p2,p3 p1 Channel number p1 Channel number p2 Bar display base position p2 Tag (up to 32 characters, UTF-8) Lower p3 Tag number (up to 16 characters, UTF-8) -

Page 55

2.4 Setting Commands SBandMath SAlmMarkMath Color Scale Band (/MT) Alarm Mark (/MT) Sets the color scale band of a math channel. Sets the display of the marker that indicates the specified Syntax alarm position of a math channel. SBandMath,p1,p2,p3,p4,p5,p6,p7 Syntax p1 Channel number SAlmMarkMath,p1,p2,p3,p4,p5,p6,p7, p8,p9,p10,p11,p12,p13,p14,p15… -

Page 56

2.4 Setting Commands SRangeCom SWDCom Measurement Range (/MC) Watchdog Timer (/MC) Sets the measurement range of a communication Sets the watchdog timer of a communication channel. Channels That Do Not Use Watchdog Timers channel. Syntax Unused Channels SWDCom,p1,p2 Syntax p1 Channel number SRangeCom,p1,p2 p1 Channel number p2 Watchdog timer usage (Off) -

Page 57

2.4 Setting Commands If p7=DO Relay (DO channel) STagCom number If p7=SW Internal switch number Tag (/MC) (001 to 100) Sets the tag of a communication channel. Query SAlarmCom[,p1[,p2]]? Syntax Example Set a high limit alarm (H) on alarm number 2 STagCom,p1,p2,p3 p1 Channel number of communication channel 025. -

Page 58

2.4 Setting Commands Query SBandCom[,p1]? SBarCom Example For communication channel 025, set a blue band in the range of -0.5000 to 1.0000. Bar Graph Display (/MC) SBandCom,025,In,0,0,255,5000,10000 Sets the bar graph display of a communication channel. Description Syntax SBarCom,p1,p2,p3 • You cannot set this on a “Off”… -

Page 59

2.4 Setting Commands SAlmLimit STimer Rate-of-Change Alarm Interval Timer Sets the rate-of-change interval of the rate-of-change Sets a timer. Do Not Use Timers alarm. Syntax Syntax SAlmLimit,p1,p2 STimer,p1,p2 p1 Timer number (1 to 12) p1 Interval for the low limit on rate-of-change alarm p2 Timer type (Off) 1 to 32… -

Page 60

2.4 Setting Commands p6 Interval: Minutes (MM) (00 to 59) SEventAct p7 Timer action Event Action Single Single shot Repeat Repeat Sets an event action. Match Time Timer That Synchronizes Once a Month Syntax SEventAct,p1,p2,p3,p4,p5,p6,p7 Syntax SEventAct,p1,p2,p3,p4,p5,p6,p7,p8 SMatchTimer,p1,p2,p3,p4,p5,p6 SEventAct,p1,p2,p3,p4,p5,p6,p7,p8 p1 Match time timer number (1 to 12) p2 Type (Month) SEventAct,p1,p2,p3,p4,p5,p6,p7,p8, p3 Start time: Day (1 to 28) -

Page 61

Source Action Action Action combinations. For details, see section 1.14 in the Type Element Detail Detail 2 Detail 3 Model GX10/GX20/GP10/GP20 Paperless Recorder Number Rising, Recording Memory Start, ALL, batch User’s Manual (IM 04L51B01-01EN) or section 2.15, Falling, Stop group “Configuring the Event Action Function,”… -

Page 62

2.4 Setting Commands SReport SRepData Report Type (/MT) Report Data (/MT) Sets the type of report to create. Sets the data type and file type of reports. No Reports Syntax SRepData,p1,p2,p3,p4,p5,p6 Syntax p1 Data type 1 (Max, Min, Ave, Sum, Inst) SReport,p1 p1 Type (Off) p2 Data type 2 (Off, Max, Min, Ave, Sum,… -

Page 63

Easy to view from above Lower Easy to view from below Query SViewAngle? Example Set the view angle so that it is easy to view from above. SViewAngle,Upper Description • This command is valid for the GX10/GP10. 2-45 IM 04L51B01-17EN… -

Page 64

2.4 Setting Commands SBackColor SBarDirect Screen Background Color [GX/GP] Bar Graph Display Direction [GX/GP] Sets the screen background color. Sets the bar graph display direction. Syntax Syntax SBackColor,p1,p2,p3 SBarDirect,p1 p1 R value of RGB background colors (0 to p1 Direction 255) Horizontal Horizontal p2 G value of RGB background colors (0 to… -

Page 65

2.4 Setting Commands STrdScale STrdRate Scale [GX/GP] Trend Interval Switching [GX/GP] Set the scale. Sets the trend interval switching. Syntax Syntax STrdScale,p1,p2,p3 STrdRate,p1,p2 p1 Number of digits to display for scale p1 Trend interval switching values. Not switch Normal Normal Switch Fine Fine… -

Page 66

2.4 Setting Commands SMsgBasic STripLine Display Group Trip Line Message Writing Sets the message writing operation. Sets a trip line for a display group. Syntax Syntax STripLine,p1,p2,p3,p4,p5,p6,p7,p8 SMsgBasic,p1,p2,p3 p1 Message writing method p1 Group number (GX/GP: Common, Separate) p2 Trip line number (1 to 4) (GM: Common) p3 Enable or disable (Off, On) Write messages to all display… -

Page 67: Date Format

2.4 Setting Commands Display the month using Letter STimeZone characters (Jan, Feb, Mar, Apr, May, Jun, Jul, Aug, Sep, Time Zone Oct, Nov, Dec) Sets the time zone. Syntax Query STimeZone,p1,p2 SDateFormat? Example Set the date format to “year, month, day,” and p1 Time zone: Hour (-13 to 13) p2 Time zone: Minute (0 to 59) display the month using numerals.

-

Page 68

2.4 Setting Commands STemp SFailSts Temperature Unit Instrument Status to Output (/FL) [GX/ Sets the temperature unit. Syntax STemp,p1 Sets the instrument status to output from the fail relay (DO p1 Temperature unit channel). Syntax Celsius SFailSts,p1,p2,p3,p4,p5 p1 Memory/media status (Off, On) Fahrenheit Query p2 Measurement error (Off, On) -

Page 69

Sets touch and warning sounds. 1.18.11, “Setting USB Input Devices (/UH option)” Syntax SSound,p1,p2 in the Model GX10/GX20/GP10/GP20 Paperless p1 Touch sound (Off, On) Recorder User’s Manual (IM 04L51B01-01EN). p2 Warning sound (Off, On) Query… -

Page 70

1.18.11, alarms are in the alarm state. p4 Power supply “Setting USB Input Devices (/UH option)” in the Model GX10/GX20/GP10/GP20 Paperless Recorder User’s Last Output the previous value Manual (IM 04L51B01-01EN). Output 1… -

Page 71

For details on data types, registers, and channel SClient,FTP,On types, see section 4.5.1, “Modbus Client and Master Description Function” in the Model GX10/GX20/GP10/GP20 • Modbus client is valid on models with the /MC Paperless Recorder User’s Manual (IM 04L51B01- communication channel option. -

Page 72

2.4 Setting Commands p1 Automatic IP address acquisition (On) SClientEncrypt p2 DNS information acquisition (Off, On) p3 Automatic host name registration (Off, On) Client Communication Encryption Query SDhcp? Example Automatically obtain the IP address and DNS Sets whether to encrypt FTP client communication and SMTP client communication. -

Page 73

2.4 Setting Commands SSmtpCnct SFtpTime SMTP Client Connection Destination FTP Transfer Time Shift Server Sets the amount of time to shift file transfers that are carried out by the FTP client function. Sets the SMTP client connection destination server Syntax Syntax SFtpTime,p1,p2 SSmtpCnct,p1,p2,p3,p4,p5… -

Page 74

2.4 Setting Commands SMail SMailAlarm Destination and Behavior for Each Mail Alarm Notification Mail Target Channels Type Detects the alarm status of the specified channels and sends alarm notifications. Sets the destination and behavior for each mail type. Syntax Alarm Notification SMailAlarm,p1 Syntax p1 Channel string (up to 249 characters, up… -

Page 75

2.4 Setting Commands SMailTime SModCList Scheduled Transmission Times Modbus Client Connection Destination Server (/MC) Sets the scheduled transmission times. Syntax SMailTime,p1,p2,p3,p4 Sets the Modbus client connection destination server. p1 Recipient (1 or 2) Syntax SModCList,p1,p2,p3 p2 Reference time: Hours (HH) (00 to 23) p1 Registration number p3 Reference time: Minutes (MM) (00 to 59) p2 Server name (up to 64 characters, ASCII) -

Page 76

Query SServerEncrypt[p1]? types, see section 4.5.1, “Modbus Client and Master Example Encrypt FTP server communication. Function” in the Model GX10/GX20/GP10/GP20 SServerEncrypt,FTP,On Paperless Recorder User’s Manual (IM 04L51B01- 01EN) or section 4.5.1, “Modbus Client/Master Function,” in the Data Acquisition System GM User’s SKeepAlive Manual (IM 04L55B01-01EN). -

Page 77

2.4 Setting Commands SModLimit SWattData Modbus Server Connection Limit WT Data Allocation to Communication Channel (/E2) Enables or disables the Modbus server connection limit function. Allocates WT data to a communication channel. Syntax SModLimit,p1 Syntax SWattData,p1,p2,p3,p4,p5,p6,p7 p1 Connection limit (Off, On) p1 Allocation No Query SModLimit? -

Page 78

2.4 Setting Commands SKdcCnct SDarwinPortLimit KDC Connection Destination (/AS) Port limitation of DARWIN compatible communication Sets the KDC server for the password management. Syntax SKdcCnct,p1,p2,p3 If port limitation is on, port number 34151 only allows p1 Connection destination (Primary, reading of instantaneous data. Secondary) Syntax SDarwinPortLimit,p1… -

Page 79

Edge relay Hexadecimal BIT Syntax SSLMPCCmd,p1,p2,p3,p4,p5,p6,p7,p8, Link relay Hexadecimal BIT p9,p10,p11,p12,p13 Data register Hexadecimal INT16/UINT16/ p1 Command number (GX10/GP10: 1 to 50, INT32/UINT32/ GX20-1/GP20-1: 1 to 100, GX20-2/GP20- FLOAT Link register Hexadecimal INT16/UINT16/ 2/GM10-2: 1 to 200) INT32/UINT32/ p2 Type… -

Page 80

2.4 Setting Commands P6 Enable or disable user ID (On, Off) SOpeLimit Query SSecurity? Example Use the login function when operating the Operation Lock Details [GX/GP] recorder directly or via communication. When Sets which operations to lock. logged in, automatically log out if there is no Syntax SOpeLimit,p1,p2 user activity for 5 minutes. -

Page 81

2.3.1, “Logging In“ in the Model • You cannot enter NULL or spaces in p4 or p5. GX10/GX20/GP10/GP20 Advanced Security Function • For the characters that you can use in the specified (/AS) User’s Manual (IM 04L51B01-05EN) or section… -

Page 82

2.4 Setting Commands SUserLimit SSignIn Authority of User Sign In (/AS) Sets user operation limitations. Sets the sign in record for the measured data file. Syntax Syntax SUserLimit,p1,p2,p3 SSignIn,p1,p2,p3 p1 User limitation number (1 to 10) p1 Sign in type (Batch, File) p2 Authority of user p2 Sign in at record stop Memory… -

Page 83

2.4 Setting Commands SBTPassword SWebTimeOut Bluetooth Password (/C8) [GM] Web Auto Logout (/AS) [GM] Sets the Bluetooth password. Sets the auto logout time for web screen. Syntax Syntax SBTPassword,p1,p2 SWebTimeOut,p1 p1 Password usage (On, Off) p1 Auto logout time (Off, 10 min, 20 min, 30 min) p2 Password (up to 20 characters, ASCII) Query… -

Page 84

Watt is an option (/E2). SMonitor,p1,p2 p1 Information type (see the table below) • When p1 = Switch, p2 = 3 or 4 is valid only for the GX10/GP10. p2 Status (see the table below) Information Type Status Description SMultiPattern… -

Page 85

2.4 Setting Commands • Custom display screen (/CG) cannot be shown in a SMultiKind multi panel. Multi Panel [GX/GP] • This command can be used only when the multi batch function (/BT) is disabled. Set the screens to display on the multi panel. •… -

Page 86

2.4 Setting Commands ProgramSelect Program selection (/PG) SHomeKind ProgramRun Program operation (/ Standard Screen [GX/GP] p2 Display group number Set the standard screen. (when p1 is not CustomDisplay) For Multi Panel Customized display screen number (1 to Syntax SHomeKind,p1,p2,p3 p1 Screen type (Multi) (when p1 is CustomDisplay) p2 Multi panel number (1 to 20) Control group number (1 to 10) -

Page 87

2.4 Setting Commands p1 Batch group number (1 to the number SFavoriteKind used) p2 Field number (1 to 24) Favorite Screen [GX/GP] p3 Title (up to 20 characters, UTF-8) Set the favorite screen. p4 Character string (up to 30 characters, For Multi Panel UTF-8) Syntax… -

Page 88

2.4 Setting Commands SMltSclBmp [GX/GP] SMltGroup Scale Bitmap Display Group Sets the display group’s scale bitmap file for multi batch. Sets the display group for multi batch. Syntax Syntax SMltSclBmp,p1,p2,p3 SMltGroup,p1,p2,p3,p4,p5 p1 Batch group number (1 to the number p1 Batch group number (1 to the number used) used) p2 Display group number… -

Page 89

2.4 Setting Commands SMltMultiKind SBTTimeOut Multi Panel Type Bluetooth Communication Timeout (/C8) [GM] Sets the multi panel pattern for multi batch. Syntax SMltMultiKind,p1,p2,p3,p4,p5 Sets the Bluetooth communication timeout. p1 Batch group number (1 to the number Syntax SBTTimeOut,p1 used) p1 Timeout function (Off, 1min, 2min, 5min, p2 Registration number (1 to 20) 10min) Query… -

Page 90

2.4 Setting Commands Query SSchedule[,p1]? SWebCustomMenu Example Set schedule number 1 with the date set to December 24, 2015, the notification set to 5 Web Monitor Screen days before, and the renotification interval to Sets the contents displayed on the monitor screens. 1 hour. -

Page 91

2.4 Setting Commands SMasterScanGrp SCtrlScan Master Scan Interval Control Period Sets the master scan interval when the measurement Sets the control period. Syntax mode is set to dual interval. SCtrlScan,p1,p2,p3 Syntax p1 Unit number SMasterScanGrp,p1 p1 Scan group number (1 or 2) Fixed to “–”. -

Page 92

2.4 Setting Commands SCtrlLoopAction SCtrlSPPID Loop Control Number of SP Groups, Number of PID Groups Sets the loop control. Syntax SCtrlLoopAction,p1,p2,p3,p4,p5,p6 Sets the number of SP groups, number of PID groups p1 Loop number Syntax SCtrlSPPID,p1,p2,p3 p2 PID initial value p1 Loop number Temperature PIDDef_TEMP… -

Page 93

2.4 Setting Commands SCtrlDIRegist,0,2,A-M_LP1,DI1 SCtrlDIRegist Description Contact Registration • This command is valid when a PID Control Module is installed. Registers a contact Syntax • SCtrlDIRegist,p1,p2,p3,p4 ALM*_Lx(*=1 to 4, x=1 or 2) indicates the alarm p1 Unit number status. ALM*_OUT_Lx(*=1 to 4, x=1 or 2) indicates the alarm output status including the relay action. -

Page 94

2.4 Setting Commands p3 action p4 options p3 action p4 options Description Option ALM1_ ALM1_ Description Option ALM1_ ALM1_ Conditions Conditions DI1 to L1 to L2 to DI1 to L1 to L2 to in which in which ALM4_ ALM4_ ALM4_ ALM4_ p3 is valid p3 is valid… -

Page 95

2.4 Setting Commands p3 action p4 options SCtrlRelay Description Option ALM1_ ALM1_ Conditions DI1 to L1 to L2 to DO Terminal Action (Relay Action) in which ALM4_ ALM4_ p3 is valid DO1 to Sets the DO terminal action (relay action) of a PID when p4 is ALO1_ ALO1_… -

Page 96

2.4 Setting Commands Example Set DO1 of module number 2 connected to DI5 status output COMMON DI6 status output COMMON the main unit to manual and energize. DI7 status output COMMON SCtrlRelay,0,2,DO1,Manual,Energ DI8 status output COMMON Description AI1_BOUT AI1 burnout COMMON AI1_ADERR AI1 AD error… -

Page 97

2.4 Setting Commands p9 Bias (–999999 to 999999) p2 Module number p10 Decimal Place (0 to 5) p3 AI terminal number (AI1, AI2) p11 Scaling low limit p4 Burnout action (Off, Up, Down) Query p12 Scaling high limit SCtrlBurnOut[,p1,p2,p3]? Example When a burnout is detected on AI1 of module p13 Unit (up to 6 characters, UTF-8) number 2 connected to the main unit, set the p14 Low-cut function (Off, On) -

Page 98

2.4 Setting Commands p15 Output value of segmental point 5 SCtrlFilter (number of segmental points ≥ 5) p16 Input value of segmental point 6 (number First-Order Lag Filter of segmental points ≥ 6) Sets the first-order lag filter of the AI terminal of the PID p17 Output value of segmental point 6 control module. -

Page 99

2.4 Setting Commands • SCtrlRangeAI p19 Instrument correction factor 5 (number of If the AI channel input type (p4 of the segmental points ≥ 5) command) is set to Skip or DI, you cannot specify p20 Sensor correction factor 5 (number of anything other than p4=Off. -

Page 100

2.4 Setting Commands SCtrlSplitAO SCtrlRangePV Split Computation Control Input Range Sets the split computation of the AO terminal of the PID Sets the control input range. Syntax control module SCtrlRangePV,p1,p2,p3,p4,p5 Syntax SCtrlSplitAO,p1,p2,p3,p4,p5,p6,p7 p1 Loop number p1 Unit number p2 PV range low limit (-30000 to 30000) p2 Module number p3 PV range high limit (-30000 to 30000) p3 AO terminal number (AO1, AO2) -

Page 101

2.4 Setting Commands SCtrlCalc SCtrlRatioSP EXPV/RSP Function Setting Remote SP Ratio Sets the reference source of EXPV and RSP. Sets the remote SP ratio. Syntax Syntax SCtrlCalc,p1,p2,p3,p4 SCtrlRatioSP,p1,p2,p3 p1 Loop number p1 Loop number p2 PVSP number p2 Ratio setting on/off EXPV EXPV2 p3 Ratio value (1 to 9999) -

Page 102

2.4 Setting Commands Relay4 Relay action on hold & ACK SCtrlOutLimit Normal p12 PV velocity alarm time setpoint (min) (0 Output Limiter Function in Manual Mode to 99) Sets the output limiter function in manual mode p13 PV velocity alarm time setpoint (sec) (0 Syntax SCtrlOutLimit,p1,p2 to 59) -

Page 103

2.4 Setting Commands SCtrlSP SCtrlPIDNo SPNo Group Setting 2 (Target Setpoint SPNo Group Setting 4 (PID Group Alarm) Number) Sets the target setpoint Sets the target setpoint PID group number Syntax Syntax SCtrlSP,p1,p2,p3 SCtrlPIDNo,p1,p2,p3 p1 Loop number p1 Loop number p2 Target setpoint number (1 top2 Target setpoint number (1 to

p3 Target setpoint (target setpoint low limit to…

-

Page 104

2.4 Setting Commands SCtrlRefDEV SCtrlPIDTD Zone PID Setting 3 (Reference Deviation) PID Parameter Setting 3 (Derivative Time) Sets the zone PID reference deviation Sets the derivative time Syntax Syntax SCtrlRefDEV,p1,p2,p3 SCtrlPIDTD,p1,p2,p3 Loop number p1 Loop number Reference deviation on/off (Off, On) p2 PID group number (1 toReference deviation (0% to 100% of p3 Derivative time D (0 to 6000)

-

Page 105

2.4 Setting Commands • This command is valid when a PID Control Module is SCtrlRefPara installed. Reference PID Setting 4 (Other Controls) • Set the control output high limit (p3) less than the control output low limit (p4). Sets control parameters Syntax SCtrlRefPara,p1,p2,p3,p4,p5,p6,p7 SCtrlRefPb… -

Page 106

2.4 Setting Commands SCtrlDetail SCtrlAtDetail Control Detail Setting 1 (Tracking, Control Detail Setting 3 (Auto-Tuning Setpoint Limit, Ramp-Rate Time Unit) Details) Sets the tracking, setpoint limit, and ramp-rate time unit Sets the auto-tuning details Syntax Syntax SCtrlDetail,p1,p2,p3,p4,p5,p6 SCtrlAtDetail,p1,p2,p3,p4,p5 Loop number p1 Loop number Type p2 Target setpoint tracking (Off, On) -

Page 107

Sets the control output suppressing function (overshoot- suppressing function) p1 Display group number (1 to 10) Syntax SCtrlOvershoot,p1,p2 GX10/GX20-1/GM10-1: 1 to 5 p1 Loop number GX20-2/GM10-2: 1 to 10 p2 Control output suppressing function p2 Number of divisions (2, 4, 6, -

Page 108

2.4 Setting Commands SCtrlTag SCtrlOutOperate Loop Tag, Tag Comment OUT Value Manual Output Operation Type (Control Group Display) Sets the loop tag and tag comment Syntax SCtrlTag,p1,p2,p3,p4 Sets the OUT value manual output operation type Syntax SCtrlOutOperate,p1 p1 Loop number p2 Tag (up to 32 characters, UTF-8) p1 Confirmation method p3 Tag No. -

Page 109: Display Settings

2.4 Setting Commands SPrgColor SCtrlEventAct Program Control Loop Color Control Event Action Sets the loop color Sets a control event action Syntax When p2 (type) is set to Off SPrgColor,p1,p2,p3,p4 Syntax SCtrlEventAct,p1,p2 p1 Loop number p1 Registration number (1 to 100) p2 R value of RGB colors (0 to 255) p2 Type (Off) p3 G value of RGB colors (0 to 255)

-

Page 110

2.4 Setting Commands Number Number of used of used Type Input/ Status output/ Option strings Type Input/ Status output/ Option strings channels channels output operation content output operation content type type DI (PID PROG/RESET PRG_RST_ACT Pattern number PTNNO_ monitoring Bin BIN_1_R control (for… -

Page 111

2.4 Setting Commands SLogicMath Logic Math Expression (/MT) Sets the logic math expression Syntax SLogicMath,p1,p2,p3 p1 Math number p2 Expression on/off Not Use DO channel Internal switch p3 Channel number p4 Calculation expression (up to 120 alphanumeric characters, UTF-8) Query SLogicMath[,p1]? Example Output the math result of expression… -

Page 112: Output Commands

Output Commands FTransStatAO Latest Re-transmission State Output Outputs the latest re-transmission (AO channel) state FData Syntax FTransStatAO,p1 p1 Fixed to 0 Outputs the Most Recent Channel Data Example Output the re-transmission state. Outputs the most recent I/O channel, math channel, and FTransStatAO,0 communication channel data.

-

Page 113

2.5 Output Commands FStat FSnap Outputs the Recorder Status Snapshot [GX/GP] Outputs the recorder status. Outputs a snapshot data (screen image data) file. Syntax Syntax FStat,p1 FSnap,p1 p1 Status output (0) p1 Screen image data output (GET) Example Acquire screen image data. Status 1 to 4 output FSnap,GET Status 1 to 8 output… -

Page 114

2.5 Output Commands Example Output all the file lists in the DRV0 directory. FEventLog FMedia,DIR,/DRV0/ Outputs a Detail Event Log(/AS) Output the file lists of items 10 to 20 in the DRV0 directory. Outputs an event log. You can specify the event, user, etc. Syntax FMedia,DIR,/DRV0/,10,20 FEventLog,p1,p2,p3,p4,p5… -

Page 115

2.5 Output Commands GROUP SGroup, STripLine, SSclBmp, FCnf SDualGroup SIpAddress, SDns, SDhcp Outputs Setting Data SECURITY SKdc, SSecurity, SOpePass, Outputs the recorder setting data. SOpeLimit, SUser, SUserLimit, Syntax SSignIn, SSignInTitle, SSignInLimit, FCnf,p1 SBTPassword, SWebCustomMenu, p1 Operation SWebTimeOut, SSessionSecurity Read all settings. MULTIBATCH SMltTextField, SMltFileHead, SMltFileName, SMltGroup, Read I/O settings. -

Page 116

2.5 Output Commands FChInfo FBTDevInfo Outputs Decimal Place and Unit Bluetooth Device Information Output Information [GM] Outputs decimal place and unit information. Outputs the Bluetooth device information of the recorder. Syntax Syntax FChInfo,p1,p2 FBTDevInfo,p1 p1 First channel p1 Bluetooth device information output (0) Example Output the Bluetooth device information of the p2 Last channel Example Output the decimal place and unit information… -

Page 117

2.5 Output Commands FPrgPtnInfo,1 FCtrlNo Description SP Number and PID Number Output • This command is valid when the program control function (/PG option) is in use. Outputs the SP number and PID number • Syntax During program operation, if the selected program FCtrlNo,p1,p2 pattern is not being executed, an error occurs. -

Page 118

2.5 Output Commands FPrgPtnCur (/PG) Running Program Pattern Number and Status Output Outputs the running program pattern number and status Syntax FPrgPtnCur Example Output the running program pattern number and status. FPrgPtnCur Description • This command is valid when the program control function (/PG option) is in use. -

Page 119: Operation Commands

OAlarmAck Operation Commands Clears Alarm Output Clears alarm output (performs an alarm ACK). Syntax OAlarmAck,p1 p1 Alarm output clearance (0) OSetTime Example Clear the alarm output. Sets the Time OAlarmAck,0 Individual alarm ACK Sets the time. Syntax Syntax OAlarmAck,p1,p2,p3 OSetTime,p1 p1 Individual alarm output clearance (1) p1 Time to set p2 Channel number…

-

Page 120

2.6 Operation Commands All scan groups You can specify multiple groups at once. Scan group 1 To do so, separate display groups with a Scan group 2 colon. Example When the measurement mode is dual interval, P4 Message string to write (up to 32 apply a trigger to scan group 2. -

Page 121

2.6 Operation Commands • p2 is valid when multi batch is enabled and p1=2 A “Client” folder is created in the specified folder (reset computation). (p1), and the data is saved there. • Omitting p2 is equivalent to specifying all math •… -

Page 122

2.6 Operation Commands • You can specify the following values for OMBRestore the channel number. DO channel number Recovers Modbus manually Internal switch number Resumes command transmission from Modbus client or • You can specify the following values for the Modbus master to devices in which communication errors status. -

Page 123

2.6 Operation Commands OBatComment OLoadConf Sets a Batch Comment Loads Setting Data Sets a batch comment. Loads a setting data file from the recorder external Syntax storage medium into the recorder. OBatComment,p1,p2,p3 Syntax p1 Batch group number OLoadConf,p1,p2,p3,p4 p1 File name (up to 80 characters, ASCII) When multi batch is disabled: Always 1 Specify the path and file name, excluding When multi batch is enabled: 1 to the… -

Page 124

2.6 Operation Commands p1 Apply the settings (0). OLoadConfAll Example Apply the IP address settings. Loads Setting Data at Once OIPApply,0 Description Loads all settings from the specified folder of the external • storage medium. This command applies the IP address settings specified by the SIpAddress, SDhcp, SDns, and SServer Syntax… -

Page 125

2.6 Operation Commands OUsbFApply OSendValue Applies USB Communication Settings Assists Touch Panel Operation Input [GM] [GX/GP] Applies USB communication settings. Assists text input during touch panel operation. Syntax Syntax OUsbFApply,p1 OSendValue,p1,p2 p1 Apply the settings p1 Fixed to 0. Example Apply the USB communication On/Off setting p2 Character string (up to 64 characters, specified with the SUsbFunction command. -

Page 126

2.6 Operation Commands OErrorClear OTransAllAO Clears the Error Display [GM] Collective re-transmission control Clears the error display status from the 7 segment LED. Controls the re-transmission of AO channels collectively Syntax Syntax OErrorClear,p1 OTransAllAO,p1 p1 Error display clear type p1 Re-transmission enabled or disabled. Error display clear Re-transmission is enabled. -

Page 127

2.6 Operation Commands • • Display groups are those specified by the SGroup, This command is valid when a PID Control Module is STripLine, SSclBmp, SMltGroup, SMltTripLine, installed. SMltSclBmp, or SDualGroup commands. • The remote switching (p2=1) operation during program pattern execution is the same as the program switching of program operation (OCtrlMode OCtrlAM command). -

Page 128

2.6 Operation Commands OCtrlMO OCtrlHOLD Sets the Manual Output Setpoint Hold Program Operation (/PG) Syntax Sets the manual output setpoint OCtrlHOLD,p1 Syntax OCtrlMO,p1,p2,p3 p1 Holding of program operation p1 Loop number Release hold P2 Type Hold Example Release the holding of program operation. Numeric input Shutdown (tight shut function) OCtrlHOLD,0… -

Page 129

2.6 Operation Commands OCtrlTSP OCtrlStSeg Sets the Final Target Setpoint (/PG) Sets the Start Segment Number (/PG) Sets the final target setpoint (TSP) Sets the start segment of program operation Syntax Syntax OCtrlTSP,p1,p2 OCtrlStSeg, p1, p2 p1 Loop number p1 Pattern number (1 to 99) P2 Final target setpoint (PV range low limit to P2 Segment number (1 to the number of PV range high limit) -

Page 130

2.6 Operation Commands Example Collectively load program pattern files from the OCtrlLoadPAT “Pattern” folder in the SD memory card. OCtrlLoadPATAll,Pattern,SD Loads a Pattern File (/PG) Description Loads a program pattern file • This command is valid when the program control Syntax OCtrlLoadPAT,p1,p2,p3 function (/PG option) is in use. -

Page 131: Communication Control Commands

Communication CLogin Control Commands Log in over a Communication Path Logs in over a communication path. Syntax CLogin,p1,p2 p1 User name CCheckSum p2 password Sets the Checksum Example Log in using the user name “admin” and password “password.” Sets the presence or absence of checksum. CLogin,admin,password Syntax CCheckSum,p1…

-

Page 132

2.7 Communication Control Commands CBTConnect Starts Bluetooth Communication (/C8) [GM] Starts Bluetooth communication. Syntax CBTConnect,p1 p1 Bluetooth password of the device you want to connect to Example Connect to the device whose Bluetooth password is “PaSswoRD2.” CBTConnect,’PaSswoRD2′ Description • This command is valid only when a Bluetooth password request has been received via Bluetooth communication. -

Page 133: Instrument Information Output Commands

Instrument Information _TYP Output Commands Outputs the Instrument’s Temperature Unit and Daylight Saving Time Installation Information Outputs whether the instrument’s Fahrenheit temperature _MFG unit and daylight saving time setting is enabled or disabled. Outputs the Instrument Manufacturer Syntax _TYP Outputs the instrument manufacturer. Description Syntax _MFG…

-

Page 134

Blank… -

Page 135: Responses To Commands

Responses to Commands This section explains the responses that recorder returns in response to commands. There are three types of responses: affirmative response, negative response, and data output response. 2.9.1 Affirmative Response (For commands other than output request commands) If the recorder successfully completes the processing of a received command that is not an output request command, it returns an affirmative response.

-

Page 136: Data Output Response

2.9 Responses to Commands Response Example 3 In a string of two commands, if error number 10 occurs in the second parameter of the first command and error number 500 occurs in the fifth parameter of the second command, the recorder outputs: E1,10:1:2,500:2:5 Error Messages…

-

Page 137

2.9 Responses to Commands Binary Output The responses to output commands consisting of binary data output requests are in binary. Format The following figure shows the binary output format. The recorder adds a header to the front of binary output data and a checksum at the end. The request data is entered in the data block. -

Page 138: Output In Response To Rs-422/485 Commands

2.9 Responses to Commands Data Block The actual output data. The format varies depending on the output content. For details, see section 2.11, “Format of the Data Block of Binary Output.” Data sum (16 bits, big endian) The data sum block indicates the sum of the data block. Use the CCheckSum command to specify whether to include data sum.

-

Page 139: 2.10 Ascii Output Format

2.10 ASCII Output Format This section explains the ASCII output format. • In the following format descriptions, the terminator is denoted by “<crlf>.” • One space (ASCII code : 0x 20) is denoted by an underscore (_). Consecutive spaces are denoted by alternating underscores (_) and overscores (¯). •…

-

Page 140: Most Recent (Do Channel) Status (Frelay)

2.10 ASCII Output Format mV_¯_¯_¯_¯ mV V_¯_¯_¯_¯_ V ° C_¯_¯_¯_ °C Sign (+ or -) dddddddd Mantissa (00000000 to 99999999; 8 digits) For erroneous data (data status is E), the mantissa is 99999999. If the data status is O (±over), the mantissa is 99999999 (+over) or –99999999 (–over).

-

Page 141

2.10 ASCII Output Format M03:aaa…<crlf> M04:aaa…<crlf> M05:aaa…<crlf> M06:aaa…<crlf> M07:aaa…<crlf> M08:aaa…<crlf> M09:aaa…<crlf> EN<crlf> Unit number Main unit (Space) Expandable I/O or sub unit aaa… Outputs the relay (DO channel) status of module numbers 00 to 09. If the module installed in the corresponding module number is not a DO module, a hyphen is output. -

Page 142: Internal Switch Status (Frelay)

2.10 ASCII Output Format 2.10.3 Internal Switch Status (FRelay) The output in response to the command “FRelay,1” is shown below. Syntax EA<crlf> S001-010:aaaaaaaaaa<crlf> S011-020:aaaaaaaaaa<crlf> S021-030:aaaaaaaaaa<crlf> S031-040:aaaaaaaaaa<crlf> S041-050:aaaaaaaaaa<crlf> S051-060:aaaaaaaaaa<crlf> S061-070:aaaaaaaaaa<crlf> S071-080:aaaaaaaaaa<crlf> S081-090:aaaaaaaaaa<crlf> S091-100:aaaaaaaaaa<crlf> EN<crlf> aaa…a The most recent internal switch status is output. The internal switch status is output 10 channels per line over 10 lines.

-

Page 143

2.10 ASCII Output Format M07:aaa…<crlf> M08:aaa…<crlf> M09:aaa…<crlf> EN<crlf> Unit number Main unit (Space) Expandable I/O or sub unit Outputs the re-transmission (AO channel) states of module numbers 00 to 09. aaa… If the module installed in the corresponding module number is not an AO module, a hyphen is output. -

Page 144: Users Who Are Currently Logged In (Fuser)

2.10 ASCII Output Format 2.10.5 Users Who Are Currently Logged In (FUser) The output in response to the command “FUser,0” is shown below. Syntax EA<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxy<crlf> EN<crlf> Login mode Via general communication Via Web (HTTP server) Via FTP server RS-232, RS-422/485, USB communication, or Bluetooth Via front panel User level…

-

Page 145

2.10 ASCII Output Format The output in response to the command “FUser,2” is shown below. Syntax EA<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxyABCDEFGHIJKLMN<crlf> EN<crlf> Login mode Via general communication Via Web (HTTP server) Via FTP server RS-232, RS-422/485, USB communication, or Bluetooth Via front panel User level Administrator User… -

Page 146: All Users Who Are Currently Logged In (Fuser)

2.10 ASCII Output Format 2.10.6 All Users Who Are Currently Logged In (FUser) The output in response to the command “FUser,1” is shown below. Syntax EA<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxy<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxy<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxy<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxy<crlf> EN<crlf> Login mode Via general communication Via Web (HTTP server) Via FTP server RS-232, RS-422/485, USB communication, or Bluetooth…

-

Page 147

2.10 ASCII Output Format The output in response to the command “FUser,3” is shown below. Syntax EA<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxyABCDEFGHIJKLMN<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxyABCDEFGHIJKLMN<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxyABCDEFGHIJKLMN<crlf> p_l_uuuuuuuuuuuuuuuuuuuu_abcdefghijkmnpqrstuvwxyABCDEFGHIJKLMN<crlf> EN<crlf> Login mode Via general communication Via Web (HTTP server) Via FTP server RS-232, RS-422/485, USB communication, or Bluetooth Via front panel User level Administrator… -

Page 148: Instrument Address (Faddr)

2.10 ASCII Output Format 2.10.7 Instrument Address (FAddr) The output in response to the command “FAddr,IP” is shown below. Syntax EA<crlf> IP_Address_¯_¯_¯:xxx.xxx.xxx.xxx<crlf> Subnet_Mask_¯_¯_:xxx.xxx.xxx.xxx<crlf> Default_Gateway_:xxx.xxx.xxx.xxx<crlf> Primary_DNS_¯_¯_:xxx.xxx.xxx.xxx<crlf> Secondary_DNS_¯_:xxx.xxx.xxx.xxx<crlf> Host_¯_¯_¯_¯_¯_¯:yyyyyyyyyyyyyyyyyyyy…<crlf> Domain_¯_¯_¯_¯_¯:zzzzzzzzzzzzzzzzzzzz…<crlf> EN<crlf> IP address number (0 to 255) Host name (fixed to 64 characters. Unused character positions are filled with yyy…

-

Page 149: Recorder Status (Fstat)

2.10 ASCII Output Format 2.10.8 Recorder status (FStat) The output in response to the command “FStat,0” is shown below. Syntax EA<crlf> aaa.bbb.ccc.ddd<crlf> EN<crlf> The output in response to the command “FStat,1” is shown below. Syntax EA<crlf> aaa.bbb.ccc.ddd.eee.fff.ggg.hhh<crlf> EN<crlf> Status information 1 (see table below) Status information 2 (see table below) Status information 3 (see table below) Status information 4 (see table below)

-

Page 150

2.10 ASCII Output Format Status Information 3 Name Description Computation dropout Set to 1 when computation cannot keep up. Decimal and unit Set to 1 when the decimal or unit information is information setting changed. Command error Set to 1 when there is a command syntax error. Execution error Set to 1 when there is a command execution error. -

Page 151

2.10 ASCII Output Format Status Information 7 Name Description Status Information 8 Name Description 2-133 IM 04L51B01-17EN… -

Page 152: Alarm Summary (Flog)

2.10 ASCII Output Format 2.10.9 Alarm Summary (FLog) The output in response to the command “FLog,ALARM” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss.ttt_kkk_cccc_lss<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss.ttt Time of alarm occurrence Year (1900 to 2099) yyyy Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 153: Message Summary (Flog)

2.10 ASCII Output Format 2.10.10 Message Summary (FLog) The output in response to the command “FLog,MSG” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_YYYY/MO/DD_HH:MM:SS_t_mmm…m_zzz_ggg…g_uuu… u<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time when the message was written yyyy Year (1900 to 2099) Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59)

-

Page 154: Event Log (Flog)

2.10 ASCII Output Format 2.10.11 Event log (FLog) The output in response to the command “FLog,EVENT” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_zzz_-sss…s_uuu…u<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of event occurrence Year (1900 to 2099) yyyy Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 155: Address Setting Log (Flog)

2.10 ASCII Output Format 2.10.13 Address Setting Log (FLog) The output in response to the command “FLog,DHCP” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_kkk…k_mmm…m<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of occurrence yyyy Year (1900 to 2099) Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 156: General Communication Log (Flog)

2.10 ASCII Output Format 2.10.14 General Communication Log (FLog) The output in response to the command “FLog,General” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_nn_uuu…u_fdmmm…m<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of command Tx/Rx Year (1900 to 2099) yyyy Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 157: Modbus Communication Log (Flog)

2.10 ASCII Output Format 2.10.15 Modbus Communication Log (FLog) The output in response to the command “FLog,Modbus” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_c_xxxxxx_kkk…k_nnn_d<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of error occurrence yyyy Year (1900 to 2099) Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 158: Ftp Client Log (Flog)

2.10 ASCII Output Format Detail Meaning BAD_ADDR The address of the response message is invalid (does not match the command). BAD_NUM The register of the response message is invalid (does not match the command). The number of registers in the response message is invalid (does BAD_CNT not match the command).

-

Page 159: Sntp (Time Adjustment) Client Log (Flog)

2.10 ASCII Output Format 2.10.17 SNTP (Time Adjustment) Client Log (FLog) The output in response to the command “FLog,SNTP” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_nnn_xxxxxxxxx<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of error occurrence yyyy Year (1900 to 2099) Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59)

-

Page 160: E-Mail Client Log (Flog)

2.10 ASCII Output Format 2.10.18 E-Mail Client Log (FLog) The output in response to the command “FLog,MAIL” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_ffffff_eeeeeeeeeeee_n_uuu…u<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of transmission Year (1900 to 2099) yyyy Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 161: Web Log (Flog)

2.10 ASCII Output Format 2.10.19 Web Log (FLog) The output in response to the command “FLog,WEB” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_xxx.xxx.xxx.xxx_mmmmmmmm_uuu…u_ccc_nnn…<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of error occurrence yyyy Year (1900 to 2099) Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 162: Slmp Log (Flog)

2.10 ASCII Output Format 2.10.20 SLMP Log (FLog) The output in response to the command “FLog,SLMP” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_xxxxxx_kkk…k_nnn_d<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of command Tx/Rx Year (1900 to 2099) yyyy Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 163: Control Alarm Summary (Flog)

2.10 ASCII Output Format 2.10.21 Control Alarm Summary (FLog) The output in response to the command “FLog,CALARM” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss.ttt_kkk_cccc_lsssss<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss.ttt Time of control alarm occurrence yyyy Year (1900 to 2099) Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59)

-

Page 164: Control Summary (Flog)

2.10 ASCII Output Format 2.10.22 Control Summary (FLog) The output in response to the command “FLog,CTRL” is shown below. Syntax EA<crlf> yyyy/mo/dd_hh:mm:ss_aaa…a_sss…s<crlf> … EN<crlf> yyyy/mo/dd_hh:mm:ss Time of control occurrence Year (1900 to 2099) yyyy Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59) Second (00 to 59)

-

Page 165

2.10 ASCII Output Format Type Description PVH_ _ PV high limit PVL_ _ PV low limit SPH_ _ SP high limit SPL_ _ SP low limit Deviation high limit DVH_ _ DVL_ _ Deviation low limit DVO_ _ Deviation H/L limits DVI_ _ Deviation within H/L limits Control output high limit… -

Page 166: Detail Event Log Output (Feventlog) (/As)

2.10 ASCII Output Format 2.10.23 Detail Event Log Output (FEventLog) (/AS) The output in response to the command «FEventLog» is shown below. Output is possible when the advanced security function (/AS) is enabled. Output from Web operation is possible only when the GM’s advanced security function (/AS) is enabled. Syntax EA<crlf>…

-

Page 167

2.10 ASCII Output Format Operation Event string ### information and detailed information Power off* POWER OFF — Power on* POWER ON — Login* LOGIN — Logout* LOGOUT — User lock out UserLocked User:UUU User number Control Mode change ChgMode ss••• ss•••… -

Page 168

2.10 ASCII Output Format Operation Event string ### information and detailed information Math start MathStart — Math stop MathStop — Math reset MathRST### When multi batch is disabled: (space) When multi batch is enabled: (space) Resetting of all math channels -01 to-12 Resetting of math channels belonging to the specified… -

Page 169

2.10 ASCII Output Format Operation Event string ### information and detailed information Timer reset TimerRST Timer:ttt,ttt,ttt••• List of timer numbers that were reset (ALL for all timers) Match time timer MTimerRST Timer:ttt,ttt,ttt••• reset List of timer numbers that were reset (ALL for all timers) Communication WriteComm kk•••,CCCC=dd•••… -

Page 170

2.10 ASCII Output Format Operation Event string ### information and detailed information Parameter Setting parameter Cert Certificate All settings <Detailed information> —- When ### = Report —- cc•••,rr••• cc••• Report format [EXCEL, PDF] rr••• Report type [Hour, Day, Week, Month, Hour+Day, Day+Week, Day+Month, Batch, Custom] —- When ### = Scale —-… -

Page 171

2.10 ASCII Output Format Operation Event string ### information and detailed information Example: (s,num)=(OFF,3)->(ON,12) When multi batch settings are loaded, if the settings have not changed, the details are not output. Lock the keys Keylock ON — Release the key lock Keylock OFF —… -

Page 172

2.10 ASCII Output Format Operation Event string ### information and detailed information Unit00,Slot:01,2013/06/05,User01 Module activation ApplyModule — Module update UpdateModule Unit:uu,Slot:ss,mm•••,ii•••,vv••• Unit Slot mm••• Module name ii••• Serial number vv••• Version number Setting changes during recording Alarm setting change SetAlarm cccc:l:(s,typ,val,hys,l,Otyp,Ono)=(b1,b2,b3,b4,b5,b 6,b7)->(a1,a2,a3,a4,a5,a6,a7) Channel… -

Page 173

2.10 ASCII Output Format Operation Event string ### information and detailed information The following settings (those that have been changed among the following two settings) input Calibration correction value output Output calibration value Example: 0001:02:(output)=(1.234)->(2.234) Save directory SetDirectory (b1)->(a1) change Folder name Example: (DATA0)->(DATA1) -

Page 174

2.10 ASCII Output Format Operation Event string ### information and detailed information ss••• Setting file name kk••• Setting change type [Security,Comm,I/ OCh,MathCh,CommCh,Other] (list of changed settings) Example: 000111_131219_095412.GSL:Security, Comm,I/OCh,MathCh,CommCh,Other Schedule setting SetSchedule Same as the setting changes during recording. Updating Other updates Update### Action (output in the event string) -

Page 175: External Storage Medium And Internal Memory File List (Fmedia)

2.10 ASCII Output Format 2.10.24 External Storage Medium and Internal Memory File List (FMedia) The output in response to the command “FMedia,DIR” is shown below. Syntax EA<crlf> yy/mm/dd_hh:mi:ss_lll…l_fff…<crlf> yy/mm/dd_hh:mi:ss_<DIR>_dddddddd…<crlf> EN<crlf> yyyy/mo/dd_hh:mm:ss Time of file generation Year (1900 to 2099) Month (01 to 12) Day (01 to 31) Hour (00 to 23) Minute (00 to 59)

-

Page 176: Setting Data (Fcnf)

2.10 ASCII Output Format 2.10.26 Setting Data (FCnf) The output in response to the command “FCnf” is shown below. Syntax EA<crlf> <Response to a setting query> EN<crlf> The setting data is output in the format of the response to a setting query. 2.10.27 Decimal Place and Unit Information (FChInfo) The output in response to the command “FChInfo”…

-

Page 177: System Configuration (Fsysconf)

2.10 ASCII Output Format 2.10.28 System Configuration (FSysConf) The output in response to the command “FSysConf” is shown below. Syntax When no expandable I/O is connected EA<crlf> Unit:00 00:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 01:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 02:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 03:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 04:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 05:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 06:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 07:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 08:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> 09:cccccccccccccccc_uuuuuuuuuuuuuuuu_defghijklmnopqrs<crlf> EN<crlf> When an expandable I/O or sub unit is connected EA<crlf>…

-

Page 178

2.10 ASCII Output Format Output example when an expandable I/O or sub unit is connected • The unit information area (e.g. U00) will contain the expansion module name. All seven units are output regardless of whether expansion modules are available. •… -

Page 179: Bluetooth Device Information (Fbtdevinfo)

2.10 ASCII Output Format (Space) Expandable I/O or sub unit DEFGHIJKLMNOPQRS Expansion module status D to S express the following items. System data error (-: normal, X: error) Ethernet error (-: normal, X: error) F to S Reserved (-) 2.10.29 Bluetooth Device Information (FBTDevInfo) The output in response to the command “FBTDevInfo”…

-

Page 180: Reminder Information Output (Freminder)

2.10 ASCII Output Format 2.10.30 Reminder Information Output (FReminder) The output in response to the command “FReminder” is shown below. Syntax EA<crlf> nn ssssss yyy/mo/dd_YYY/MO/DD_e…<crlf> EN<crlf> Schedule number (01 to 12) ssssss Status None No registration Normal Before notification Notifying Notice After expiration Expire…

-

Page 181: Outputs The Most Recent Control Data (Fctrldata)

2.10 ASCII Output Format 2.10.31 Outputs the Most Recent Control Data (FCtrlData) The output in response to the command “FCtrlData” is shown below. Outputs the most recent control data per loop. Syntax EA<crlf> DATE_yy/mo/dd<crlf> TIME_hh:mm:ss.mmmt<crlf> llll,S_fddddddddE-pp,S_fddddddddE-pp,S_fddddddddE-pp,aaaa1aaaa2aaaa3aaaa4<crlf> EN<crlf> yy/mo/dd Data time (year, month, day) Year (00 to 99) Month (01 to 12) Day (01 to 31)

-

Page 182: Sp Number And Pid Number Output (Fctrlno.)

2.10 ASCII Output Format 2.10.32 SP Number and PID Number Output (FCtrlNo.) The output in response to the command “FCtrlNo” is shown below. Syntax EA<crlf> LOOP,llll<crlf> SPNO,x<crlf> PIDNO,y<crlf> EN<crlf> llll Loop number (L001 to L692) SP number (1 to

PID number (1 to 8, R) Output Example FCtrlNo,L001…

-

Page 183: Control Mode Output (Fctrlmode)

2.10 ASCII Output Format 2.10.33 Control Mode Output (FCtrlMode) The output in response to the command “FCtrlMode” is shown below. Syntax EA<crlf> llll,xxx.xxx.xxx.xxx<crlf> EN<crlf> llll Loop number (L001 to L692) The states of bits 31 to 24, 23 to 16, 15 to 8, and 7 to 0 are indicated in order using decimal notation.

-

Page 184: Program Operation Mode Output (Fprgmode)

2.10 ASCII Output Format 2.10.34 Program Operation Mode Output (FPrgMode) The output in response to the command “FPrgMode” is shown below. Syntax EA<crlf> pp,xxx.xxx.xxx.xxx<crlf> EN<crlf> Program pattern number (1 to 99) The states of bits 31 to 24, 23 to 16, 15 to 8, and 7 to 0 are indicated in order using decimal notation.

-

Page 185: Program Pattern Information Output (Fprgptninfo)

2.10 ASCII Output Format 2.10.35 Program Pattern Information Output (FPrgPtnInfo) The output in response to the command “FPrgPtnInfo” is shown below. Syntax EA<crlf> PTNNO,a<crlf> SEGNO,b<crlf> SEGUSE,c<crlf> SEGTM,hh:mm:ss<crlf> WAITTM,hh:mm:ss<crlf> RPT-MODE,d<crlf> RPT-CNT,e<crlf> RPT-REM,f<crlf> RPT-START,g<crlf> RPT-END,h<crlf> STARTTM,yy/mo/dd hh:mm:ss<crlf> ENDTM,yy/mo/dd hh:mm:ss<crlf> EN<crlf> PTNNO Running pattern number a (1 to 99) SEGNO Running segment number b (1 to 99) SEGUSE…

-

Page 186: Pv Event And Time Event Information Output (Fprgevent)

2.10 ASCII Output Format Output Example EA<crlf> PTNNO,5 SEGNO,10 SEGUSE,7 SEGTM,11:05:22 WAITTM,00:06:00 RPT-MODE,1 RPT-CNT,20 RPT-REM,2 RPT-START,3 RPT-END,6 STARTTM,17/05/03 10:00:00 ENDTM,17/05/05 10:00:00 EN<crlf> 2.10.36 PV event and time event information output (FPrgEvent) The output in response to the command “FPrgEvent” is shown below. Syntax EA<crlf>…

-

Page 187: Program Control End Signal Status Output (Fprgend)

2.10 ASCII Output Format 2.10.37 Program control end signal status output (FPrgEnd) The output in response to the command “FPrgEnd” is shown below. Syntax EA<crlf> pp,x<crlf> EN<crlf> Program pattern number (1 to 99) Program control end signal status 5-second program control end signal is off 5-second program control end signal is on Output Example FPrgEnd,1…

-

Page 188: Instrument Manufacturer (_Mfg)

2.10.40 Instrument’s Product Name (_INF) The output in response to the command “_INF” is shown below. Output Example EA<crlf> ‘GX20/GP20’,123456789,xx-xx-xx-xx-xx-xx,Rx.xx.xx <crlf> EN<crlf> ‘GX20/GP20’ Product name (‘GX20/GP20’, ‘GX10/GP10’, or ‘GM10’) 123456789 Product serial number xx-xx-xx-xx-xx-xx MAC address (xx’s are hexadecimals) Rx.xx.xx Firmware version…

-

Page 189: Instrument’s Basic Specifications (_Cod)

Display language Japanese English Chinese Supply voltage Blank (when the product name is GX10, GX20, or GM10) 100 VAC, 240 VAC (when the product name is GP10 or GP20) Power cord Blank (when the product name is GX10, GX20, or…

-

Page 190: Instrument’s Option Installation Information (_Opt)

2.10 ASCII Output Format 2.10.43 Instrument’s Option Installation Information (_OPT) The output in response to the command “_OPT” is shown below. Output Example EA<crlf> /C2,’RS-232′<crlf> /C3, ‘RS-422/485′<crlf> /C8, ‘Bluetooth'<crlf> /D5, ‘VGA output'<crlf> /FL, ‘Fail output (1 point) ‘<crlf> /MT,’Mathematical function (with report function) ‘<crlf> /MC, ‘Communication channel function'<crlf>…

-

Page 191: Instrument’s Temperature Unit And Daylight Saving Time Installation Information (_Typ)

2.10 ASCII Output Format 2.10.44 Instrument’s Temperature Unit and Daylight Saving Time Installation Information (_TYP) The output in response to the command “_TYP” is shown below. Output Example EA<crlf> DST,’Summer time/Winter time’<crlf> DEGF,’degF’<crlf> EN<crlf> Daylight saving time enabled Fahrenheit temperature unit enabled DEGF 2.10.45 Instrument’s Error Number Information (_ERR) The output in response to the command “_ERR”…

-

Page 192: Instrument’s Unit Configuration Information (_Uns Or

2.10 ASCII Output Format 2.10.46 Instrument’s Unit Configuration Information (_UNS or _UNR) The output in response to the command “_UNS” or “_UNR” is shown below. Syntax EA<crlf> p1,p2,p3,p4,p5,p6,p7,p8,p9,p10<crlf> p1,p2,p3,p4,p5,p6,p7,p8,p9,p10<crlf> … EN<crlf> Output Example EA<crlf> Main,0,’GX20-1J’,1234567,xx-xx-xx-xx-xx-xx,R1.01.01,/MT /C2,0,10,— —————<crlf> Sub,1,’GX90EX-02-ET1’,1234567,xx-xx-xx-xx-xx-xx,R1.01.01,,0,6,—— ————<crlf> EN<crlf> One line (p1 to p10) contains configuration information of a single unit.

-

Page 193: Instrument’s Module Configuration Information (_Mds Or Mdr)

2.10 ASCII Output Format 2.10.47 Instrument’s Module Configuration Information (_MDS or MDR) The output in response to the command “_MDS” or “_MDR” is shown below. Syntax EA<crlf> p1,p2,p3,p4,p5,p6,p7,p8,p9,p10,p11<crlf> p1,p2,p3,p4,p5,p6,p7,p8,p9,p10,p11<crlf> … EN<crlf> Output Example EA<crlf> Main,0,1,’GX90YD-06-11′,1234567,R1.01.01,,0,0,6,—————- <crlf> Main,0,9,’GX90EX-02-ET1’1234567,R1.01.01,,0,0,0,—————- <crlf> Sub,1,0,’GX90XA-10-U2′,1234567,R1.01.01,,0,10,0,—————- <crlf> Sub,1,1,’GX90XA-10-U2′,1234567,R1.01.01,,0,10,0,—————- <crlf>…

-

Page 194

2.10 ASCII Output Format The I/O module information is output (indicated in green below). Without an expandable I/O or sub unit With an expandable I/O or sub unit Main unit Main unit Expansion module AI, DI, etc.: I/O module 2-176 IM 04L51B01-17EN… -

Page 195: 2.11 Format Of The Data Block Of Binary Output

2.11 Format of the Data Block of Binary Output This section explains the data that is stored in the data block in the binary output of data “Binary Output” output response. For the entire structure of the binary output format, see on page 2-119.

-

Page 196

2.11 Format of the Data Block of Binary Output Additional Information (64 bits) Bit 0: Daylight saving time (0: standard time; 1: daylight saving time) Data Type (4 bits) Indicates the data type. (1: 32 bit integer; 2: 32 bit floating point) Data values for channels set to Log scale (/LG) are 32-bit floating-point type. -

Page 197

2.11 Format of the Data Block of Binary Output The eight bit values of alarm 1 to alarm 4 are described in the table below. Value Description 0 to 5 No alarm High limit alarm Low limit alarm Difference high limit alarm Difference low limit alarm High limit on rate-of-change alarm Low limit on rate-of-change alarm… -

Page 198: Channel Fifo Data (Ffifocur)

2.11 Format of the Data Block of Binary Output 2.11.2 Channel FIFO Data (FFifoCur) The output in response to the command “FFifoCur,0” is shown below. Outputs the I/O channel, math channel, and communication channel FIFO data. Configuration Data is stored in “Block 1” shown below. 2 bytes 2 bytes Number of blocks…

-

Page 199: The Most Recent Control Data (Fctrldata)

2.11 Format of the Data Block of Binary Output 2.11.4 The Most Recent Control Data (FCtrlData) The output in response to the command “FCtrlData,1” is shown below. Outputs the most recent control data per loop. The figure below shows the structure of the output data. Data is stored in “Block 1.” 2 bytes 2 bytes Number of blocks…

-

Page 200

2.11 Format of the Data Block of Binary Output Data Time Item (Number of Bits) Value Year (8 bits) 0 to 99 Month (8 bits) 1 to 12 Day (8 bits) 1 to 31 Hour (8 bits) 0 to 23 Minute (8 bits) 0 to 59 Second (8 bits) -

Page 201

2.11 Format of the Data Block of Binary Output Decimal Point Place (16 bits) Indicates the decimal point place. Value Description 0 to 3 0 to 4 4 to 7 0 to 4 8 to 11 Alarm (32 bits) Indicates the alarm status. The eight bit values of alarm 1 to alarm 4 are described in the table below. -

Page 202

2.11 Format of the Data Block of Binary Output PVSEL (8 bits) Indicates the status of PV input. Value Description AI1 is used for PV1. EXPV1 is used for PV1. AI2 is used for PV2. EXPV2 is used for PV2. AI2 is used for PV1 (when PV switching is selected.) EXPV2 is used for PV1 (when PV switching is selected.) PV (32 bits) -

Page 203: Appendix

Appendix Appendix 1 ASCII Character Codes The ASCII character code table is shown below. Upper 4 Bits ‘ (space) “ & ‘ LF (line feed) < (return) • > Characters Used in Commands In addition to alphanumeric characters, the following characters are used: commas as delimiters, semicolons as sub delimiters, question marks as query symbols, single quotation marks to indicate user-defined character strings, and “CR”…

-

Page 204: Appendix 2 Login Procedure

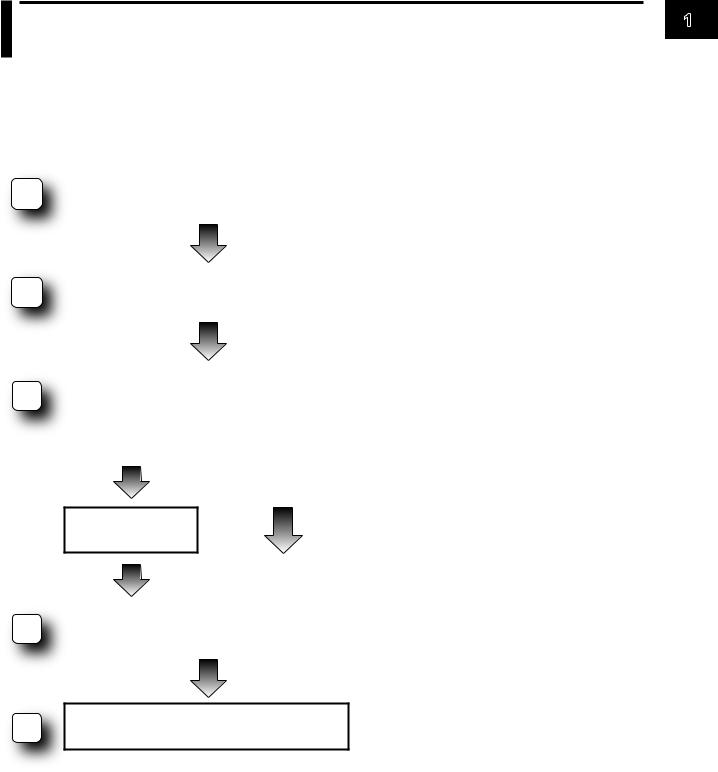

Appendix 2 Login Procedure To communicate using the general communication feature, you must log in to the recorder from your PC. If you complete the procedure successfully up to “Login complete” in the following figure, you will be able to use the commands. When Using the Login Function Connect For Bluetooth, the Bluetooth connection flow…

-

Page 205: When Not Using The Login Function

Appendix 2 Login Procedure When Not Using the Login Function Connect For Bluetooth, the Bluetooth connection flow chart is inserted here (see appendix 7). Within the number E1: 732 of connections? Disconnect Login complete Start Judge E1: 401 Response from the recorder (message omitted) Code Response App-3…

-

Page 206: Appendix 3 Output Flow Chart Of External Storage Medium Files And File Lists

Appendix 3 Output Flow Chart of External Storage Medium Files and File Lists Example for Outputting File aaaa.dtd The flow chart for outputting file aaaa.dtd in the DATA0 directory on the external storage medium is shown below. START Send command FMedia,GET,/DRV0/DATA0/aaaa.dtd,0,-1 Receive response (1) If the binary header flag (bit 0) is 0,…

-

Page 207: Example For Outputting A File List

Appendix 3 Output Flow Chart of External Storage Medium Files and File Lists Example for Outputting a File List The flow chart for outputting the list of files in the DATA0 directory on the external storage medium is shown below. START Send command FMedia,DIR,/DRV0/DATA0/,0,-1…

-

Page 208: Appendix 4 Fifo Data Output Flow Chart

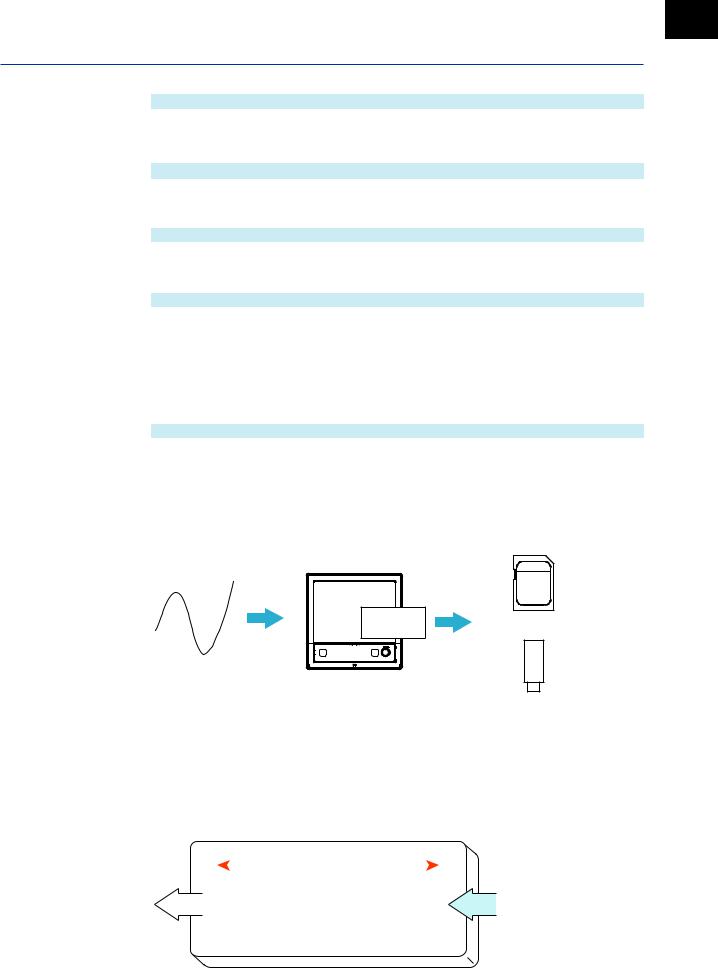

Appendix 4 FIFO Data Output Flow Chart Overview of the FIFO Buffer The recorder internal memory is equipped with a dedicated FIFO (First-In-First-Out) buffer for outputting measured data. Measured data is written to the buffer at every scan interval. The PC can continuously retrieve the most recent measured data from the FIFO buffer. The size of the internal memory allocated for the FIFO buffer varies depending on the model.

-

Page 209: Appendix 5 Check Sum Calculation Method

Appendix 5 Check Sum Calculation Method The check sum of binary data is calculated using an algorithm like the one shown below. int CalcSum(unsigned char *buf, int len) odd; unsigned long sum; unsigned char sum = 0; odd = len & 1; len >>= 1;…

-

Page 210: Appendix 6 Data Group Name And Data Name For Wt Communication

Appendix 6 Data Group Name and Data Name for WT Communication The table below shows the parameters p5 (Data Group Name) and p6 (Data Name) for SWattData Command. Parameters p5 (Data Group Name) and p6 (Data Name) for SWattData Command WT1800 p5 (Data group name) p6 (Data name)

-

Page 211

Appendix 6 Data Group Name and Data Name for WT Communication Data group name Data name Description WT Function mark η 1 Other ETA1 Efficiency 1 η 2 ETA2 Efficiency 2 η 3 ETA3 Efficiency 3 η 4 ETA4 Efficiency 4 User-defined function 1 User-defined function 2 User-defined function 3… -

Page 212

Appendix 6 Data Group Name and Data Name for WT Communication WT500 Data group name Data name Description WT Function mark Data assignment is disabled. – ELEMENT to ELEMENT3 URMS True rms voltage Urms Rectified mean voltage calibrated to the rms value Simple voltage average URMN Rectified mean voltage… -

Page 213

Appendix 6 Data Group Name and Data Name for WT Communication Data group name Data name Description WT Function mark φ U(3) ElemHrm1 to ElemHrm3 PHIUk3 Phase difference between harmonic voltage U(3) and the fundamental signal U(1). φ I(3) PHIIk3 Phase difference between harmonic current I(3) and the fundamental signal I(1). -

Page 214

Appendix 6 Data Group Name and Data Name for WT Communication Data group name Data name Description WT Function mark φ U1-I2 Phase PHI_U1I2 The phase difference between the fundamental voltage of element 1, U1(1), and the fundamental current of element 2, I2(1) φ… -

Page 215